Verified & Reviewed

Published on September 29, 2025 Written By Rachel Hand

Published on September 29, 2025 Written By Rachel Hand

Subscribe for More

In ecommerce, your ability to deliver products quickly and affordably can make or break customer loyalty. Line haul shipping can play a pivotal role in making that happen.

As the “middle mile” between suppliers, warehouses, and fulfillment centers, line haul is the engine that powers fast, reliable, and cost-efficient order delivery.

Yet despite its critical role, many ecommerce brands overlook how optimizing line haul can reduce costs, shorten transit times, and unlock 2-day delivery capabilities.

In this guide, we’ll break down what line haul is, how it fits into the ecommerce supply chain, and how to harness it to drive efficiency and growth. Whether you’re scaling your fulfillment strategy or simply want to deliver faster without cutting into margins, this guide will help you make line haul a strategic advantage.

What is line haul?

Line haul refers to the transportation of goods between two major hubs or distribution centers.

It’s the critical middle mile that connects the initial shipment from a supplier or manufacturer to the final delivery to a customer’s doorstep.

Line haul shipping is all about efficiency and economies of scale. By consolidating multiple shipments into a single truckload or container, carriers can optimize their routes and reduce per-unit shipping costs. This is especially important in the ecommerce world, where margins can be razor-thin and every penny counts.

But line haul isn’t just about cost savings; it’s also about speed and reliability. By leveraging dedicated routes and schedules, line haul carriers can provide consistent transit times and minimize the risk of delays or disruptions. This predictability is essential for ecommerce businesses that need to make firm delivery promises to their customers.

Line haul vs. last-mile and LTL shipping

While line haul, last-mile, and LTL (Less Than Truckload) shipping are all key components of the ecommerce supply chain, they each serve a distinct purpose:

- Line haul focuses on the bulk movement of goods between major hubs, such as from a manufacturer’s warehouse to a retailer’s distribution center. It’s all about efficiency and cost-effectiveness over long distances.

- Last-mile shipping is all about getting products from those distribution centers into the hands of end customers. This final leg of the journey is often the most complex and costly, as it involves navigating local roads and dealing with individual deliveries.

- LTL shipping is a bit of a hybrid between line haul and last-mile. Like line haul, it involves consolidating multiple shipments into a single truckload; unlike line haul, LTL shipments often involve multiple stops and smaller quantities of goods.

While each method has its strengths, the real magic happens when they work together seamlessly. By optimizing line haul routes and schedules, ecommerce businesses can create a more efficient and cost-effective foundation for their last-mile and LTL operations. It’s all about finding the right balance and leveraging the strengths of each approach.

5 key benefits of line haul for ecommerce

When integrated with a comprehensive fulfillment strategy, line haul shipping can unlock a powerful competitive advantage in the ecommerce marketplace. By working with experienced logistics partners or 3PLs, brands can maximize the following benefits and position themselves for success in today’s demanding retail landscape.

1. Cost efficiency and scheduling predictability

Consolidating shipments through line haul reduces per-unit shipping costs, while scheduled routes eliminate the need for premium fees associated with expedited or last-minute shipping.

Moreover, predictable schedules allow for better inventory planning and reduced safety stock, as brands can anticipate when goods will arrive at each node in their network. These savings can be passed on to customers through competitive pricing or reinvested into the business to improve profit margins.

2. Faster transit for multi-node fulfillment

Strategic line haul routes connect multiple fulfillment centers, creating a distributed inventory network that reduces the distance to end customers. By placing products closer to key markets, brands can significantly improve transit times and meet the growing demand for fast delivery.

Wholesome Goods, a health and wellness brand, saw a dramatic improvement in delivery speed after implementing a multi-node fulfillment strategy with ShipBob:

“When we were shipping orders from our warehouse, orders were delivered in 5 to 6 days. With ShipBob, we’re averaging around 3 days. The fact that ShipBob works with so many different carriers to ensure customers are getting their orders quickly is a great benefit for us.”

Cesar Contreras, Head of Supply Chain of Wholesome Goods

3. Reliable bulk transport between hubs

Dedicated routes and schedules create consistency in transit times, enabling more accurate delivery promises to customers. This reliability is further enhanced by the efficiencies of bulk transport, which reduces handling and potential damage to products en route.

Consistent delivery timelines also help with staffing and resource planning at destination facilities, as managers can anticipate when shipments will arrive and allocate labor accordingly.

4. Flexible modes of transportation

Line haul shipping can utilize various modes of transportation, including truck, rail, air, and sea, based on specific needs and requirements. Intermodal solutions, which combine two or more modes, can maximize efficiency for different product types and shipping scenarios. For example, a brand may choose to use truck line haul for domestic shipments, while opting for sea freight when importing goods from overseas.

Seasonal demand fluctuations might also influence mode selection, with air freight becoming more viable during peak periods. By working with a supply chain enablement partner like ShipBob, brands gain access to multiple transportation options and the expertise to choose the most appropriate mode for each situation.

5. Improved customer satisfaction and 2-day delivery capabilities

Efficient line haul operations are directly tied to meeting customer expectations for fast delivery and can serve as the foundation for offering competitive 2-day shipping.

Earthley, a natural health products brand, experienced firsthand the impact of improved delivery speed on customer satisfaction and sales. After partnering with ShipBob, the company cut lead times by 4 days and doubled its monthly order volume within just six months.

“ShipBob’s WMS has more than doubled, if not tripled, our productivity in terms of labor hours. Our average days to ship is now only 0.8 days, so most packages are shipping same-day or next-day, with rare exceptions. We’ve cut 4 days of lead time because orders are getting processed, fulfilled, and shipped more efficiently. When we first started with ShipBob, we were doing about 15K orders per month, and now we’re processing 30K — double what we were doing just six months ago.”

Ben Tietje, Co-Founder and CEO of Earthley

Consistent delivery experiences also build brand trust and reduce customer service issues, leading to positive reviews and repeat purchases. By leveraging line haul shipping as part of a comprehensive fulfillment strategy, brands can create a virtuous cycle of growth and customer loyalty.

How line haul fits into the ecommerce supply chain

Line haul plays a crucial role in the ecommerce supply chain, serving as the vital link between warehouses, fulfillment centers, and distribution points. It’s the glue that holds the entire logistics network together, ensuring that products move efficiently from one node to the next.

In a typical ecommerce scenario, line haul carriers pick up bulk shipments from a supplier or manufacturer and transport them to a fulfillment center. From there, the products are stored until an order is placed, at which point they are picked, packed, and shipped to the end customer, often via last-mile delivery.

This seamless integration of line haul with other supply chain components creates the foundation for reliable delivery promises. When line haul operations are optimized, brands can confidently offer fast shipping options, knowing that their inventory will arrive at fulfillment centers on time and in good condition.

Efficient line haul also directly impacts inventory availability and customer satisfaction. By reducing transit times and minimizing the risk of delays or damage, brands can maintain adequate stock levels and avoid backorders or stockouts. This, in turn, leads to a better customer experience, as shoppers can trust that the products they want will be available when they need them.

To visualize how line haul fits into the bigger picture, consider the following supply chain flow:

As you can see, line haul acts as the critical middle mile, connecting the dots between the initial supply and the final delivery. Without a well-oiled line haul operation, the entire supply chain would grind to a halt, leading to delays, dissatisfied customers, and lost sales.

How line haul carriers operate

Line haul carriers are responsible for moving goods efficiently and reliably between major hubs in the supply chain.

To achieve this, they rely on a complex network of terminals, trucks, and logistics professionals working together to optimize routes and maximize load capacity.

The typical line haul process flow goes something like this:

- Pickup: Carriers collect bulk shipments from suppliers, manufacturers, or warehouses. This often involves consolidating multiple shipments into a single truckload to improve efficiency.

- Terminal operations: Shipments are brought to a carrier’s terminal, where they are sorted, staged, and loaded onto outbound trucks. This is where a lot of the logistical magic happens, as carriers work to optimize routes and ensure that each truck is filled to capacity.

- Line haul transport: Trucks depart from the terminal on a predetermined schedule, often with designated departure windows to ensure timely arrival at the destination. During this stage, the shipments are en route to their next stop, whether that’s another terminal, a fulfillment center, or a distribution hub.

- Delivery: Upon arrival at the destination, the shipments are unloaded and processed for the next leg of their journey. This might involve sorting products for last-mile delivery, storing them in a warehouse, or preparing them for pickup by another carrier.

Throughout this process, line haul carriers rely on sophisticated scheduling and routing software to optimize their operations. This includes factoring in cutoff times for pickup and delivery, as well as strategically planning routes to minimize distance and maximize efficiency.

Major line haul carriers, such as FedEx Freight, UPS Freight, and Old Dominion, have extensive networks that span the country, allowing them to provide fast and reliable service to a wide range of locations. However, capacity constraints can sometimes impact operations, particularly during peak seasons like the holidays.

To mitigate these challenges, many carriers offer expedited services for time-sensitive shipments, as well as guaranteed delivery options for an additional fee. They also work closely with shippers to forecast demand and plan accordingly, ensuring that there is sufficient capacity to meet the needs of their customers.

Understanding common line haul shipping statuses

When tracking a line haul shipment, you may encounter various status updates that can be confusing or unclear. Here’s a quick guide to some of the most common statuses and what they mean:

- “Arrived at line haul office”: This status indicates that your shipment has reached the carrier’s terminal and is being processed for outbound transport. Packages typically remain in this status for 1-2 days, depending on the carrier’s schedule and workload.

- “Failed to hand over”: If you see this status, it means that there was an issue transferring your shipment from one carrier to another. This could be due to missing paperwork (such as a shipping manifest), incorrect labeling, or a missed pickup. The carrier will usually attempt to resolve the issue and update the status accordingly.

- “Handed over to line haul”: This status means that your shipment has been successfully transferred to the line haul carrier and is now in transit to its next destination. Transit times vary depending on distance and mode, but most line haul shipments arrive within 2-5 days.

Other common statuses you might see include “In transit,” “Out for delivery,” and “Delivered.” Each of these indicates a specific stage in the shipping process and helps you track the physical movement of your goods.

If a package remains in a particular status for an unusually long time, it may be cause for concern. In these cases, it’s best to reach out to the carrier or your logistics provider for more information and assistance.

Calculating and managing line haul costs

Line haul pricing can be complex, with various factors influencing the final cost of shipping. Some of the most common pricing variables include:

- Distance: The farther your shipment needs to travel, the more expensive it will be. Many carriers use zone-based pricing, where rates are determined by the distance between the origin and destination zip codes.

- Weight: Heavier shipments generally cost more to transport, as they require more fuel and labor to move. Most carriers use a combination of actual weight and dimensional weight (a calculation based on the size of the package) to determine the billable weight for each shipment.

- Dimensions: Larger packages take up more space on a truck, which can impact the carrier’s ability to optimize their loads. As a result, many carriers apply dimensional weight pricing, which takes into account both the size and weight of a package.

- Fuel surcharges: Line haul carriers often add a fuel surcharge to their rates to account for fluctuations in the cost of diesel. These surcharges can vary based on market conditions and are typically adjusted on a weekly or monthly basis.

To get the best rates on line haul shipping, consider the following strategies:

- Negotiate with carriers: If you have a high volume of shipments, you may be able to negotiate better rates with your carrier. Be sure to shop around and compare prices from multiple providers to ensure you’re getting the best deal.

- Consolidate shipments: Whenever possible, consolidate multiple shipments into a single truckload. This can help you qualify for volume discounts and reduce your overall shipping costs.

- Optimize packaging: Use appropriately sized boxes and packaging materials to minimize dimensional weight charges. Avoid using oversized or irregularly shaped packages, as these can be more expensive to ship.

- Plan ahead: Shipping during peak seasons can be more expensive due to increased demand and capacity constraints. If possible, plan your shipments in advance and avoid shipping during busy times like the holidays.

- Evaluate accessorial charges: In addition to base rates, carriers often charge for additional services like inside delivery, liftgate service, or residential delivery. Be sure to factor these charges into your total shipping costs and look for ways to minimize them where possible.

By understanding how line haul pricing works and implementing these cost-saving strategies, you can keep your shipping expenses under control and improve your bottom line.

Avoiding common line haul bottlenecks and delays

Even the most well-planned line haul operation can encounter delays and disruptions from time to time. Some of the most common causes of line haul bottlenecks include:

- Weather events: Inclement weather, such as snowstorms, hurricanes, or flooding, can impact road conditions and cause delays in transit.

- Capacity constraints: During peak shipping seasons, carriers may struggle to keep up with demand, leading to longer transit times and potential delays.

- Equipment failures: Mechanical issues with trucks or other equipment can cause unexpected delays and disrupt the flow of goods through the supply chain.

- Labor shortages: A lack of qualified drivers or warehouse workers can impact a carrier’s ability to move shipments efficiently and on time.

While some of these factors are beyond your control, there are steps you can take to mitigate the risk of delays and keep your shipments moving smoothly:

- Plan ahead: Build extra lead time into your shipping schedule to account for potential delays. This is especially important during peak seasons or when shipping to areas prone to weather disruptions.

- Communicate with your carrier: Maintain open lines of communication with your line haul carrier and logistics provider. Notify them of any special requirements or time-sensitive shipments in advance, and work together to develop contingency plans for potential disruptions.

- Leverage technology: Use real-time tracking and visibility tools to monitor your shipments and identify potential issues before they become major problems. This can help you proactively address delays and keep your customers informed of any changes to their expected delivery dates.

- Diversify your carrier network: Don’t put all your eggs in one basket. Work with multiple carriers and logistics providers to ensure that you have backup options in case of capacity constraints or other issues.

- Focus on prevention: Implement quality control measures and best practices throughout your supply chain to minimize the risk of delays. This might include proper packaging and labeling of shipments, regular equipment maintenance, and ongoing training for your logistics team.

By taking a proactive approach to line haul management and focusing on prevention rather than reaction, you can minimize the impact of delays and disruptions on your business. This, in turn, can help you build a more resilient and efficient supply chain that delivers a competitive advantage in the marketplace.

How to leverage line haul for a competitive 2-day delivery strategy

In today’s fast-paced ecommerce landscape, offering 2-day delivery has become table stakes for many brands. Consumers have come to expect fast, affordable shipping, and they’re willing to shop around to find it.

To make sure your brand can provide the fast, affordable shipping customers demand, here are some best practices to make your line work for you, not against you.

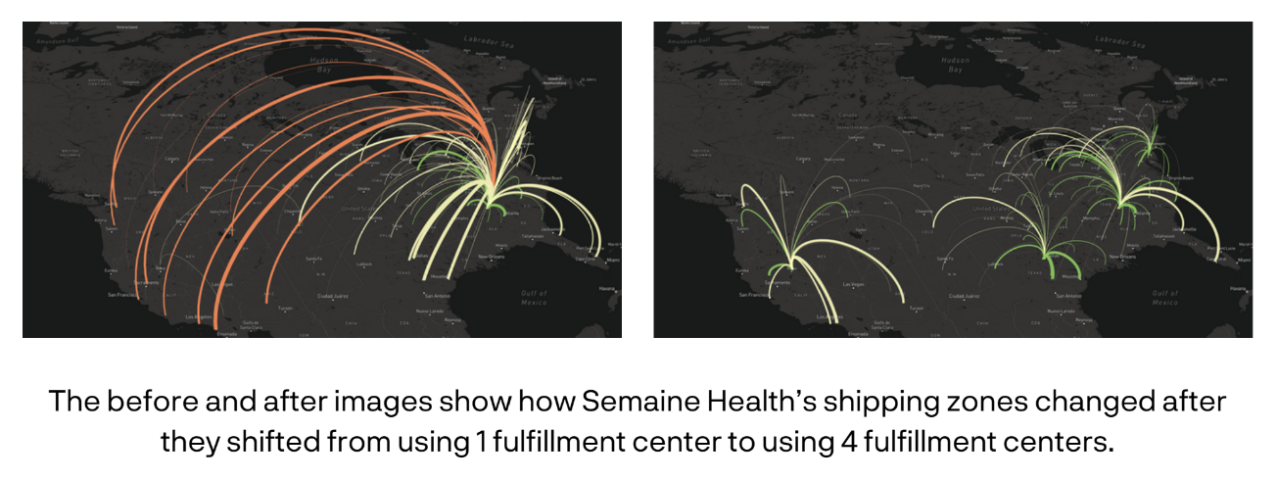

Leverage distributed inventory and fulfillment center networks

Many brands are turning to strategic line haul operations as the foundation of their 2-day delivery strategy. By leveraging a network of strategically located fulfillment centers and optimizing their line haul routes, these brands are able to offer fast, affordable shipping to a wide range of customers.

One of the key benefits of this approach is that it allows brands to distribute their inventory closer to their end customers. By storing products in multiple fulfillment centers across the country, brands can reduce the distance that packages need to travel to reach their final destination. This, in turn, reduces transit times and makes it easier to meet 2-day delivery promises.

For example, a brand with a single fulfillment center on the West Coast might struggle to offer 2-day shipping to customers on the East Coast, as packages would need to travel across multiple shipping zones. However, by distributing their inventory to fulfillment centers in strategic locations like the Midwest and the East Coast, that same brand could offer 2-day shipping to a much larger portion of their customer base.

Plan well in advance and work closely with carriers

Of course, implementing a multi-node fulfillment strategy like this requires careful planning and execution. Brands need to have a deep understanding of their customer demographics and shipping patterns in order to determine the optimal locations for their fulfillment centers. They also need to work closely with their line haul carriers and logistics providers to ensure that their shipping routes are optimized for speed and efficiency.

Strategic line haul operations can be a powerful tool for brands looking to compete with the likes of Amazon and other ecommerce giants. By optimizing their shipping routes and distributing their inventory closer to their customers, brands can offer the fast, affordable shipping that consumers have come to expect, without breaking the bank.

How ShipBob optimizes/integrates line haul shipping for ecommerce brands

At ShipBob, we understand that line haul is a critical component of any successful ecommerce fulfillment strategy. That’s why we’ve built comprehensive solutions that integrate line haul shipping with our best-in-class fulfillment services, giving brands the tools and support they need to compete in today’s fast-paced marketplace.

Global fulfillment center network for optimized distribution

Our approach starts with our network of strategically located fulfillment centers, which are designed to help brands distribute their inventory closer to their end customers. By storing products in multiple locations across the country, we can reduce the distance that packages need to travel, which in turn reduces transit times and makes it easier to offer fast, affordable shipping.

“I totally get why consumers prefer local deliveries: shorter wait times, less expensive shipping, and avoiding surprise tariffs or fees. That’s why it’s so important to have fulfillment centers in areas that I wanted to grow into, so that customers aren’t deterred and can get a fantastic delivery experience no matter where they live. With ShipBob’s global network, we can achieve that.”

Luke Rolls, Founder of The Protein Pancake

Carrier partnerships for speedy, cost-effective fulfillment

But our line haul optimization doesn’t stop there. We also work closely with our carrier partners to ensure that our shipping routes are optimized for speed and efficiency. Our technology platform provides real-time visibility into inventory levels and shipping patterns, allowing us to make data-driven decisions about how to route orders and minimize transit times.

“Our subscribers are some of our closest, most valued customers, so we want to give them the option of receiving their first order in 2 days. With ShipBob, we can make that happen. Not only that, we can make it happen without compromising on cost. Because of ShipBob’s overall order volume, they can negotiate bulk discounts with carriers that we simply couldn’t. By partnering with ShipBob, we get better quality fulfillment and shipping for a better price.”

Maria Osorio, Logistics and Operations Director at Oxford Healthspan

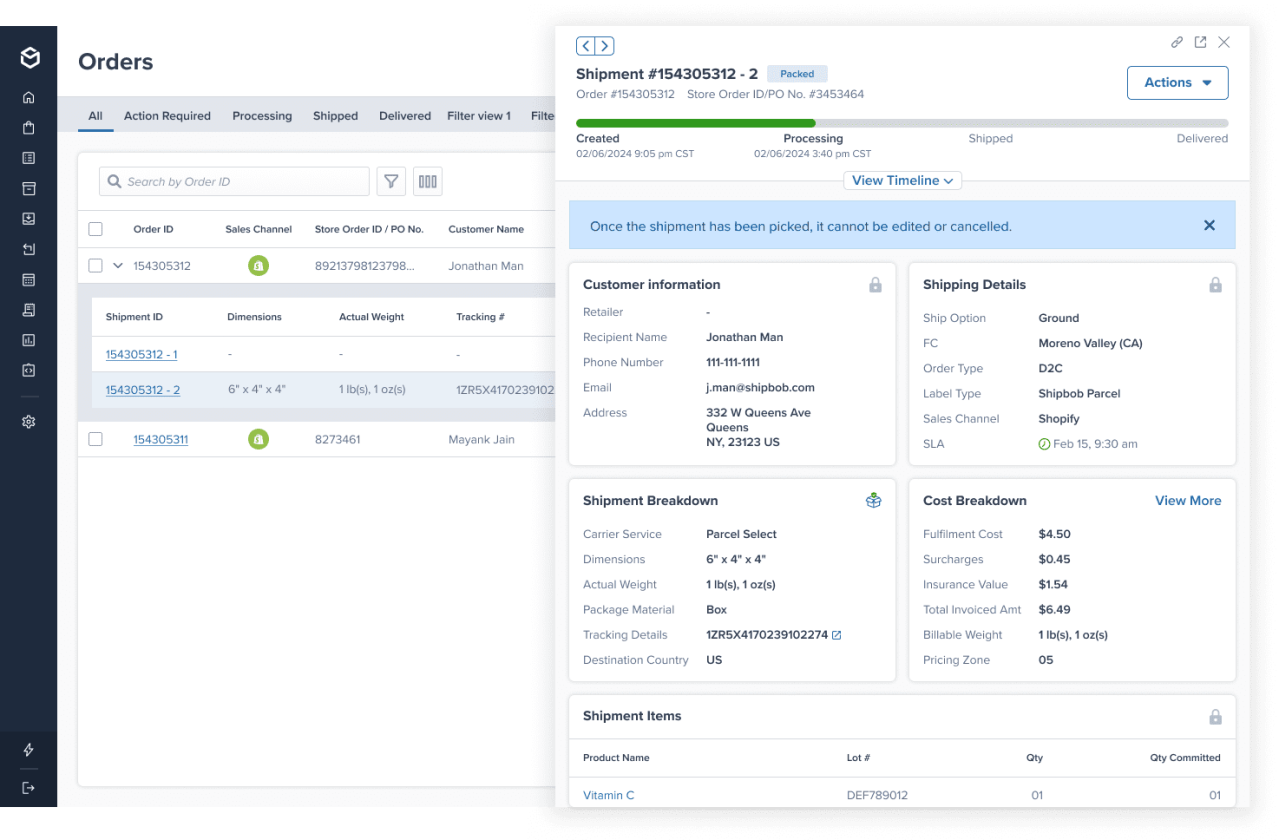

User-friendly dashboard for real-time updates

One of the key benefits of partnering with ShipBob is the level of visibility and control that our technology platform provides. Our dashboard gives brands real-time insights into their inventory levels, order status, and shipping performance, allowing them to make informed decisions about their fulfillment strategy.

For example, our platform allows brands to set up custom shipping rules based on factors like order value, product weight, and shipping destination. This means that brands can automatically route orders to the fulfillment center that offers the fastest and most cost-effective shipping option, without having to manually intervene in the process.

“Another aspect of ShipBob’s solutions suite that makes our lives easier is the dashboard. You can tell that they put a lot of thought into building a system that brands would actually use. There are so many different reports that we can pull to see how we’re performing across inventory, fulfillment, and shipping, and they provide the right information exactly when we need it. The ShipBob dashboard also comes with features you don’t even realize you wanted, like the ability to make claims with carriers with one click of a button. It’s a huge time saver, and something that we didn’t even think about optimizing. But ShipBob was ahead of the curve. They built it in, reached out to us about it, and helped us start using it. We love that they take initiative like that and love that our 3PL partner has that same drive.”

Hayden Pembridge, VP of Operations at Nood

Brand-centered custom packaging and kitting and assembly services

We also offer a range of value-added services that can help brands optimize their line haul operations even further. For example, our kitting and assembly services allow brands to bundle products together before they’re shipped, reducing the number of individual packages that need to be transported and minimizing shipping costs.

“The thing I love most about ShipBob’s dashboard is the product bundling capability. I can’t explain how many conversations we’ve had internally trying to figure our bundling before we worked with ShipBob. You would not believe how hard it was to configure bundles so that the customer sees it as one unit, but it would get split into different picks when it got to the old 3PL’s fulfillment center. But with ShipBob, it’s so simple. You log on to your dashboard, put whatever products you want in a bundle, and it’s created as its own “primary item” on Shopify with the composite products as sub-items. When an order comes through, it triggers the system and gets fulfilled seamlessly. It’s super easy – that alone would have been enough to make me want to switch to ShipBob!”

Stuart Jones, Co-Founder of Canvas

If you’re looking to take your line haul strategy and ecommerce business to the next level, clock the button below to get in touch.

FAQs about line haul in shipping

Here are answers to some of the most common questions about line haul shipping.

What’s the difference between line haul and long haul?

Line haul typically involves the movement of freight between two major hubs or terminals, often as part of a larger distribution network. These routes are usually fixed and operate on a regular schedule.

On the other hand, long haul generally refers to the transportation of goods over an extended distance, often across state lines or even internationally. Long haul routes may vary based on the specific needs of the shipper and can involve a single driver covering the entire distance.

What does line haul mean for shipping times?

Line haul plays a crucial role in determining overall shipping times. When line haul operations are well-optimized, it enables faster and more predictable shipping times for end customers. This is because the bulk transportation of goods between fulfillment centers, distribution points, and other key nodes in the supply chain is streamlined, reducing potential delays and bottlenecks.

How long does line haul typically take?

The duration of a line haul trip can vary significantly depending on several factors, including the distance between origin and destination, the mode of transportation used (truck, rail, air, etc.), and any potential delays or disruptions along the route.

For domestic line haul shipments within the United States, transit times can range from a single day for shorter distances to several days for coast-to-coast trips. For example, a line haul shipment from Los Angeles to New York might take around 4-5 days by truck, while a shorter trip from Chicago to Detroit could be completed in a day.

International line haul shipments will naturally take longer, with transit times potentially extending to weeks depending on the specific route and transportation method.

How are line haul costs calculated?

Line haul costs are typically calculated based on a combination of factors:

- The total distance covered by the shipment: Longer distances generally result in higher costs.

- The size and weight of the shipment: Larger and heavier loads will typically incur higher costs.

- Different modes of transportation (truck, rail, air, etc.) with varying cost structures: For example, shipping by air is generally more expensive than ground transportation.

- Fuel surcharges: These surcharges account for fluctuations in fuel costs and can vary based on market conditions.

- Additional services: Liftgate service, inside delivery, or residential delivery can incur extra fees on top of the base line haul cost.

What happens after line haul?

After a line haul shipment arrives at its destination terminal or hub, the goods are typically processed and prepared for the next stage in the shipping journey.

- Individual shipments are sorted and segregated based on their final delivery destination.

- In some cases, goods may be immediately unloaded from the line haul vehicle and reloaded onto another vehicle for the next leg of the trip, without being stored in the facility.

- If the goods are not immediately shipped out, they may be temporarily stored in a warehouse or distribution center until they are ready for the next stage of the shipping process.

- Once the goods have been processed at the destination terminal, they are typically loaded onto smaller vehicles for final delivery to the end customer.

How does ShipBob help with line haul shipping?

ShipBob is a leading logistics platform that provides a range of solutions to help ecommerce businesses optimize their line haul shipping operations. Here are some of the key ways ShipBob supports line haul:

- ShipBob operates a network of fulfillment centers across the United States and in several international locations. This distributed infrastructure allows merchants to strategically position their inventory closer to end customers, reducing the distance and time required for line haul shipping.

- ShipBob works with a wide range of trusted line haul carriers, leveraging these relationships to secure competitive rates and ensure reliable service for merchants.

- ShipBob’s proprietary software platform provides real-time visibility into the status of line haul shipments, enabling merchants to track their goods and make informed decisions about their supply chain.

- Whether a merchant needs support with inbound line haul (getting inventory to ShipBob’s fulfillment centers) or outbound line haul (shipping orders to customers), ShipBob offers adaptable solutions to meet the unique needs of each business.