Verified & Reviewed

Published on October 6, 2025 Written By Rachel Hand

Published on October 6, 2025 Written By Rachel Hand

Subscribe for More

Today’s ecommerce landscape demands faster delivery, greater flexibility, and real-time visibility – and traditional, linear supply chains are struggling to keep up.

That’s where digital supply chain networks come in: interconnected ecosystems powered by advanced technologies that drive agility, collaboration, and operational excellence.

In this guide, we’ll break down what digital supply chain networks are, how they differ from legacy models, and the technologies fueling their rise. You’ll also learn how to transition your ecommerce supply chain into a digitized, data-driven powerhouse—with real-world strategies, tools, and insights to help you thrive in a new era.

What is a digital supply chain network?

A digital supply chain network is an interconnected digital ecosystem where all supply chain stakeholders share real-time data to optimize operations.

In a digital supply chain network, everyone works together and shares information in real time, instead of passing tasks along step by step or only reacting when problems arise. This kind of teamwork allows for faster, smarter decisions.

Each member of the network adds value and also benefits from the shared knowledge, tools, and resources available. This collaborative way of working helps companies stay innovative, flexible, and strong when facing new challenges.

Digital supply chain networks vs. management

Digital supply chain management focuses on the strategies and tools used to run and improve the supply chain. In contrast, a digital supply chain network is the bigger picture – the full system of connected partners, technologies, and data that allows everything to work smoothly from start to finish.

Key advantage: network effects

One big advantage of a digital supply chain network is something called “network effects.” This means that the more companies that join and share data, the more valuable and efficient the network becomes. Every additional node in the network adds to the overall knowledge and ability of the network to solve problems.

For example, imagine a network where manufacturers, suppliers, shipping companies, and retailers are all connected and sharing real-time information. If a supplier experiences a disruption, the network can instantly alert everyone who’s affected. Then, the group can work together to find a new supplier or adjust production plans. This kind of teamwork helps reduce delays and keeps everything running smoothly.

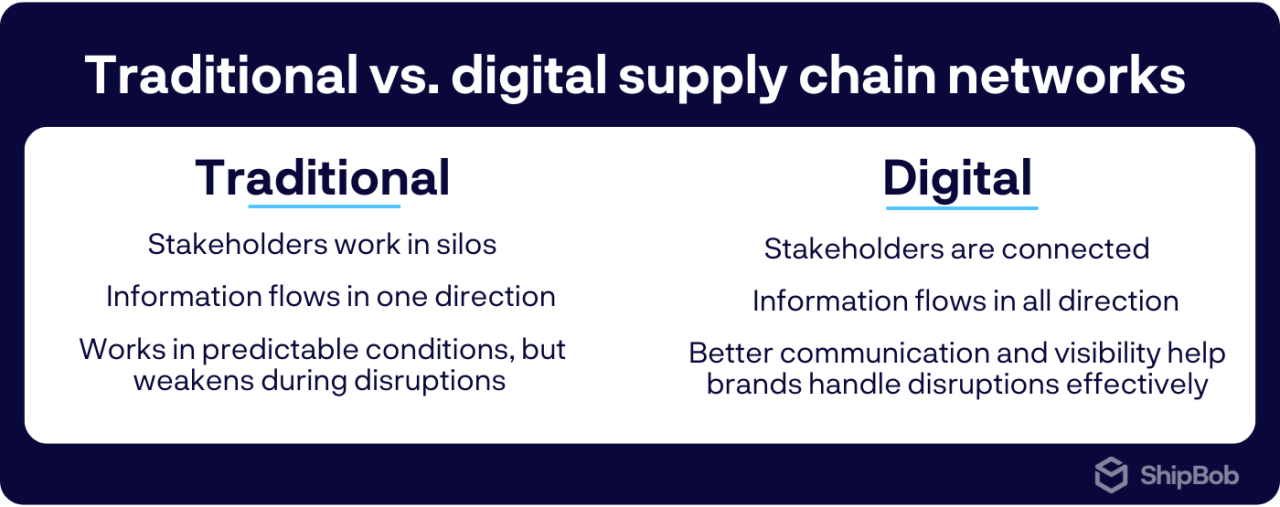

Traditional vs. digital supply chain networks

To understand the real power of digital supply chain networks, it helps to compare them to traditional supply chains.

In a traditional supply chain, each stage (supplier, manufacturer, distributor, and retailer) works mostly in isolation. Information flows in one direction, and each part of the chain makes decisions independently.

This approach was effective when demand was steady and supply was predictable. But today’s fast-moving, unpredictable business environment exposes its weaknesses. When disruptions like supply shortages, transportation delays, or unexpected demand spikes occur, each stage of the traditional supply chain reacts on its own. This often leads to delays, miscommunication, and lost sales because there’s limited visibility across the full chain.

A digital supply chain network, on the other hand, connects all stakeholders in real-time. Everyone shares data and collaborates to solve problems together. This creates a more agile and resilient system.

For example, if a major storm disrupts transport routes in a certain region, a traditional supply chain might see each company scrambling independently to reroute shipments. But in a digital network, the disruption is visible to everyone immediately. The system can suggest alternate routes, adjust inventory across locations, and even reroute deliveries automatically—reducing delays and avoiding extra costs.

This kind of visibility and speed is only possible when the entire supply chain is connected and working together. By removing silos and enabling real-time collaboration, digital supply chain networks create a smarter, more responsive system that can adapt quickly to any challenge.

5 core technologies powering digital supply chain networks

Digital supply chain networks are powered by a set of advanced technologies that work together to keep everything connected and running smoothly. These technologies enables real-time visibility, intelligent decision-making, and seamless collaboration among all stakeholders.

Let’s take a closer look at the five main technologies that are helping to modernize and improve how today’s supply chains operate.

AI and machine learning

Artificial Intelligence (AI) and machine learning are key tools in making digital supply chains work smarter and more efficiently. They can:

- Analyze huge amounts of data from different sources to spot patterns, predict what might happen next, and suggest the best actions to take.

- Improve demand forecasting, so brands can make sure they have the right amount of stock ready.

- Streamline inventory management across different locations and channels, making sure products are where they need to be when they’re needed.

- Automatically choose the best warehouse to ship from, based on stock levels, shipping costs, and how fast the order needs to arrive.

- Spot unusual activity or potential problems early, giving businesses a chance to fix issues before they turn into bigger disruptions.

The internet of things (IoT)

The Internet of Things (IoT) is a network of connected devices that collect and transmit data without human intervention.

In digital supply chains, IoT devices give real-time updates on what’s happening at every stage. For example, sensors can track inventory levels in different warehouses, so businesses always know how much stock they have and where it’s moving.

This is especially useful for companies that handle sensitive products—like food or medicine—because IoT devices can also monitor things like temperature and humidity to make sure the products stay safe and in good condition.

In transportation, IoT sensors help with predictive maintenance by spotting potential issues in trucks or machines before they break down. This helps avoid delays and keeps everything running smoothly. IoT also improves last-mile delivery by offering real-time tracking and adjusting delivery routes on the fly based on traffic or customer needs.

Blockchain for secure data sharing

Blockchain technology is changing the way data is shared in digital supply chains. It works like a secure, digital record book that can’t be changed, helping ensure that all data is accurate and trustworthy.

In a supply chain, the blockchain:

- Lets multiple partners share information in a way that’s secure and tamper-proof, building trust and transparency across the network.

- Can be used to track a product’s entire journey, from raw materials all the way to the customer, so companies can confirm where it came from and that it’s authentic.

- Supports smart contracts, which are agreements written in code that automatically carry out tasks like payments or shipments when certain conditions are met. This helps reduce delays, mistakes, and disagreements between partners.

While setting up blockchain can seem complicated at first, the long-term benefits of safe, transparent data sharing make it well worth the effort.

Cloud-based platforms and integrations

Cloud-based platforms serve as the backbone of digital supply chain networks. They act as a central place to store data, process information, and help everyone work together easily.

Using the cloud, businesses can access their supply chain information anytime and from anywhere, making it easier to respond quickly and stay flexible. Cloud platforms also connect different systems – like enterprise resource planning systems (ERP), warehouse management systems (WMS), and transportation management systems (TMS) – so all the data is combined in one place. This integration allows for a unified view of the entire supply chain, breaking down data silos and enabling end-to-end visibility.

Another big benefit is that cloud solutions are inherently scalable, so they can easily grow with the business without requiring expensive new equipment. Plus, since cloud providers keep updating their services, companies always get the latest features and security improvements without any interruptions.

Real-time analytics and control towers

Real-time analytics and supply chain control towers act like the command centers of digital supply chains. Control towers gather data from everyone involved in the supply chain and give a complete, up-to-date picture of what’s happening.

With real-time analytics, control towers help spot problems before they get worse and suggest ways to fix them. They also let businesses try out different “what-if” scenarios to find the best plan for their supply chain.

Control towers can even automatically respond to issues, like changing delivery routes or adjusting production schedules, to keep things running smoothly and reduce the impact on customers.

They also make it easier to track how well the entire supply chain is performing, so businesses can make smarter decisions, especially during busy times or unexpected delays.

How to transition from a traditional supply chain to a digital supply chain network

Making the leap from a traditional, linear supply chain to a fully connected digital network may seem daunting, but it’s much easier when you have the right strategy. The key to a smooth handoff is to transition gradually, taking small steps that deliver tangible benefits along the way.

Here are 5 key steps to follow to seamlessly transition your brand to a digital supply chain network.

1. Define goals and secure stakeholder alignment

Before you begin the transition, take some time to outline what you want to gain from transitioning to a digital supply chain network. This can include:

- Operational efficiency improvements

- More streamlined communication between stakeholders

- Cost-savings and/or time-savings

- Increased scalability across locations and channels

- Better visibility into supply chain operations and performance

Getting buy-in from both internal teams and external partners is essential for a successful transition. To convince others:

- Focus on showing how digital projects will save money, improve efficiency, and create a better experience for customers.

- Involve important people early on and highlight how a digital supply chain can give the company an edge over competitors.

- Find leaders who can champion the effort and help gather the resources and backing needed.

- Encourage a culture where everyone works together openly, sharing ideas and feedback across teams and partners.

2. Plan technology adoption and integrations

With goals defined and stakeholders on board, your next step is to assess your current supply chain technology landscape and identify what software or platform integrations you’ll need. To do this, make sure you:

- Evaluate potential solutions based on their ability to connect disparate systems, provide real-time visibility, and support data-driven decision making.

- Consider starting with high-impact, lower-complexity implementations that can deliver quick wins.

- Select tools that integrate seamlessly with your existing tech stack, prioritizing platforms like Shopify or Amazon that are key to orderworkflows and data exchange.

- Look for solutions that offer pre-built integrations to minimize custom development efforts and accelerate time-to-value.

3. Manage organizational change

As you start your digital transformation, don’t overlook the importance of change management.

- Make sure everyone understands the vision and benefits of the shift by communicating clearly and regularly.

- Show how the changes will make their work easier and more valuable.

- Offer training and support to help teams get comfortable with new tools and processes, and consider appointing “digital champions” in each department to encourage adoption.

Remember: a digital supply chain might require new skills and roles, like data analysts, integration experts, and automation specialists. Take a look at your current team to see if there are any skill gaps, and plan to fill them through training, hiring, or partnerships.

4. Address cybersecurity and data protection

As supply chains become more connected, they also become more vulnerable to cyber threats. That’s why cybersecurity is a very important part of any digital supply chain project. Start by carefully identifying possible risks and weak points, then put strong security measures in place to protect sensitive data (whether it’s being shared or stored).

When working with external partners, establish clear data governance frameworks that define roles, responsibilities, and access controls. Regularly check and update your security practices and conduct periodic audits to identify and address any weaknesses. By prioritizing data protection from the outset, you can build trust and confidence among all network participants.

5. Measure success and refine processes

As you roll out digital changes, it’s important to measure your progress using clear goals and key performance indicators (KPIs).

Set up a tracking system or find a dashboard that gives you visibility into includes metrics like inventory accuracy, order processing time, on-time delivery rates, and how well you’re forecasting demand. These numbers will help you see what’s working, what needs improvement, and how your digital efforts are paying off.

Keep in mind that digital transformation isn’t a one-time project; it’s an ongoing process. Use data and analytics to regularly review your operations, spot areas for improvement, and make smarter decisions.

Switching to a digital supply chain can be challenging, but the benefits – faster operations, greater flexibility, and happier customers – make it worth the effort. By taking a thoughtful, step-by-step approach and using the right technology and partners, ecommerce brands can set themselves up for long-term success in the modern, tech-driven business world.

The future of digital supply chain networks and Industry 4.0

As digital supply chain networks continue to evolve, the principles of Industry 4.0 are poised to further enhance their capabilities. Industry 4.0, characterized by the convergence of advanced technologies like artificial intelligence, the Internet of Things, and automation, is creating more responsive, resilient, and intelligent supply chains.

While some of these technologies may seem futuristic, many are already being implemented by forward-thinking organizations. As costs decrease and capabilities expand, we can expect widespread adoption in the coming years.

Let’s explore some of the most promising advancements and their potential impact on digital supply chain networks.

Digital twins for supply chain optimization

Digital twins are virtual models of your real-world supply chain, including everything from processes and equipment to entire networks. They let you test ideas and make improvements in a virtual environment without affecting actual operations.

For example, you can use a digital twin to try out different ways of organizing your warehouses and inventory to see what setup works best. You can also simulate problems (such as a sudden surge in customer demand or a supplier going offline) and test different ways to respond, so you’re better prepared if those things happen in real life.

Additive manufacturing and customization

Additive manufacturing, also known as 3D printing, is changing how products are designed, made, and delivered – especially for ecommerce brands. It allows companies to produce items on demand, which means they don’t need to keep large amounts of stock sitting in warehouses.

With 3D printing, businesses can make products, tools, or parts only when they’re needed. This helps save money on storage, speeds up product development, and makes it easier to quickly respond to changes in customer demand.

It also makes personalization much more affordable. Ecommerce brands can offer customized products without the high costs that used to come with special orders, giving them a competitive edge.

As 3D printing technology keeps improving and becomes more affordable, we’ll likely see more local production, with small manufacturing centers set up closer to customers. This can cut shipping costs and delivery times while also supporting more sustainable supply chains.

Collaboration and measurable outcomes

One of the biggest advantages of digital supply chain networks is that they make it easier for companies to work more closely with their partners. By sharing data and insights in real time, everyone involved can coordinate better, improve efficiency, and make smarter decisions together.

This kind of teamwork can take many forms, like joint planning for demand and inventory, sharing production capacity, or even co-developing new products. For example, a retailer and its suppliers could use a shared system to match production schedules with expected customer demand, helping avoid having too much or too little stock.

Sustainability is another area where working together matters. Digital supply chain networks can support joint efforts to reduce waste, improve delivery routes, and track whether suppliers are meeting environmental standards.

How ShipBob unifies your digital supply chain network

As an ecommerce brand navigating the complexities of digital supply chain networks, partnering with a trusted logistics provider or 3PL like ShipBob can make all the difference. ShipBob’s technology platform and global fulfillment network are designed to unify your supply chain, providing the visibility, flexibility, and scalability you need to thrive in the Industry 4.0 era.

Seamless integrations with ecommerce platforms

ShipBob offers native integrations with all major ecommerce platforms, including Shopify, WooCommerce, Amazon, and more. These seamless integrations automate order workflows and data exchange, eliminating the need for manual data entry and reducing the risk of errors.

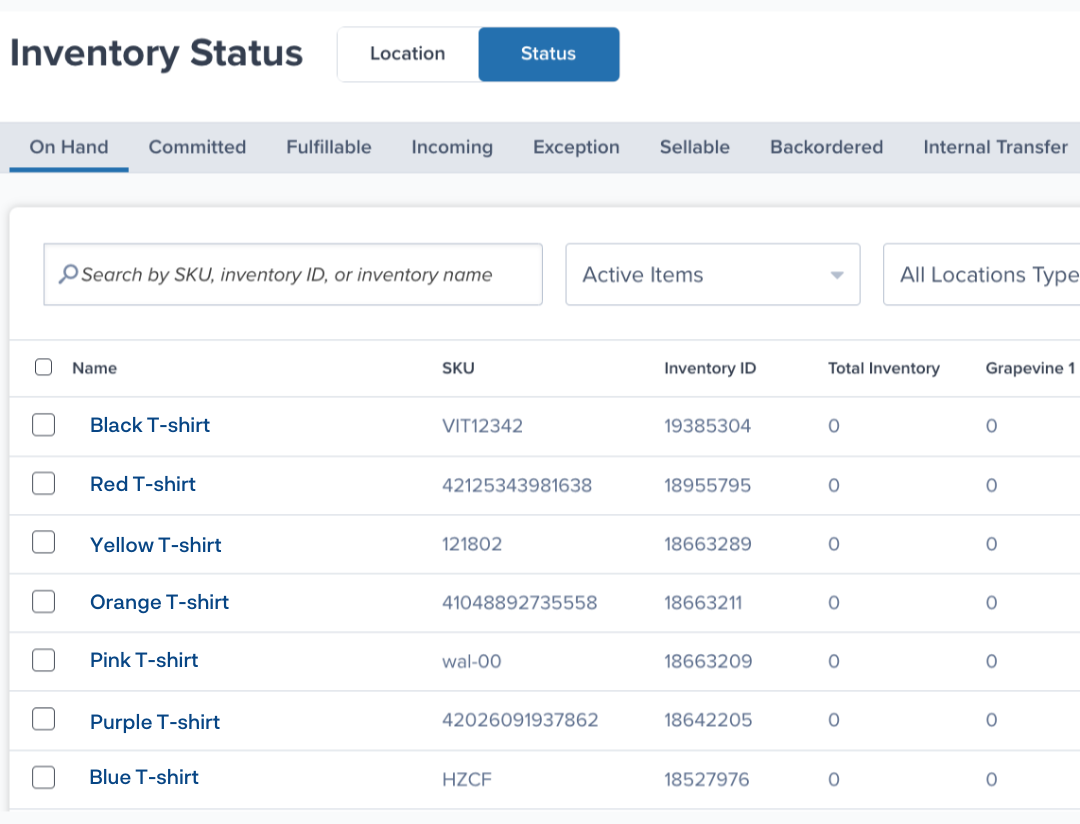

With ShipBob’s connected systems, you can enjoy real-time inventory updates across all your sales channels, ensuring that your customers always have access to accurate stock information. Orders are automatically routed to the optimal fulfillment center based on factors like inventory availability and shipping destination, streamlining the fulfillment process.

Moreover, ShipBob’s integrations enable synchronized customer communications, with automated shipping notifications and tracking updates sent directly to your customers. This level of integration creates a unified data ecosystem, giving you a single source of truth for all your supply chain operations.

“One of the biggest surprises with ShipBob is the number of integrations we’ve been able to use. We’ve been able to improve our omnichannel experience as a result of our partnership. For example, we’re fulfilling our TikTok Shop orders through ShipBob, which we’ve been able to greatly increase. And the fulfillment times are incredible. 98% of our TikTok Shop orders are being fulfilled on the same day they are placed.”

Jessica Stoller, Director of Supply Chain and Operations at Arrae

Advanced analytics and forecasting

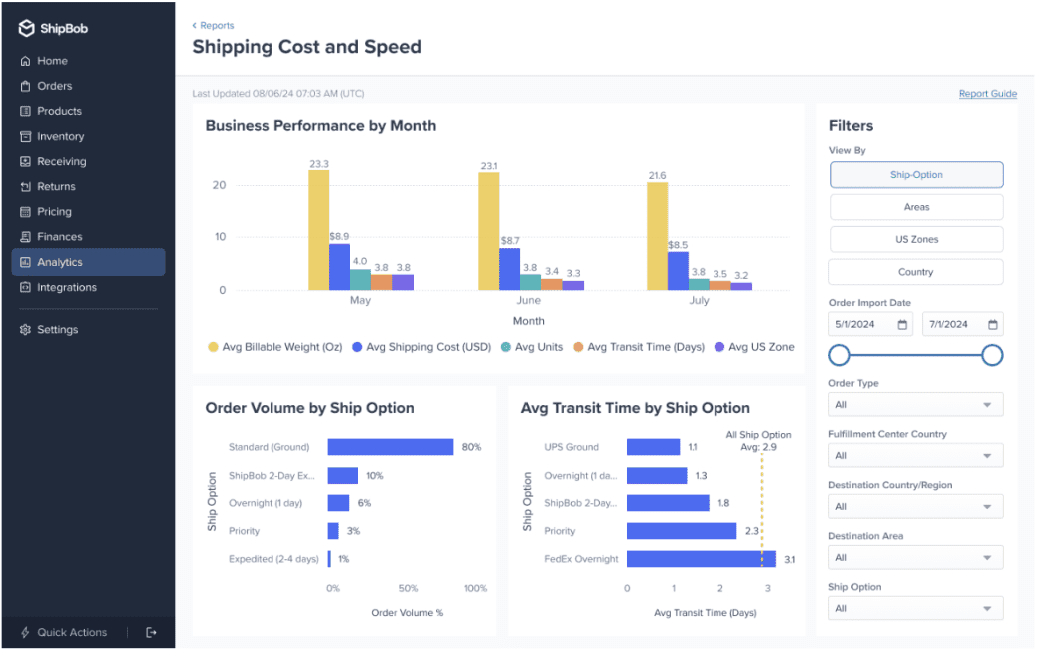

ShipBob’s advanced analytics tools provide actionable insights to help you optimize your supply chain performance. With demand forecasting and trend identification capabilities, you can proactively plan for future growth and ensure that you have the right inventory in the right places at the right times.

Inventory optimization recommendations help you strike the perfect balance between availability and carrying costs, while fulfillment performance metrics give you visibility into key indicators like order accuracy and on-time delivery rates. ShipBob’s shipping cost analysis tools enable you to identify opportunities for cost savings and make data-driven decisions about your transportation strategies.

By leveraging these analytics capabilities, you can gain a comprehensive view of your supply chain performance and make informed decisions to drive continuous improvement. ShipBob’s data-driven insights help you optimize your entire supply chain, from demand planning to last-mile delivery.

“One of my favorite parts of ShipBob’s solution is the analytics I get through the ShipBob dashboard. I use the reporting constantly, especially to track my stock. It’s even helping me get better at inventory forecasting. Before, I was just fumbling through the demand planning process and just ordering inventory based on what sold out. But now I have insight into metrics like SKU velocity and inventory days on hand, and I’m using that to decide what to reorder and how much of it I need. That helps a lot, especially now that the brand is scaling and I’m ordering my products in bigger batches.”

Luke Rolls, Founder of The Protein Pancake

Global fulfillment network

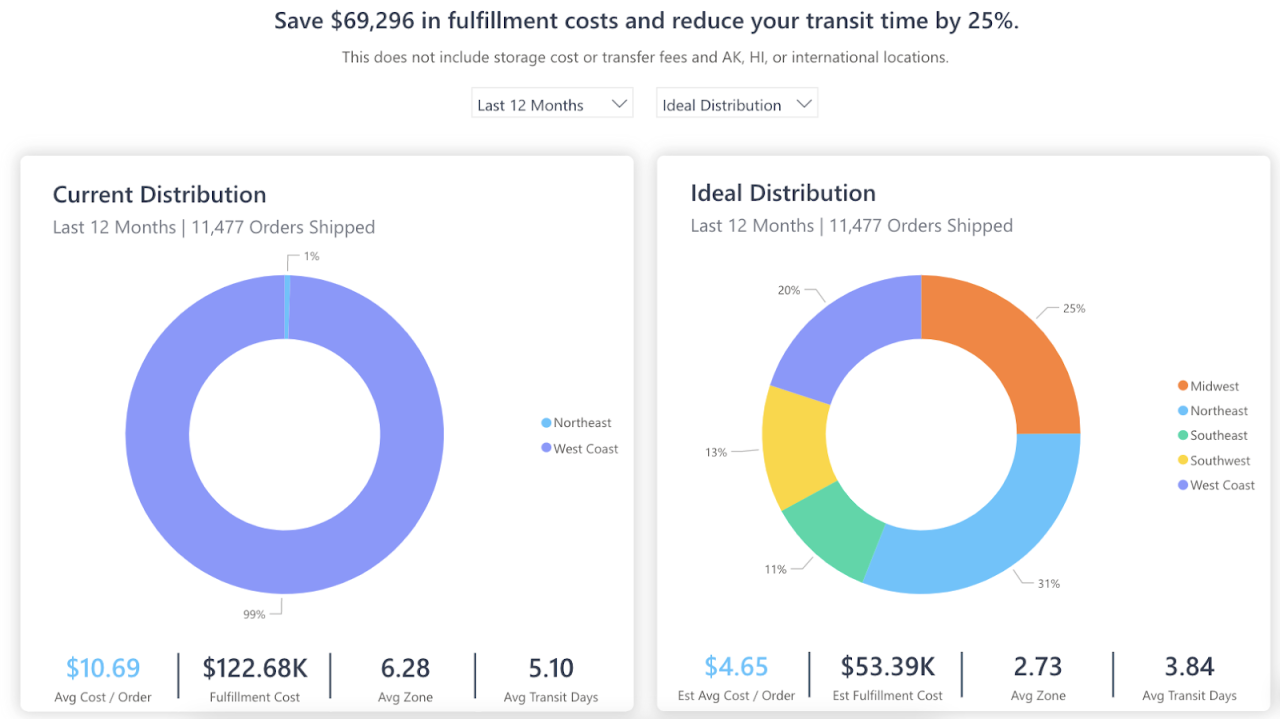

With dozens of fulfillment centers across six countries, ShipBob’s global network is designed to scale with your business. This extensive physical infrastructure is digitally connected through ShipBob’s proprietary software, creating a unified and agile fulfillment ecosystem.

By distributing your inventory across multiple fulfillment centers, you can position your products closer to your customers, reducing shipping times and costs. ShipBob’s technology calculates the idea inventory allocation strategy across our network to optimize your shipping costs and transit times, and automatically routes each order to the optimal fulfillment center based on factors like inventory availability and shipping destination to ensure that your customers receive their orders as quickly and cost-effectively as possible.

ShipBob’s global network also provides built-in redundancy and business continuity, protecting your operations from disruptions caused by weather events, transportation delays, or other unforeseen circumstances. If one fulfillment center is impacted, orders can be seamlessly rerouted to another location, minimizing any potential impact on your customers.

For brands looking to expand internationally, ShipBob’s global footprint simplifies the complexities of cross-border logistics. By leveraging ShipBob’s network, you can enter new markets without the need to establish your own infrastructure, reducing costs and accelerating your time to market.

“We’re constantly looking at expanding into different markets, so working with a global fulfillment partner was a factor in our decision. While we’re currently only fulfilling orders from the UK, we know that with ShipBob as our partner, we could seamlessly place inventory in new countries and keep everything within the ShipBob platform. If we wanted to start storing products in the US or mainland Europe, we would have a direct connection there because of ShipBob, while allowing us to keep everything within one ecosystem. This is really important as we scale our operations and supply chain.”

Connor Stewart, Head of Operations + Impact at ARTAH

For more on how ShipBob can help your brand digitize and master ecommerce suply chain and logistics, click the button below to get in touch.

Digital supply chain network FAQs

Here are answers to some of the most common questions about digital supply chain networks.

What’s the difference between a digital supply chain network and digital supply chain management?

Think of it this way: the digital supply chain network is like the internet, while digital supply chain management is how you use that internet to communicate, transact, and grow your business.

A digital supply chain network refers to the interconnected ecosystem of partners sharing data in real-time to optimize operations. It’s the infrastructure that enables seamless collaboration and information flow across the entire supply chain.

On the other hand, digital supply chain management encompasses the strategies, processes, and tools used within that network to effectively navigate and control the flow of goods, information, and finances. It’s how you leverage the network infrastructure to achieve your business objectives.

How do I ensure data security and privacy across partners in a digital supply chain?

Ensuring data security and privacy across multiple partners in a digital supply chain network is crucial. Start by implementing role-based access controls for shared data, so each partner only has access to the information they need to perform their function.

Establish clear data governance policies with all partners, outlining who owns what data, how it can be used, and how it should be protected. Regular security audits and vulnerability assessments help identify and address potential weaknesses in your network.

Finally, always encrypt sensitive data both in transit and at rest to prevent unauthorized access. By taking a proactive, multi-layered approach to security, you can protect your business and your partners in a connected digital ecosystem.

What are the cost-saving benefits of adopting a digital supply chain network?

Adopting a digital supply chain network can drive significant cost savings across your operations. With real-time visibility into inventory levels and demand patterns, you can optimize stock levels and reduce carrying costs.

Intelligent routing and transportation management tools minimize shipping expenses, while automation streamlines processes and reduces labor costs. By preventing stockouts and overstocking situations, you avoid lost sales and unnecessary holding costs.

How can ShipBob help me get started with a digital supply chain network?

ShipBob is your partner in creating a unified digital supply chain network. As a full-service logistics provider, we offer both the physical infrastructure and the digital tools you need to optimize your supply chain. Start with our core fulfillment services, and then expand into inventory management, order analytics, and more.

Our team of experts will guide you through the process of connecting you with key partners like carriers and suppliers to build a resilient, responsive network. With ShipBob, you can focus on growing your business while we handle the complexities of your digital supply chain transformation.

What metrics should I track to measure the success of my digital supply chain network?

To gauge the effectiveness of your digital supply chain network, track key performance indicators (KPIs) that align with your business goals. The perfect order rate, which measures complete, accurate, and on-time deliveries, is a critical metric for customer satisfaction.

Monitor your order cycle time, from placement to delivery, to identify opportunities for improvement. Keep a close eye on inventory turnover and carrying costs to optimize your stock levels and minimize expenses.

A supply chain visibility index can help you assess the transparency and accessibility of data across your network. Finally, track your total supply chain costs as a percentage of revenue to ensure your operations remain efficient and profitable.