Verified & Reviewed

Last updated on December 22, 2025 Written By Meredith Flora

Last updated on December 22, 2025 Written By Meredith Flora

Subscribe for More

In ecommerce, few things erode customer trust faster than a missed delivery promise.

Whether an order arrives days late or unexpectedly early, every mismatch between the promise and reality chips away at confidence in your business. That’s why improving DEA isn’t just a logistics goal; it’s a strategic priority.

In this guide, we’ll break down what DEA is, why it matters, and how ecommerce brands can get it right. With insights from ShipBob’s industry-leading fulfillment network, you’ll learn how better delivery estimates can create better customer relationships.

What does delivery estimate accuracy mean?

Delivery estimate accuracy (DEA) refers to the ability of an ecommerce business to correctly predict when a customer’s order will arrive at their doorstep. This metric is typically measured as the percentage of orders that are delivered within the promised timeframe provided to the customer at checkout.

For example, if a brand promises delivery within 3-5 business days and 95% of their orders arrive within that window, their DEA would be 95%. The higher the percentage, the more accurate and reliable the delivery estimates are.

Why does delivery estimate accuracy matter?

Accurate delivery estimates are crucial for building customer trust, satisfaction, and loyalty. When customers have a clear and reliable expectation of when their order will arrive, they can plan accordingly and feel confident in their purchase decision.

On the other hand, inaccurate estimates can lead to frustration, disappointment, and even lost trust in the brand. Imagine eagerly anticipating a package for a specific occasion, only to have it arrive days later than promised. Or planning your week around a delivery, only to have it show up unexpectedly early when you’re not home to receive it.

These negative experiences can erode customer confidence and make them less likely to shop with the brand again. In fact, 85% of consumers are unlikely to shop with a brand again after just one poor delivery experience.

Accurate delivery estimates have become table stakes in today’s “Amazon-conditioned” market, where customers expect fast, reliable, and predictable shipping. Brands that consistently meet or exceed these expectations can differentiate themselves and build a loyal customer base.

Moreover, accurate estimates can also reduce the burden on customer support teams. When deliveries arrive on time as promised, customers are less likely to reach out with inquiries or complaints about their order status. This frees up support resources to focus on more complex issues and proactive customer engagement.

How does delivery estimate accuracy impact the customer experience?

From the moment an order is placed until it arrives at the customer’s door, delivery expectations set the tone for how the customer feels about their interaction with the brand.

When a customer has a clear and reliable estimate of when their order will arrive, they feel a sense of anticipation and excitement. They trust that the brand will follow through on its promise and deliver their order as expected.

However, when estimates are inaccurate or unreliable, customers are left in a state of uncertainty and anxiety. They may feel the need to constantly check their order status or reach out to customer support for updates. This creates a negative association with the brand and erodes trust.

Accurate delivery estimates also play a crucial role in setting proper expectations. When a brand consistently meets or exceeds its promised delivery dates, customers learn to trust those estimates as reliable. This builds confidence in the brand’s capabilities.

Factors that influence delivery estimate accuracy

Accurately predicting delivery times in modern ecommerce is a complex challenge, as delivery estimate accuracy is affected by both internal (controllable) and external (less controllable) factors. Understanding these factors is the first step toward improving accuracy and providing customers with reliable delivery estimates they can trust.

Inventory management and visibility

Effective inventory management is the foundation of accurate delivery estimates. Real-time inventory accuracy prevents stockouts that can compromise delivery promises and leave customers disappointed. Maintaining adequate safety stock levels and accurate forecasting helps prevent backorders that can lead to missed delivery estimates.

Fulfillment operations efficiency

The speed and consistency of order processing directly impact delivery timelines. Establishing clear cut-off times for same-day processing sets customer expectations and influences promised ship dates. Optimizing pick, pack, and ship workflows for efficiency and accuracy helps ensure orders leave the warehouse on time.

Also, leveraging strategically located fulfillment centers can also reduce transit times and improve delivery estimate accuracy.

Carrier selection and performance

The carriers you choose to work with play a significant role in delivery estimate accuracy. Each carrier has its own method for calculating estimated delivery dates, and performance can vary by region, service level, and time of year.

Diversifying your carrier mix can help maintain DEA during disruptions, as you can route orders to the most reliable option. Integrating with carrier tracking APIs also enhances visibility and prediction accuracy.

External disruptions and seasonality

Even the most efficient fulfillment operations can be impacted by external factors beyond their control. Weather events, traffic delays, and labor issues can all affect delivery timelines. Peak seasons like holidays and major sales events put added pressure on carrier capacity and can compromise delivery accuracy.

Global events such as pandemics and supply chain disruptions introduce additional variables. Building buffer time into estimates during high-risk periods can help manage customer expectations.

Technology infrastructure

The right technology infrastructure is essential for maintaining delivery estimate accuracy at scale. Shipping and fulfillment software that provides real-time data and analytics helps improve prediction capabilities. Machine learning and AI are revolutionizing delivery estimate calculations by analyzing vast amounts of historical data to generate more precise predictions.

Seamless integration between systems like order management (OMS), warehouse management (WMS), and transportation management (TMS) enables end-to-end visibility and data accuracy.

Are estimated delivery dates accurate? Evaluating carrier performance

When it comes to the accuracy of estimated delivery dates, it’s important to understand that performance can vary significantly across different carriers. While major carriers like UPS, USPS, and FedEx have invested heavily in technology and infrastructure to improve their prediction capabilities, no carrier can guarantee 100% accuracy in all circumstances.

UPS delivery estimate accuracy

UPS is known for its robust tracking capabilities and generally reliable delivery estimates. According to their own performance metrics, UPS achieves on-time delivery rates of over 96%.

UPS’s advanced analytics and machine learning algorithms help them continuously refine their estimates based on real-time data, but some variability is still to be expected.

USPS delivery estimate accuracy

As a government-operated carrier, USPS faces some unique challenges when it comes to delivery estimate accuracy. While their Priority Mail and First-Class services are generally reliable, USPS’s estimates can be less precise for lower-cost options like Parcel Select or for deliveries to remote rural areas.

USPS also has limited tracking capabilities compared to private carriers, which can make it harder for customers to monitor progress and adjust expectations. However, USPS does offer competitive rates and delivery times for many types of shipments.

FedEx delivery estimate accuracy

FedEx is another major player in the shipping industry, with a reputation for fast and reliable service. Their on-time delivery rates are consistently high, often exceeding 97%. FedEx’s advanced tracking technology and proactive communication help keep customers informed of any shipping delays or changes to estimated delivery times.

However, like all carriers, FedEx can experience occasional hiccups due to factors outside their control, such as adverse weather conditions or unexpected volume surges.

Regional and specialty carriers

While the big three carriers dominate the shipping landscape, there are many regional and specialty carriers that offer competitive services and often better delivery estimate accuracy for certain types of shipments. These smaller carriers may have more localized infrastructure and expertise, allowing them to provide more precise estimates and faster delivery times within their coverage areas.

Specialty carriers, such as those focused on perishable goods or high-value items, may also have tailored services and handling procedures that enhance accuracy and reliability. By strategically combining different carriers based on their strengths and performance in various regions or product categories, ecommerce businesses can optimize their overall delivery estimate accuracy.

How to measure and improve your delivery estimate accuracy

Measuring and improving delivery estimate accuracy is crucial for providing a superior customer experience and building long-term brand loyalty. By establishing baseline metrics, setting appropriate targets, and implementing a systematic approach to continuous improvement, ecommerce businesses can significantly enhance their DEA performance.

1. Establish key performance indicators (KPIs)

To effectively measure and improve your delivery estimate accuracy, it’s essential to establish a set of key performance indicators that provide a comprehensive view of your fulfillment performance. Some of the most important DEA metrics to track include:

- On-time delivery rate: The percentage of orders delivered within the promised time frame

- Average delay time: The average number of days beyond the estimated delivery date that orders are arriving

- Carrier performance: On-time rates and average delays segmented by individual carriers

- Regional performance: DEA metrics broken down by geographic regions or shipping zones

By segmenting these metrics by carrier, region, product type, and service level, you can gain a more nuanced understanding of where improvements are needed. For example, you may find that certain carriers consistently underperform in specific regions or that particular products are more prone to delays due to their size or fragility.

To make tracking and analyzing these KPIs as efficient as possible, consider creating a centralized DEA dashboard that provides real-time visibility into key metrics. This dashboard should integrate data from various sources, such as your order management system, warehouse management system, and carrier APIs, to provide a holistic view of performance.

2. Implement real-time tracking and visibility

Customers expect real-time visibility into the status of their orders. By providing accurate, up-to-date tracking information, businesses can not only improve the actual accuracy of their delivery estimates but also enhance the perceived reliability of their fulfillment process.

To implement real-time tracking, you’ll need to integrate your systems with carrier APIs that provide live updates on package status and location. This integration can be complex, requiring technical expertise and resources to ensure seamless data flow and accuracy. However, the benefits of real-time tracking are well worth the investment.

Once you have tracking data flowing into your system, it’s important to present this information to customers in a clear, accessible format. Consider creating a dedicated tracking page on your website or app that allows customers to easily view the current status of their orders and estimated delivery dates.

You may also want to provide proactive updates via email or SMS, particularly if there are any delays or changes to the original estimate.

3. The multi-location fulfillment advantage

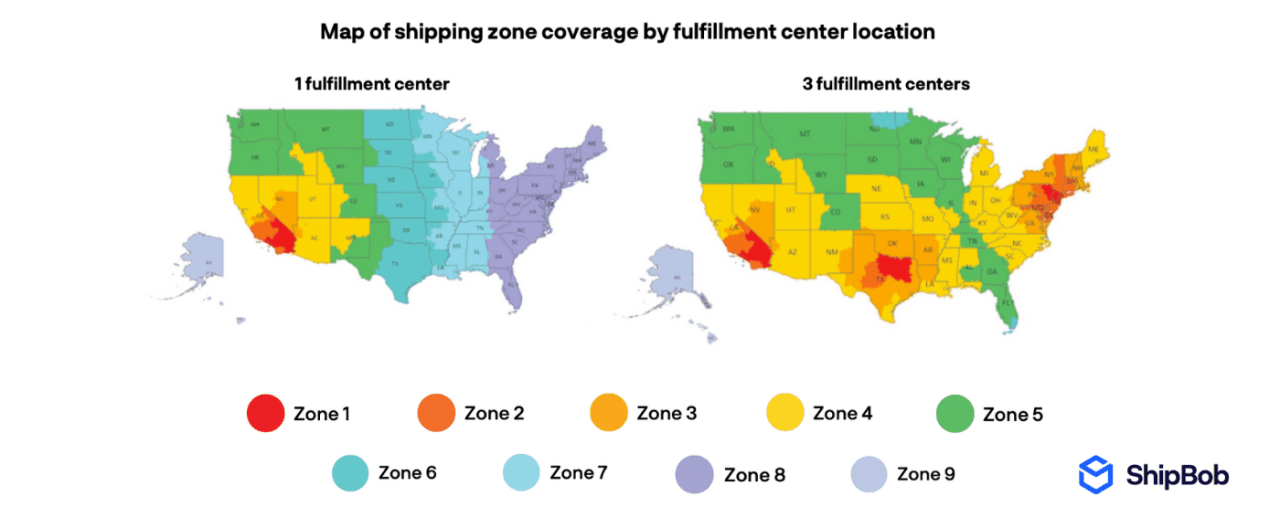

One of the most effective strategies for improving delivery estimate accuracy is to distribute inventory across multiple fulfillment centers located strategically throughout your target market(s). By storing products closer to end customers, you can significantly reduce transit times and minimize the risk of delays due to distance or regional disruptions.

This multi-location fulfillment approach also allows you to take advantage of the combined performance of multiple facilities can outpace that of a single, centralized warehouse. With the right technology in place to route orders intelligently based on factors like inventory availability, carrier performance, and customer location, you can optimize your fulfillment network for maximum speed and accuracy.

When determining the optimal locations for where to place your inventory, consider factors such as population density, transportation infrastructure, and proximity to carrier hubs. You may also want to analyze your historical sales data to identify regions where you have a high concentration of customers or where delivery estimate accuracy has been a challenge in the past.

4. Create buffer strategies without sacrificing speed

One of the challenges in improving delivery estimate accuracy is balancing the desire for speed with the need for realistic, achievable timelines. While it may be tempting to provide overly optimistic estimates to attract customers, this approach can backfire if you fail to meet those expectations.

To strike the right balance, consider building buffer strategies into your delivery estimates that account for potential delays or disruptions without sacrificing overall speed. For example, you might add an extra day or two to your standard processing time to allow for unexpected issues like inventory discrepancies or poor weather conditions. You can then use this buffer to under-promise and over-deliver, which can help build trust and loyalty with customers.

Another approach is to use dynamic buffer calculations that adjust based on real-time data and conditions. For instance, during peak seasons or in regions where carrier performance has been historically inconsistent, you might automatically add additional time to your estimates to account for potential delays. By leveraging machine learning algorithms and predictive analytics, you can continually refine these buffer strategies over time.

Best practices for communicating delivery timelines to customers

By providing clear, accurate, and timely information about delivery timelines throughout the entire customer journey, ecommerce businesses can set proper expectations and proactively address potential issues before they escalate.

Pre-purchase delivery information

To set the stage for a positive experience, it’s crucial to provide clear, accurate delivery information on product pages and throughout the checkout process.

On product pages, consider displaying estimated delivery dates or ranges based on the customer’s location and the product’s availability. Be sure to clearly communicate any cut-off times for same-day processing or expedited shipping options. If a product is backordered or on pre-order, make this information prominent and provide realistic timelines for when the item will be available to ship.

During checkout, reiterate the estimated delivery date and provide options for faster shipping if desired. If you offer free shipping promotions or guaranteed delivery dates, make sure these are clearly communicated and that any associated terms and conditions are easy to understand.

Order confirmation and tracking communications

Once an order is placed, the next critical touchpoint is the order confirmation email. This message should include a summary of the purchased items, the estimated delivery date, and any tracking information available at that time. If the order will be shipped in multiple packages or from different locations, make this clear upfront to avoid confusion.

As the order progresses through the fulfillment process, provide regular updates to keep customers informed. Consider sending a notification when the order is processed and ready for shipment, along with the carrier and tracking number. From there, proactive updates can be triggered based on key milestones like when the package is out for delivery or when it has been successfully dropped off.

In addition to email notifications, consider providing a self-service tracking page on your website or app where customers can view real-time status updates and estimated delivery dates. This page should be easy to access from the order confirmation email and should include clear explanations of any delays or changes to the original estimate.

Proactive delay management

Despite best efforts, delays can still occur due to factors outside of your control, such as weather disruptions or carrier issues. When this happens, it’s essential to communicate proactively with customers to minimize frustration and maintain trust.

Develop a clear protocol for identifying and communicating delays before customers reach out with inquiries. This may involve setting up automated alerts based on carrier data or monitoring social media channels for mentions of delivery issues. Once a delay is identified, reach out to affected customers as quickly as possible with a clear explanation of the situation and a revised delivery estimate.

Consider creating email and SMS templates for different delay scenarios to ensure consistent and accurate messaging. These templates should include an apology for the inconvenience, a brief explanation of the cause of the delay, and any steps being taken to resolve the issue. If the delay is significant or if the order is time-sensitive, you may also want to offer compensation such as a discount code or free expedited shipping on a future purchase.

Post-delivery follow-up

The delivery experience doesn’t end when the package arrives at the customer’s doorstep. To fully optimize the customer journey and gather valuable feedback, consider implementing a post-delivery follow-up process.

This can be as simple as sending an email to confirm that the order was successfully delivered and to thank the customer for their business. You may also want to include a brief survey or request for feedback on the delivery experience, which can provide insights into areas for improvement.

For customers who had a particularly positive experience, consider asking them to leave a review or share their feedback on social media. Positive reviews and testimonials can be powerful social proof for future customers and can help build trust in your brand’s delivery capabilities.

On the other hand, if a customer reports a negative delivery experience, take the time to follow up personally and address their concerns. This shows that you value their feedback and are committed to making things right, which can go a long way in turning a negative experience into a positive one.

ShipBob’s fulfillment network approach to maintaining delivery estimate accuracy

ShipBob’s distributed fulfillment network is designed to optimize delivery estimate accuracy by leveraging strategic warehouse placement, advanced technology integration, and real-time visibility. This approach differs from traditional single-warehouse models by bringing inventory closer to end customers, reducing transit times, and minimizing the risk of delays.

Strategic fulfillment center placement

At the heart of ShipBob’s approach is a network of strategically located fulfillment centers that enable ecommerce businesses to store inventory in close proximity to their customers. By analyzing factors such as historical sales data, ShipBob identifies the optimal placement for each merchant’s products to maximize delivery speed and accuracy.

This geographic distribution of inventory has a direct impact on delivery estimate accuracy. With shorter distances to travel and more efficient routing options, packages can be delivered more quickly and reliably than if they were shipped from a single, centralized warehouse. ShipBob’s algorithm also takes into account factors like carrier performance and capacity constraints in each region to ensure the most accurate estimates possible.

In the US, brands can leverage ShipBob’s Inventory Placement Program (IPP) to automate inventory distribution, placement, and replenishment.

Technology integration and real-time visibility

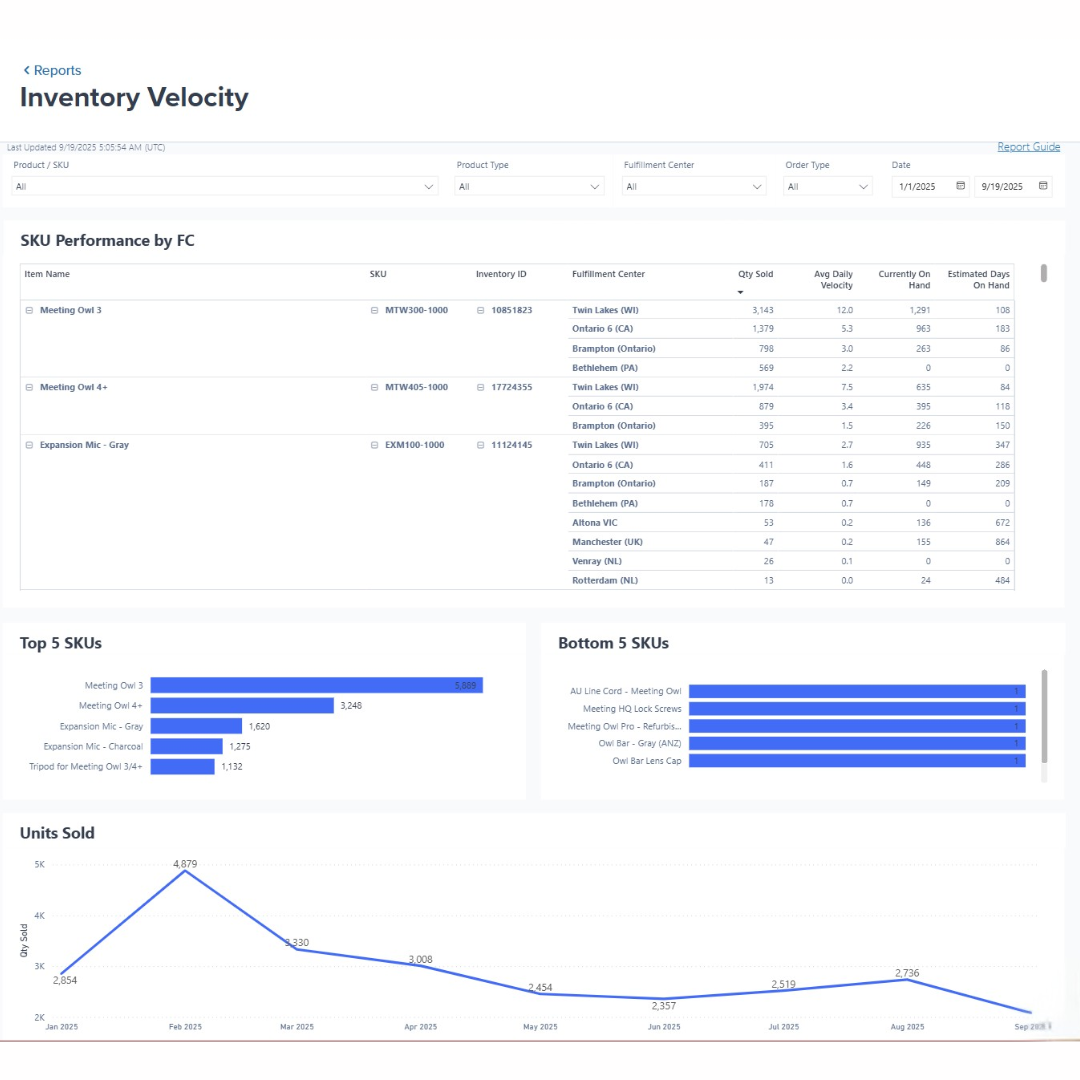

ShipBob’s fulfillment network is powered by advanced technology that enables real-time visibility and control over inventory levels, order routing, and delivery performance.

This real-time inventory visibility is critical for accurate delivery estimates, as it ensures that orders are only routed to locations with available stock. If a particular item is running low or out of stock at one warehouse, the system can automatically reroute the order to another location with inventory on hand, minimizing the risk of stockouts and backorders.

ShipBob’s technology also provides merchants with a centralized dashboard for monitoring and managing their fulfillment operations. This dashboard offers real-time insights into key metrics like order volume, inventory levels, and delivery performance, enabling businesses to make data-driven decisions and proactively address any issues that may impact delivery estimate accuracy.

Automated decision-making for optimal routing

Another key advantage of ShipBob’s fulfillment network is its ability to make automated, intelligent decisions about order routing and carrier selection. By analyzing real-time data on factors like inventory availability, carrier performance, and customer location, the system can dynamically route each order to the most efficient fulfillment center and shipping method.

This automated decision-making not only improves delivery speed and accuracy but also helps to optimize costs. For example, if a particular carrier is experiencing delays or capacity constraints in a certain region, the system can automatically select an alternative carrier with better performance metrics. This helps to ensure that delivery estimates are met while also minimizing shipping expenses.

In addition to optimizing carrier selection, ShipBob’s technology can also automatically upgrade shipping methods when necessary to meet delivery deadlines. If an order is at risk of missing its estimated delivery date due to unexpected delays, the system can proactively upgrade the shipping method to a faster option, helping to maintain the merchant’s promise to the customer.

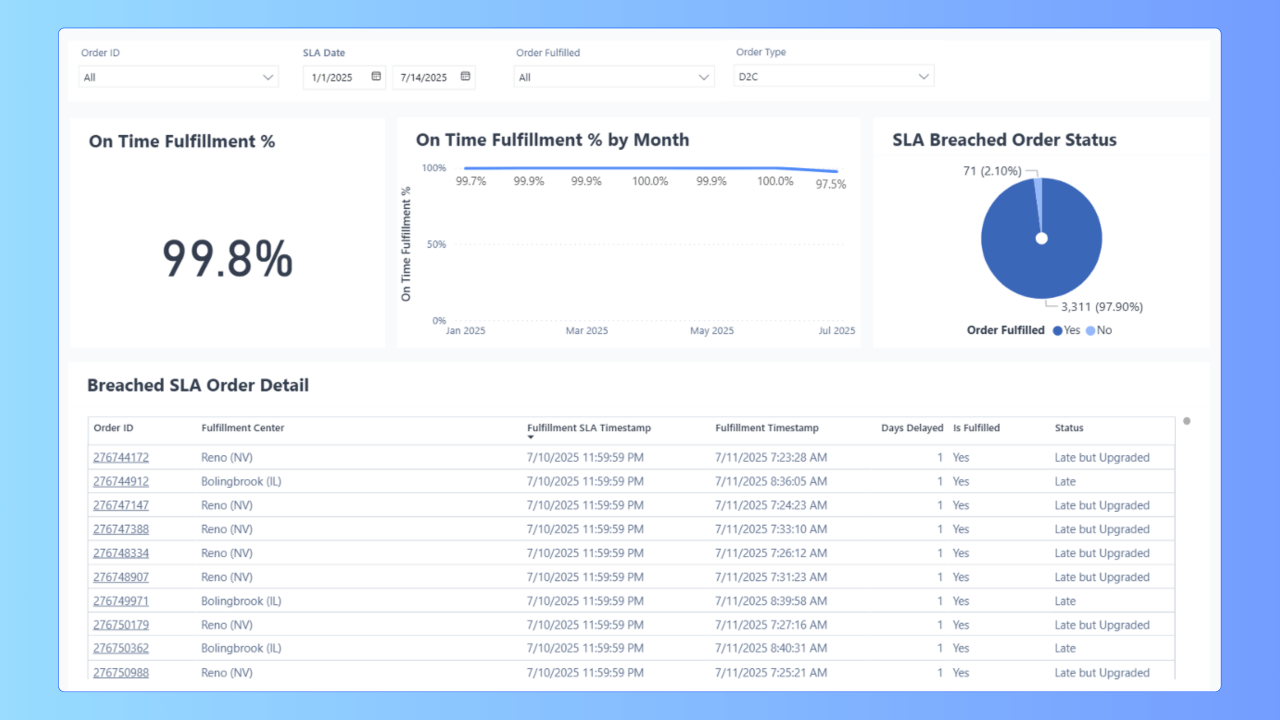

Real-time SLA tracking and visibility

To help merchants stay on top of their delivery performance, ShipBob provides real-time SLA tracking that monitors every order against its promised delivery date.

This at-a-glance visibility enables merchants to quickly identify and address potential issues before they impact the customer experience. By drilling down into the details of each order, businesses can see exactly where the order is in the fulfillment process, what carrier it has been assigned to, and what the current estimated delivery date is.

This level of transparency and control is especially valuable during peak seasons or periods of disruption, when delivery estimates may be more prone to fluctuation. By proactively monitoring SLAs and communicating any changes to customers, merchants can maintain trust and loyalty even in challenging circumstances.

Carrier performance optimization

ShipBob’s fulfillment network is designed to optimize carrier performance and reliability through strategic partnerships and data-driven decision-making. By leveraging the combined shipping volume of thousands of ecommerce businesses, ShipBob is able to negotiate favorable rates and service level agreements with major carriers like UPS, FedEx, and USPS.

This bargaining power not only helps to keep shipping costs down for merchants but also ensures that carriers are held accountable for meeting delivery estimates. ShipBob’s technology continuously monitors carrier performance data and adjusts routing decisions accordingly, prioritizing carriers with the best on-time delivery rates and lowest instances of delays or damage.

In addition to these strategic carrier relationships, ShipBob also employs a multi-carrier approach that enables merchants to diversify their shipping options and reduce reliance on any single provider. By automatically selecting the optimal carrier for each order based on real-time performance data, ShipBob helps to mitigate the risk of delays or disruptions caused by carrier-specific issues.

Get started with ShipBob

Provide an enhanced customer experience and gain deep, real-time analytics with ShipBob. Connect with our team to get started.

FAQs about delivery estimate accuracy

Below are answers to common queries and frequently encountered delivery estimate accuracy challenges.

How do I measure my current delivery estimate accuracy?

To calculate your delivery estimate accuracy, divide the number of orders delivered within the promised time window by the total number of orders shipped. For example, if you shipped 1,000 orders and 850 were delivered within the estimated timeframe, your DEA would be 85% (850 ÷ 1,000 = 0.85).

To gain deeper insights, segment your data by factors such as carrier, shipping method, product category, and destination region. This will help you identify specific areas for improvement. Benchmarking your performance against industry standards can provide context for your current level of accuracy and help you set realistic targets.

How can I improve my delivery estimate accuracy without extending timelines?

Improving delivery estimate accuracy doesn’t necessarily require padding your timelines. Start by optimizing your fulfillment operations to minimize processing times. This could involve streamlining your pick and pack workflows, implementing batch or wave picking, and ensuring your fulfillment center is properly staffed and trained.

Technology solutions can also help enhance your prediction capabilities. Intelligent order routing, real-time carrier data integration, and machine learning algorithms can all contribute to more precise estimates. By leveraging data to continuously refine your estimation models, you can improve accuracy without sacrificing speed.

How does ShipBob calculate delivery estimates?

ShipBob’s delivery estimates are generated through a proprietary algorithm that takes into account a wide range of data points and factors. These include the distance between the fulfillment center and the destination, the carrier and service level selected, the weight and dimensions of the package, and historical performance data for similar shipments.

ShipBob’s technology also leverages machine learning to continuously improve the accuracy of its predictions over time. By analyzing millions of data points across its global fulfillment network, ShipBob is able to identify patterns and adjust its estimates accordingly. This networked approach allows for greater precision than single-warehouse models.

What is a good benchmark for delivery estimate accuracy?

Industry benchmarks for DEA vary depending on the product category and customer expectations. For example, customers tend to be more forgiving of longer estimates for large or complex items, while they expect faster and more precise estimates for everyday essentials.

As a general rule, a DEA of 90% or higher is considered best-in-class for most ecommerce categories. However, some leading brands are able to consistently achieve 95%+ accuracy through a combination of strategic fulfillment models and advanced technology. The key is to set targets that are ambitious but achievable based on your specific business model and resources.

How does delivery estimate accuracy affect customer lifetime value?

Delivery estimate accuracy has a direct impact on customer lifetime value (CLV). Studies have shown that customers who receive their orders within the promised timeframe are more likely to make repeat purchases and recommend the brand to others. Conversely, missed delivery estimates can erode trust and lead to increased churn.

For example, 85% of consumers are unlikely to shop with a brand again after a poor last mile delivery experience. By improving DEA, brands can boost retention rates and drive higher CLV. To calculate the ROI of investing in DEA improvements, consider metrics such as repeat purchase rate, average order value, and customer acquisition costs. Even small gains in accuracy can lead to significant financial returns over time.