Verified & Reviewed

Published on September 2, 2025 Written By Melissa Nick

Published on September 2, 2025 Written By Melissa Nick

Subscribe for More

Hear from Melissa Nick, ShipBob’s Chief Supply Chain Officer, on what supply chain trends we’ve seen over the last year, what brands are looking for in their logistics, and the capabilities ShipBob is investing in now to prepare for the future.

From Day One to Today: My Journey in Fulfillment

I started my supply chain career in manufacturing, cutting my teeth in the industry and gaining foundational knowledge before eventually moving to Amazon. I spent nearly a decade there, and my team scaled their network and often shipped over 50 million items a day – so when I joined ShipBob, I was ready to hit the ground running.

My first day at ShipBob coincided with the kickoff of our annual merchant event, Fulfilled. As soon as I walked into my new job, I was surrounded by merchants sharing their challenges and asking, “What are you going to do about it, Melissa?”

Fast forward two years, and we’ve done a lot about it. Time has flown by, and I’m thrilled to tell you how we’re building a chaos-proof fulfillment network, and to let you in on ShipBob’s roadmap for 2026 and beyond.

ShipBob’s 3 Supply Chain Bets from 2024 (and How They’ve Paid Off)

Last year, I made bold commitments on stage at Fulfilled, and I’m proud to say we delivered.

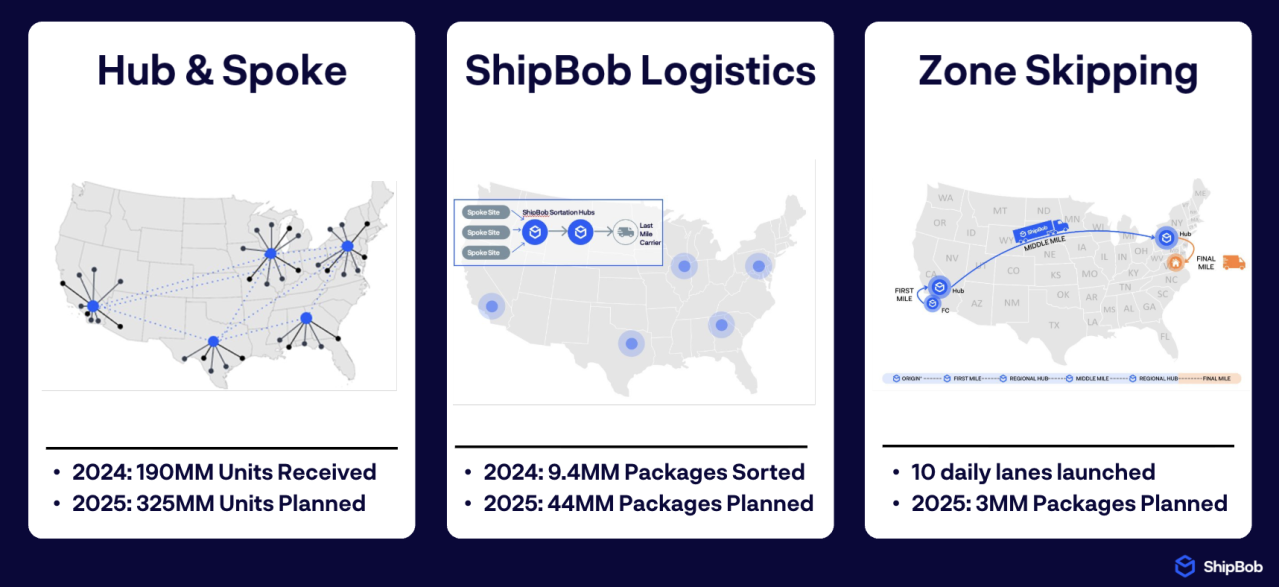

Our team looked at the state of supply chain and, in tandem with feedback from our merchants, invested into three major initiatives: our hub-and-spoke network, ShipBob Logistics, and zone skipping.

Expanding the Hub-and-Spoke Network

We expanded our hub-and-spoke network and simplified North American receiving by routing everything through our hub receiving sites. Today, hundreds of millions of items move through this network, completely blowing away our past volumes and improving efficiency for thousands of merchants.

Unlocking Outbound Efficiency with ShipBob Logistics

With our hub-and-spoke network optimizing inbound, we asked ourselves: how can we leverage it for outbound as well? Our team developed ShipBob Logistics (SBL): a sortation solution designed to streamline outbound shipping for speed and cost.

With ShipBob Logistics, we’ve gone big. We launched four sort centers, which has improved carrier tracking and enabled us to inject into several additional carriers. Our customer delivery experience is now 130 basis points better than direct carrier injections – proof that we’re better stewards of merchant’s packages because of SBL.

Zone Skipping: A Game Changer

Zone skipping has transformed how we move packages.

For instance, say a merchant has inventory stored in the Northeast, and an order needs to be shipped to a customer in Dallas, TX. Instead of shipping from the Northeast to Dallas via a carrier, we now load packages into our own trucks (bound for Dallas anyway as part of our inbound inventory placement program), transport them to Dallas, and inject them locally.

This drastically reduces a merchant’s average shipping zone, their shipping transit times and costs, and improves the overall customer experience.

The 4 R’s for Future-Proofing Supply Chains

ShipBob’s teams are already working on how to future-proof our merchants’ supply chains this upcoming year and beyond.

As we continue to build out new capabilities, there are 4 things that our solutions – and we ourselves – must be to succeed in the evolving supply chain landscape.

1. Responsive: Scaling B2B with Precision

We’ve seen our merchants working hard to expand in the B2B space, and it’s no surprise why. Retail is booming – our B2B order volumes have grown over 250% – and we’ve expanded our B2B solution to keep up with and support merchants’ growth. We’re investing in:

- Load Management: Capturing BOLs, seal numbers, and other attributes at the load level.

- Retail Compliance: Automating retailer-specific requirements for 150+ retail partners (with more being added all the time) through our WMS.

- B2B Order Modification: Allowing short-shipping and/or changes even after packing.

2. Resilient: Leveraging AI for Smarter Fulfillment

AI isn’t just a hot-button buzzword; it’s a major leap forward in time management for ecommerce logistics and offers efficiency gains on a massive scale. We’re already taking steps to embed it in our operations, including:

- Retailer AI: AI scrubs retailer compliance guides to generate accurate, actionable instructions in a fraction of the time.

- Photo Review Automation: AI reviews photos we take of B2B orders (when pallets are staged and loaded) to flag issues before they make it onto the truck, saving hours of manual auditing.

- Order Attachment Scanning: AI scans order attachments to ensure all information is correct and no documentation is missing, boosting accuracy and preventing issues down the road.

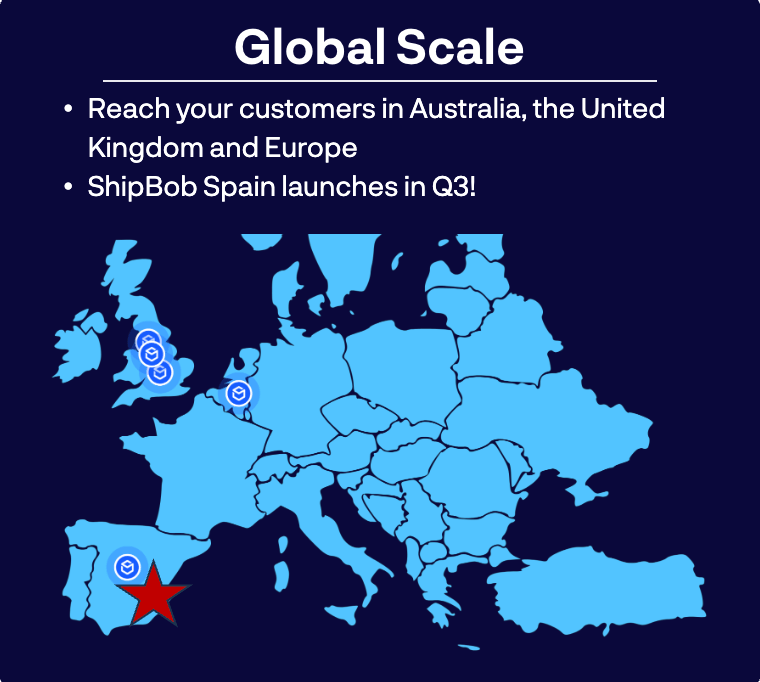

3. Reliable: Global Expansion and Compliance

Our international teams in the UK, EU, Canada, and Australia are always working to make it easier for merchants to expand globally. For instance, in direct response to merchant feedback, we’re launching a new fulfillment center in Spain to help brands reach customers in Southern Europe even faster.

We’re also doubling down on compliance, investing in:

- GMP and GFSI Certifications: Offering GMP- and GFSI-certified sites in every region to deliver the foundational structure and food-specific regulatory requirements for quality warehousing (so you don’t have to).

- Hazmat Storage: Offering HAZMAT-qualified storage locations in every region, to track goods and ensure we are prioritizing safety of our employees and merchant’s inventory.

- Dangerous Goods (DG) Shipping: Facilitating DG-compliant shipments with additional carrier and technology offerings.

- Free Trade Zone (FTZ) Warehousing: Helping brands navigate the de minimis changes implemented in August 2025 to optimize cashflow and minimize tariffs and duties.

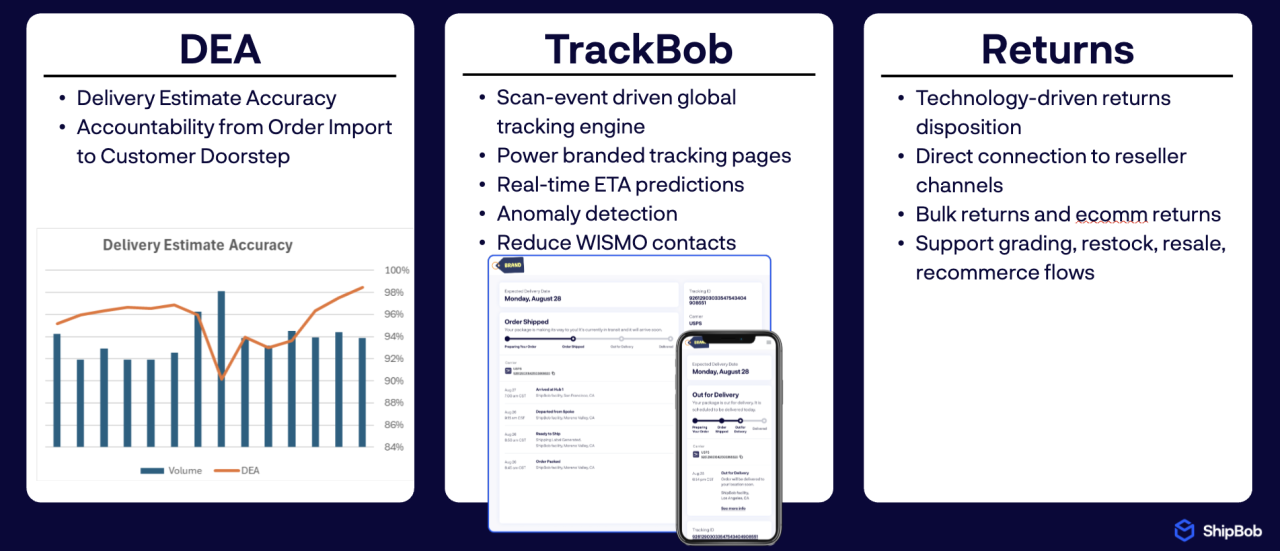

4. Relationship-Driven: Delivering Customer Confidence at Every Touchpoint

At ShipBob, our job doesn’t stop once a shipment gets a tracking number; instead, we own the full journey to the customer doorstep. We’re working to deliver end-to-end tracking and control from the moment the order is imported into our system to the moment it is delivered. This includes:

- Tracking Delivery Estimate Accuracy (DEA): Measuring, reporting on, and improving how often we’re getting packages delivered by the time we estimated (we’re hitting 98%, on par with Amazon).

- TrackBob: A custom-branded, unified tracking page for your customers to provide peace of mind without juggling multiple platforms or sources of tracking information.

- Maximizing Value From Returns: Integrating with platforms like GiveNKind, making it cheaper to donate than to dispose.

- Fast Track Receiving: Receiving and stowing organized, advance-notice inventory in only a day (especially beneficial for high-volume merchants).

- Optimizing Picking for Efficiency: Implementing new technology and separating different types of picking (e.g., singles pick, multi pick, zone pick, etc.) to increase throughput for our network.

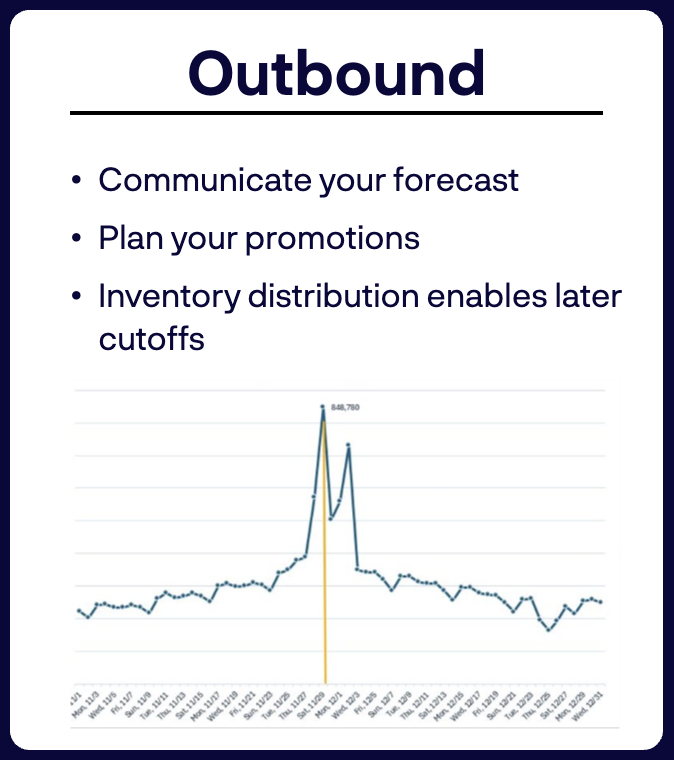

Prepared for Peak 2025?

Peak is just 11 weeks away. We are in the thick of planning at ShipBob – our machine learning models are forecasting inbound and outbound volumes with precision, and we’re looking at our biggest holiday surge yet.

If your brand hasn’t prepared for peak, don’t worry (yet). You should start by:

- Sending inventory in early: Make sure you know what your receiving deadlines are. ShipBob never stops receiving (even through Christmas Eve!), but the sooner you get your inventory into ShipBob’s network, the less crunched-for-time you’ll be to run holiday promotions.

- Leverage the Inventory Placement Program to allocate inventory strategically: By getting your inventory closer to your end customers, you can majorly reduce your transportation costs and extend holiday shipping cutoffs.

- Share your promotional calendar and forecasts ahead of time: We’ll inject the data you give us into our ML model to make sure we have the most accurate predictions possible.

Building the Future of Supply Chain, Together

At ShipBob, we aim to be the invisible execution behind a brand’s success. All of our investments, both past and present, are inspired by our merchants: what they need, what they value, and how we can make their job easier.

Real feedback shapes our roadmap and informed all the advancements I’ve talked about. I can’t wait for next year, when I’ll be back to share how we turned this year’s insights into action, and continued to build the future of supply chain together.