Verified & Reviewed

Published on July 17, 2025 Written By Meredith Flora

Published on July 17, 2025 Written By Meredith Flora

Subscribe for More

Global supply chains face unprecedented challenges today, hitting ecommerce businesses with delayed shipments, higher costs, inventory problems, and unhappy customers.

This guide analyzes supply chain challenges across ecommerce sectors, highlighting critical obstacles and providing expert forecasts to help you plan ahead.

We’ll share seven actionable strategies to strengthen your supply chain: diversifying suppliers, tracking inventory in real-time, distributing fulfillment strategically, addressing workforce gaps, and maintaining transparent customer communication.

What are the largest supply chain issues in today’s market?

Supply chain disruptions plague today’s ecommerce landscape, hitting online retailers with delayed shipments, higher costs, inventory shortages, and unhappy customers—all directly impacting profits.

These disruptions are unexpected events that block the smooth flow of goods from suppliers to consumers. Some are temporary, like weather-related delays, while others are systemic, affecting global supply chains for extended periods.

Systemic issues create the biggest challenges for ecommerce brands because they stem from complex factors beyond a company’s control. Trade disputes and regional conflicts can trigger tariffs and restrictions that halt cross-border product movement. Meanwhile, transportation and warehouse labor shortages create bottlenecks that extend delivery times and drive up costs.

For ecommerce success, retailers must distinguish between temporary disruptions and long-term systemic problems. This understanding helps brands create strategies that reduce risk, maintain efficiency, and deliver excellent customer experiences despite supply chain challenges.

The current state of global supply chain issues

In 2025, global supply chains face ongoing challenges across all ecommerce sectors. Geopolitical issues disrupt international trade, labor shortages in transportation and warehousing create supply chain bottlenecks between manufacturers and consumers, and COVID-19’s lingering effects still impact manufacturing.

Meanwhile, changing tariffs and import/export regulations add another layer of complexity for businesses trying to navigate the shifting trade landscape.

The impact of these supply chain issues varies across different ecommerce sectors, each facing its own unique set of challenges:

- Electronics: Severe semiconductor shortages have led to production delays and limited availability of critical components, resulting in longer lead times for popular consumer electronics. Some brands are exploring alternative sourcing options as a result.

- Apparel: Fabric production and sourcing challenges have been a challenge for the apparel sector, with many brands struggling to maintain consistent inventory levels. Labor shortages in key manufacturing hubs have further exacerbated these issues, leading to delays in product launches and stockouts of popular items.

- Beauty and cosmetics: Shortages of packaging material like glass and plastic have hindered the production and distribution of cosmetic products. As a result, brands have had to find alternative packaging solutions or adjust their products to accommodate available materials.

- Food and beverage: The food and beverage sector has been impacted by ingredient availability issues and disruptions to cold chain logistics. This has led to shortages of certain products and has forced some brands to reformulate their offerings or to explore alternative sourcing options.

Across all sectors, ecommerce brands are grappling with operational challenges in the current supply chain environment. Container shortages, port congestion, and limited equipment availability have slowed the movement of goods and have driven up transportation costs. This has put pressure on brands to optimize their supply chain strategies and to explore alternative fulfillment options to ensure timely delivery to their customers.

To navigate this complex and ever-evolving landscape, it is crucial to remain agile and adaptable. By staying informed about the latest supply chain developments and implementing strategies to mitigate disruptions, brands can weather the challenges ahead and emerge stronger for it.

Where do these supply chain issues come from (and how long might they last?)

The current global supply chain disruptions have been building since the onset of the COVID-19 pandemic in early 2020.

As countries worldwide implemented lockdowns, manufacturing facilities and ports experienced sudden closures, leading to a cascading effect of shipping delays and bottlenecks. Even as economies began to reopen, the supply chain struggled to keep pace with pent-up consumer demand, resulting in shortages and increased costs.

Many of these issues persist today, compounded by new geopolitical tensions and ongoing labor shortages. The Russia-Ukraine conflict, for example, has disrupted key manufacturing sectors, while tensions between China and the US continue to impact trade flows.

Simultaneously, the logistics industry faces a chronic shortage of workers, further exacerbating delays and capacity constraints.

Expert forecasts for supply chain recovery

As for how long these disruptions might last, expert opinions vary. Some analysts predict a gradual easing of pressures throughout 2025 as businesses adapt and invest in more resilient supply chain strategies. Others caution that sectors such as electronics and semiconductors may face longer recovery timelines due to the complexity of their global production networks.

Preparing for continued uncertainty

One thing is clear: waiting for a complete return to pre-pandemic supply chain conditions may not be a realistic strategy.

Dr. Madhav Durbha, VP of Supply Chain Strategy at Coupa Software, emphasized that building resilience requires a change in mindset, executive support, cross-functional collaboration, and investment in technology. This approach enables organizations to make rapid decisions, balancing costs, risks, and continuity in a volatile environment.

Ecommerce brands that proactively adapt to this new reality will be better positioned to weather future challenges and maintain a competitive edge. By investing in real-time visibility tools, exploring nearshoring options, and partnering with experienced logistics providers like ShipBob, online retailers can navigate the complexities of today’s global supply chain landscape with greater confidence and control.

How supply chain issues impact ecommerce businesses

Supply chain disruptions hit ecommerce businesses hard across multiple fronts. Rising transportation costs from fuel increases, container shortages, and port congestion squeeze profit margins as retailers absorb these expenses. When manufacturers face material shortages or delays, restocking popular items can take weeks or months, leading to lost sales and stockouts, which are especially devastating during peak seasons.

The impact of business size on supply chain resilience

The size of an ecommerce business can play a significant role in its ability to weather supply chain disruptions. Larger enterprise retailers often have more resources and leverage to mitigate the impact of these issues. They may have the financial capacity to secure alternative suppliers, invest in advanced technology solutions, or absorb short-term losses without jeopardizing their overall stability.

On the other hand, growing DTC brands may face greater challenges when confronted with supply chain disruptions. These businesses often operate on tighter margins and may not have the infrastructure and expertise to quickly adapt to changing circumstances, making them vulnerable to supply chain issues. To combat this, SMBs can partner with a logistics provider like ShipBob to help navigate supply chain complexities.

Maintaining transparency while navigating challenges

Maintaining transparency with customers is crucial to building and maintaining trust.

Proactively communicating about potential delays, updating product availability information, and setting realistic expectations can go a long way in preserving customer loyalty. By being honest about the challenges they face and the steps they are taking to address them, ecommerce businesses can demonstrate their commitment to providing the best possible experience, even in the face of adversity.

7 key strategies to mitigate supply chain issues

After examining recent supply chain disruptions, we’ve identified seven practical strategies to help ecommerce businesses build resilience and maintain operations during uncertain times.

1. Diversify suppliers and sourcing locations

Relying on a single supplier or sourcing location can leave your ecommerce business vulnerable to supply chain disruptions. Diversifying your supplier base is crucial for mitigating risks associated with geopolitical tensions, tariff changes, and regional instability.

To effectively diversify your suppliers:

- Identify potential risks in your current supply chain.

- Evaluate your dependency on specific regions or vendors, and assess the potential impact of disruptions in those areas.

- Begin researching and vetting alternative suppliers that can provide similar products or materials at competitive prices.

When considering new suppliers, it’s essential to balance cost, quality, and reliability. While it may be tempting to prioritize cost savings, working with suppliers who have a proven track record of consistency and dependability can help you avoid costly delays and quality issues down the line.

Another key consideration in supplier diversification is the choice between nearshoring and offshoring. Nearshoring involves working with suppliers in closer proximity to your target market, which can help reduce transportation costs and lead times. Offshoring, on the other hand, may offer lower production costs but can also introduce additional risks related to longer shipping distances and potential tariff changes.

2. Invest in technology for real-time inventory visibility

In the face of supply chain disruptions, having real-time visibility into your inventory levels and movements is essential for making informed decisions and adapting quickly to changing circumstances. Investing in advanced inventory management systems and demand forecasting tools can help you stay ahead of potential shortages and optimize your stock levels across multiple channels.

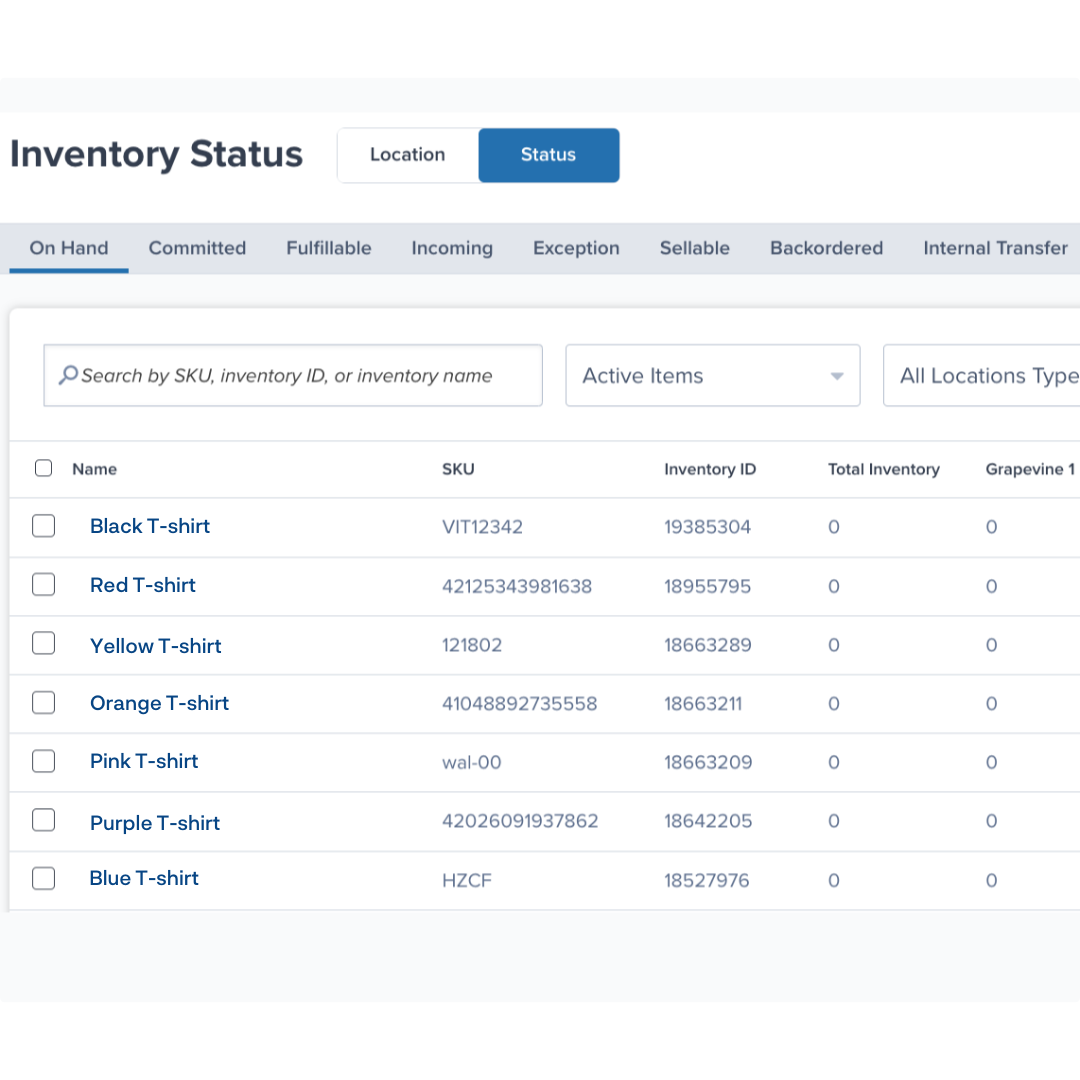

Look for inventory management solutions that provide a centralized, real-time view of your stock across all locations, including retail stores, warehouses, and fulfillment centers. These systems should also offer robust integration capabilities, allowing you to seamlessly connect your inventory data with your ecommerce platform, ERP system, and other key business applications. By maintaining a single source of truth for your inventory, you can avoid overselling, reduce manual errors, and make more accurate demand projections.

ShipBob’s proprietary software and cloud-based dashboard provides ecommerce businesses with real-time inventory insights across all fulfillment locations. With features like automatic reorder point notifications, detailed reporting, and advanced analytics, ShipBob empowers brands to make data-driven decisions and proactively manage their inventory in the face of supply chain uncertainties.

3. Implement a distributed fulfillment strategy

One of the most effective ways to build resilience into your ecommerce supply chain is by implementing a distributed fulfillment strategy. This approach involves strategically placing your inventory across multiple warehouses or fulfillment centers, located in different geographic regions.

By distributing your stock closer to your end customers, you can reduce shipping distances and transit times, which is particularly crucial during periods of supply chain disruption. Additionally, having inventory in multiple locations provides built-in redundancy, ensuring that you can continue to fulfill orders even if one facility experiences a temporary closure or reduced capacity.

To determine the optimal inventory distribution for your business, analyze your sales data and customer location information. Identify the regions where you have the highest concentration of customers, and consider placing inventory in fulfillment centers that can efficiently serve those areas. Keep in mind factors like shipping costs, tax implications, and potential tariff exposure when selecting your fulfillment locations.

ShipBob’s global network of 60+ fulfillment centers enables ecommerce businesses to easily distribute inventory. By leveraging ShipBob’s technology and infrastructure, brands can intelligently allocate their inventory across multiple facilities, reducing shipping costs and improving delivery speed for their customers.

4. Address labor shortages

The ecommerce industry has been grappling with significant labor and talent shortages, which can exacerbate supply chain disruptions, leading to delays in order processing, packaging, and shipping.

To address these challenges, ecommerce businesses need to develop proactive strategies for attracting and retaining skilled workers. This may involve offering competitive wages and benefits, providing opportunities for career advancement, and fostering a positive work environment.

In addition to traditional recruiting efforts, consider exploring automation technologies like robotics, conveyor systems, and automated storage and retrieval solutions can streamline warehouse operations, increase efficiency, and minimize the impact of labor shortages.

Another option for mitigating internal staffing challenges is partnering with a third-party logistics provider (3PL) like ShipBob. By outsourcing your fulfillment operations to a fulfillment provider, you can tap into their existing workforce and expertise, allowing you to scale your operations more easily without the need for significant in-house hiring.

5. Integrate sustainability into supply chain planning

As consumers become increasingly conscious of the environmental impact of their purchasing decisions, integrating sustainability into your supply chain planning is imperative. By adopting sustainable practices, you can reduce your carbon footprint, enhance your brand reputation, and build supply chain resilience.

Start by evaluating your current packaging and shipping materials. Look for opportunities to switch to eco-friendly alternatives, such as biodegradable or recyclable packaging, and consider optimizing your box sizes to minimize waste. You can also explore options for consolidated shipping, which reduces the number of individual packages sent out and lowers your overall transportation emissions.

When selecting suppliers and logistics partners, prioritize those that have a demonstrated commitment to sustainability. Look for companies that use renewable energy sources, implement waste reduction initiatives, and have a track record of environmental responsibility.

6. Communicate transparently with customers

During periods of supply chain disruption, proactively address potential delays or inventory shortages to manage customer expectations and minimize frustration.

Develop a clear communication strategy that leverages multiple channels, such as website banners, email notifications, and order status pages. Be upfront about any anticipated delays and provide realistic estimates for when customers can expect their orders to arrive. If you’re experiencing inventory shortages, consider offering alternative product recommendations or the option to pre-order items that will be restocked in the future.

7. Plan for seasonality and demand spikes

Effective supply chain management requires proactive planning for seasonal fluctuations and potential demand spikes. By anticipating these changes in advance, you can take steps to ensure that your inventory levels and fulfillment operations are prepared to handle increased volume.

Start by analyzing your historical sales data to identify seasonal patterns and peak periods. Use this information to create demand forecasts that account for potential supply chain bottlenecks and longer lead times. Consider implementing a buffer inventory strategy, which involves maintaining slightly higher stock levels than usual to accommodate unexpected surges in demand or delays in replenishment.

As you plan for peak seasons, it’s also essential to develop a flexible capacity plan for your fulfillment operations. This may involve hiring additional temporary staff, adopting a warehouse management software, or partnering with a 3PL that can provide scalable storage and fulfillment solutions.

Finally, create contingency plans for various scenarios that could affect your supply chain during peak seasons, such as identifying backup suppliers, exploring alternative shipping methods, or developing customer communication strategies. By proactively preparing for potential challenges, you can respond more quickly and effectively when disruptions occur.

How partnering with a global 3PL like ShipBob helps overcome supply chain challenges

Working with an established third-party logistics provider like ShipBob gives ecommerce brands immediate access to infrastructure and expertise that would take years to build internally.

Distributed fulfillment network for regional disruptions

ShipBob’s network of 60+ global facilities safeguards your business against disruptions by distributing inventory strategically. When disasters or congestion affect one area, orders automatically reroute to other locations without interruption.

Additionally, our cross-border fulfillment expertise handles customs documentation, duty calculations, and international shipping optimization, helping you navigate complex trade regulations and tariff changes without needing specialized in-house knowledge.

Real-time inventory management system for proactive decision-making

ShipBob’s inventory management system provides automated reorder point notifications that trigger purchase orders before stock reaches critical levels, giving you adequate lead time to replenish inventory even when suppliers face delays.

Our intelligent inventory allocation algorithm distributes products across multiple locations based on historical demand patterns, regional sales velocity, and seasonal trends, automatically adjusting to changing consumer behavior.

The system also employs strict FIFO (First In, First Out) logic that prevents stock obsolescence and reduces waste from expired or outdated products, particularly critical for consumable goods with limited shelf life.

Streamlined inbound receiving process (WRO)

ShipBob’s Warehouse Receiving Order (WRO) system provides clear guidelines that prevent warehouse bottlenecks through standardized receiving procedures across all facilities, ensuring consistency regardless of which location receives your inventory.

This flexible approach includes support for handling unexpected overages with dynamic storage solutions and real-time inventory adjustments when suppliers ship more units than anticipated.

The Unidentifiable Receiving Order (URO) processes keep operations moving even when shipments arrive with incomplete documentation or labeling issues, maintaining fulfillment continuity while discrepancies are resolved.

Exception handling and order allocation rules for flexibility

ShipBob’s platform features configurable routing logic based on real-time inventory availability that automatically selects optimal fulfillment locations for each order, balancing speed, cost, and inventory levels.

Our destination-based fulfillment options prioritize fulfillment centers closest to delivery addresses, reducing transit times and shipping costs while minimizing carbon emissions.

During stock shortages, ShipBob enables partial shipment capabilities with automated customer communications that provide transparency about when remaining items will ship.

Ability to scale during peak seasons

ShipBob offers flexible storage options that expand with demand, including seasonal storage plans without long-term commitments—ideal for holiday merchandise, limited edition releases, or promotional inventory.

Our standardized SLAs maintain consistent order processing times and accuracy rates even during holiday surges and promotional events when order volume can increase tenfold. And, ShipBob’s proprietary technology prevents backlogs and overcapacity risks through predictive volume modeling that anticipates fulfillment needs based on historical patterns, marketing calendars, and current sales trends.

Partner with ShipBob for supply chain expertise

Leverage ShipBob as your supply chain, logistics, and fulfillment expert. Connect with our team to get a custom quote.

FAQs about supply chain issues

Below are answers to more common queries and challenges you may encounter as you tackle supply chain issues and challenges.

What are the biggest supply chain issues facing ecommerce brands today?

Ecommerce brands are grappling with a range of supply chain challenges in the current market. Some of the most pressing issues include:

- Inventory shortages and stockouts due to manufacturing delays and transportation bottlenecks. This can lead to lost sales and frustrated customers.

- Increased shipping costs and longer delivery times resulting from capacity constraints and port congestion. These issues can compress margins and make it difficult to meet customer expectations.

- Labor shortages across warehousing and logistics roles, which can slow down operations and limit flexibility during demand spikes.

While some of these disruptions may ease over time, ecommerce brands need to proactively adapt their supply chain strategies to build resilience and maintain a competitive edge

What technology investments provide the best protection against supply chain disruptions?

Investing in the right supply chain technology can help ecommerce brands mitigate the impact of disruptions and make more informed decisions. Some key technologies to consider include:

- Inventory management systems that provide real-time visibility into stock levels, location, and movement. This can help brands identify potential shortages early and take proactive steps to prevent stockouts.

- Demand forecasting tools that use historical data and machine learning to predict future needs more accurately. By anticipating demand patterns, brands can optimize inventory levels and avoid over- or under-stocking.

- Multi-carrier shipping software that automates rate shopping, label printing, and tracking. This can help brands find the most efficient and cost-effective shipping options, even when capacity is tight.

When evaluating technology investments, look for solutions that integrate seamlessly with your existing systems and provide a single source of truth across your supply chain.

How can we effectively communicate supply chain delays to customers?

Communicating supply chain delays to customers can be challenging, but transparency is key to maintaining trust and loyalty. Some best practices include:

- Be proactive: Let customers know about potential delays as soon as possible, ideally before they place an order. Use website banners, product pages, and checkout notices to set expectations upfront.

- Provide specific details: Instead of generic statements like “due to supply chain issues,” give customers a clear sense of what’s causing the delay and how long it might last. This shows that you’re actively managing the situation.

- Offer alternatives: If a product is backordered or unavailable, suggest similar items that are in stock or offer to notify the customer when the original product is available again.

Remember that customers are more likely to be understanding if you’re honest and upfront about challenges. By communicating proactively and transparently, you can turn a potentially negative experience into an opportunity to build trust.