Verified & Reviewed

Published on November 7, 2025 Written By Meredith Flora

Published on November 7, 2025 Written By Meredith Flora

Subscribe for More

AI has taken the world by storm. Whether it be for writing product descriptions, predicting demand, delivery route optimization, or even helping customers find the right size shoe, it’s quickly becoming a must-have tool in ecommerce. In fact, it’s estimated that 35% of businesses have already adopted some form of AI.

But what about AI in logistics?

In the logistics industry, AI is quietly transforming how ecommerce brands operate. It’s helping teams better manage inventory, speed up fulfillment, and scale without the growing pains.

At ShipBob, we work with thousands of ecommerce brands to help them build more efficient supply chains. And we’ve seen firsthand how AI is changing the game. In this guide, we’ll break down what AI in logistics really means, how it compares to traditional automation, and where ecommerce businesses are using it today to gain a competitive edge.

What is AI in logistics?

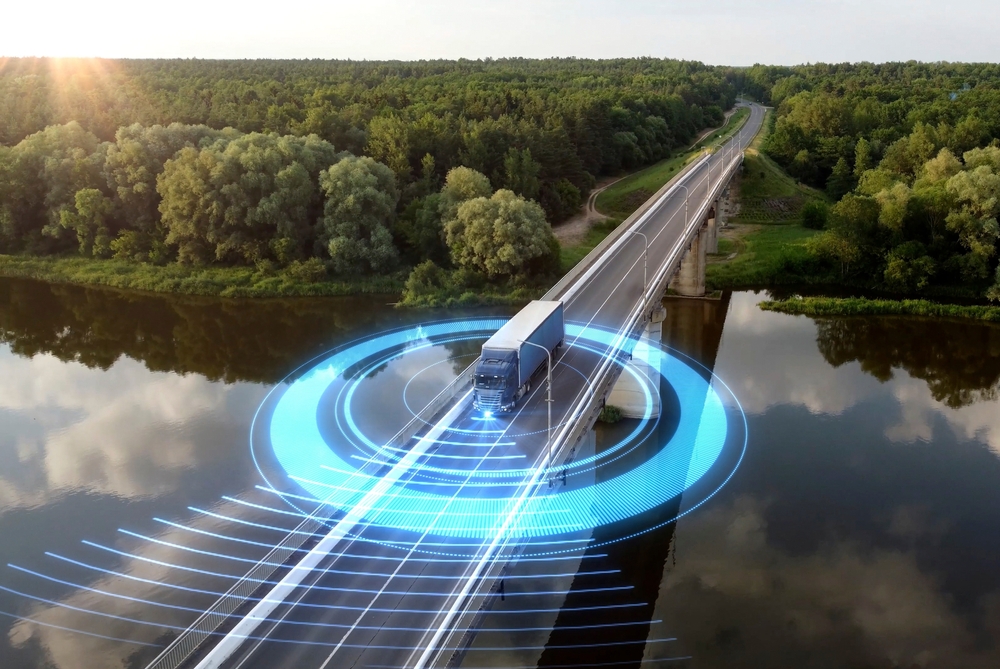

AI in logistics refers to the use of artificial intelligence technologies, such as machine learning (ML), natural language processing, and predictive algorithms, to optimize supply chain operations. This can include everything from forecasting demand and improving inventory management to automating order routing and optimizing carrier selection.

Unlike traditional systems, AI isn’t just following rules; it’s learning from data, recognizing patterns, and making increasingly better decisions over time.

This shift toward digital logistics is revolutionizing how ecommerce brands manage fulfillment, respond to disruptions, and scale globally.

How AI differs from traditional methods/is transforming supply chains

Traditional logistics systems are linear and reactive. They require constant human input, manual updates, and fixed business rules that struggle to keep up with dynamic ecommerce environments.

AI changes this.

AI can continuously learn from new data, identify subtle patterns that might escape human analysis, and adapt its recommendations. This approach is transforming how businesses track, manage, and make decisions across their logistics operations in several key ways:

- Speed: AI processes and analyzes data at scale in seconds, far faster than human teams or legacy systems.

- Accuracy: AI-powered demand forecasting reduces stockouts and overstock by detecting patterns that human analysts might miss.

- Scalability: As your business grows, AI systems scale without adding headcount or complexity.

AI vs. automation in supply chain logistics

While often used interchangeably, AI and automation represent different (though complementary) approaches to supply chain transformation.

Automation focuses on executing repetitive tasks according to pre-defined rules. A warehouse management system (WMS) that automatically generates pick lists based on order priority is an example of automation. It’s efficient and reduces manual effort, but it doesn’t necessarily “learn” or improve over time without human intervention.

Automation is best for:

- Repeatable, rule-based processes

- Tasks with clear inputs and outputs

- Situations where consistency is important

AI, on the other hand, brings a layer of intelligence and adaptability to automated systems. For example, through predictive modeling, an AI-enhanced WMS could analyze historical data to forecast which SKUs are likely to be ordered together during an upcoming promotion. It could then recommend placing those items closer together in the warehouse to speed up picking.

AI is best for:

- Complex decision-making with multiple variables

- Scenarios requiring prediction or forecasting

- Situations that benefit from continuous learning and improvement

How AI can benefit logistics and supply chains

AI technologies deliver some serious value when it comes to logistics and supply chain management. Let’s look at how it helps ecommerce brands move faster, reduce errors, cut costs, and scale smarter.

Faster and more accurate fulfillment

AI solutions can help speed up fulfillment by routing orders to the best warehouse based on inventory, location, and delivery time.

It also improves picking efficiency by learning which products are ordered together and optimizing workflows. Some systems even use computer vision to verify items before they’re packed—cutting down on mistakes.

On top of that, AI can spot bottlenecks in real time and suggest quick fixes (for example, identifying that a certain SKU is frequently causing delays due to its location, then recommending it be moved closer to the packing area to speed up the process).

Enhanced demand forecasting

Leveraging the power of AI for demand forecasting can significantly improve how ecommerce brands manage inventory and plan ahead.

Instead of relying solely on historical sales data, AI can analyze a wide range of variables, like seasonality, social trends, marketing campaigns, and even weather patterns, to predict demand more accurately.

This allows businesses to stock the right products, in the right quantities, at the right locations.

Cost efficiency through optimization

AI algorithms can help logistics companies reduce shipping and operational costs by optimizing everything from delivery routes to labor schedules.

It identifies the most cost-effective carriers, predicts busy periods to improve staffing, and even helps manage warehouse energy use. Plus, it keeps inventory levels balanced across multiple locations, cutting down on unnecessary transfers and holding costs.

Scalability alongside success

As your brand grows, your logistics systems need to grow with you. AI makes that easier than ever before.

It automatically adjusts to higher order volumes, supports market expansion, and reallocates resources on the fly. The more data it gets, the better it performs.

This built-in scalability makes AI ideal for ecommerce brands looking to expand without constantly reworking their operations.

Real-life applications of AI in logistics and supply chains

While the benefits sound promising, what does AI look like in action? Here are some concrete examples of how businesses are applying artificial intelligence to transform their logistics operations.

AI for warehouse automation

Modern warehouses are becoming increasingly intelligent, with AI driving various automation systems, such as:

- Autonomous mobile robots (AMRs): AI-guided robots can navigate warehouse floors, retrieve items, and transport them to packing stations.

- Intelligent picking systems: Computer vision combined with AI helps workers identify items faster and with fewer errors.

- Dynamic slotting: AI continuously analyzes picking patterns and recommends optimal item placement within the warehouse.

Route and carrier optimization

Getting products from warehouses to customers efficiently is another area where AI shines. Here are some real-world ways AI is making last-mile delivery smarter and more cost-effective:

- Dynamic route planning: AI can factor in traffic patterns, weather conditions, and delivery time windows to create optimal delivery routes.

- Carrier selection: Machine learning algorithms can predict which shipping carriers will provide the best combination of cost, speed, and reliability for specific shipments.

- Load optimization: AI can determine the most efficient way to pack delivery vehicles, maximizing capacity while ensuring package safety.

- Delivery time prediction: AI models provide more accurate delivery time estimates, improving customer satisfaction.

Predictive analytics in supply chains

Yet another powerful application of AI in logistics is its ability to see around corners through predictive supply chain analytics. Some examples include:

- Disruption prediction: AI can identify potential supply chain disruptions before they occur, allowing for proactive mitigation.

- Inventory optimization: Predictive models ensure you have the right products in the right locations at the right time.

- Customer behavior modeling: AI can predict changing customer preferences and help you adapt your inventory strategy accordingly.

This kind of forward-thinking turns logistics from a reactive chore into a real competitive edge. With AI-driven insights powering lean logistics, brands can cut out the waste and still deliver faster, smarter service.

Challenges and considerations when implementing AI

Despite its potential, implementing AI in logistics isn’t without challenges. Here are some considerations to keep in mind.

Data integration and accuracy

AI can only be as smart as the data it’s working with, which is where things can get tricky. One major challenge is that data often lives in silos across different platforms that don’t talk to each other. If your inventory data lives in one place and your order data somewhere else, AI can’t work its magic.

Then there’s the issue of data quality. Inaccurate, outdated, or inconsistent info leads to unreliable predictions and bad decision-making. Even if your data is solid, actually connecting legacy systems to modern AI tools can take some technical effort.

These challenges aren’t impossible to fix; in fact, leveraging a central WMS that pulls data from multiple sources and keeps everything in sync can make a huge difference. It creates a single source of truth for inventory, orders, and fulfillment activity, giving AI the clean, connected data it needs to deliver accurate insights.

Upfront costs and ROI

Another challenge to consider is that AI can come with a steep learning curve and upfront investment. The tech itself (software, hardware, integrations) isn’t always cheap, and you might need specialized talent to get things running smoothly.

Additionally, there can also be some short-term disruption while new systems are rolled out and your team adjusts. And while AI implementation can absolutely pay off, the ROI isn’t always immediate. It may take a little time for the system to learn, optimize, and deliver consistent results.

For many ecommerce brands, the smarter move is to partner with a 3PL or fulfillment provider that already has these types of systems built into their operations. That way, you get the benefits without having to build everything from scratch.

How ShipBob leads and exceeds the AI logistics revolution

At ShipBob, we believe supply chain technology should be accessible, scalable, and built for modern ecommerce brands. Whether you’re fulfilling orders yourself or outsourcing to us, our tools offer AI-level intelligence without the complexity or cost of building it all from scratch.

Achieve AI-level efficiency with ShipBob’s WMS

Whether you’re managing your own warehousing or outsourcing fulfillment entirely, ShipBob gives you access to AI-powered logistics tools that streamline operations and support scalable growth.

With ShipBob’s WMS, you can:

- Gain access to real-time inventory tracking across multiple locations to ensure accurate stock levels.

- Leverage intelligent fulfillment rules and batch picking capabilities to optimize fulfillment workflows

- Benefit from label generation and carrier selection reduce shipping costs while improving delivery times.

No matter how you choose to fulfill orders, ShipBob WMS brings supply chain automation to businesses of all sizes. Helping delivers the efficiency, speed, and control modern ecommerce brands need to compete and grow.

Scale globally with ShipBob’s fulfillment network

For brands ready to scale, ShipBob’s network of 60+ fulfillment centers across the US, Canada, Europe, and Australia provides an instant path to global growth without the need to build out international infrastructure.

By storing inventory closer to your customers around the world, you can reduce shipping times, lower costs, and improve the overall delivery experience. With full visibility across locations, expanding into new markets becomes faster, easier, and far less risky.

Deliver on customer expectations with seamless logistics

Today’s customers expect fast, accurate, and transparent delivery. ShipBob’s fulfillment tech helps brands deliver on those expectations.

Our optimized pick-and-pack workflows reduce errors and speed up processing, while real-time tracking keeps both you and your customers in the loop.

On top of that, ShipBob’s Inventory Placement Program (IPP) is powered by our AI Decision Engine, which pulls information from our demand forecasting algorithms, your historical sales trends by SKU, and real-time sales data, using a time-series forecasting model to account for seasonality. By leveraging IPP, brands can automatically distribute inventory and ensure products are always stocked where they’re needed most.

Don’t wait to optimize your supply chain

Whether you’re dealing with seasonal spikes, expanding into new markets, or keeping up with rising customer demands, optimizing your supply chain now sets the stage for long-term success.

ShipBob supports brands at every stage. If you’re fulfilling in-house, our WMS brings AI-level efficiency with real-time tracking and smart automation. For fast-growing brands or seasonal peaks, outsourcing to ShipBob’s network keeps things running smoothly. And for businesses ready to scale big, our end-to-end fulfillment lets you focus on growth while we handle the rest.

“We’ve scaled so much, and there have been zero hiccups in fulfillment with ShipBob. I don’t think even as we keep scaling in the years to come that there will be any hiccups there. That cannot always be said of brands that run their own warehouse. Running your own warehouse, you have to go out and hire very experienced people, invest in equipment, build in automation – and often, you’re wasting a lot of time, energy, resources, and human capital for a sub-par result. Why do that when a partner like ShipBob exists, and makes fulfillment so easy at a fair price?”

Tyler McCann, Co-Founder of Taste Salud

Get started with ShipBob today!

Want to deliver AI-level logistics without building it from scratch? Explore ShipBob’s fulfillment solutions to future-proof your supply chain and grow your business with confidence.

AI in logistics FAQs

How are businesses implementing AI in ecommerce logistics?

Ecommerce brands use AI to forecast demand, optimize inventory placement, automate fulfillment, and improve delivery routing. It’s especially common in areas like real-time inventory tracking and predictive analytics.

Can AI predict process bottlenecks and prevent high-stress supply chain and logistics scenarios?

Yes. AI systems analyze data from multiple sources to detect potential slowdowns—like warehouse congestion, carrier delays, or low stock—and suggest solutions before they become problems.

Can AI be used to enhance supply chain transparency?

Absolutely. AI improves supply chain visibility by tracking inventory across channels and locations in real time, helping brands spot gaps or inefficiencies early.

How can ShipBob help with AI-powered logistics?

ShipBob uses next-gen tech and automation to power smarter, faster, and more scalable ecommerce fulfillment.

Most notably, ShipBob’s Inventory Placement Program (IPP) is powered by our AI Decision Engine, which pulls information from our demand forecasting algorithms, your historical sales trends by SKU, and real-time sales data, using a time-series forecasting model to account for seasonality.

Whether through our WMS or fulfillment network, we help ecommerce brands gain the benefits of AI without the complexity or cost of building it in-house.