Verified & Reviewed

Published on November 20, 2025 Written By Meredith Flora

Published on November 20, 2025 Written By Meredith Flora

Subscribe for More

Fulfilling ecommerce orders quickly and accurately is a competitive necessity. As order volumes rise and customer expectations grow, warehouses are ditching outdated, paper-based workflows in favor of smarter, more scalable solutions.

Enter paperless picking.

Paperless picking uses digital tools to streamline order fulfillment, replacing pick slips with mobile devices, scanners, and real-time inventory data. The result? Fewer errors, faster processing, better visibility, and a fulfillment operation that can actually keep up with demand.

In this guide, we’ll break down how paperless picking works, where it shines, and how to implement it effectively.

What is paperless picking?

Paperless picking is a modern approach to warehouse order fulfillment that replaces traditional paper-based methods with digital technologies and automated systems. By eliminating the need for printed pick lists, packing slips, and other manual paperwork, paperless picking streamlines the entire order fulfillment process.

With paperless picking, digital devices such as barcode scanners, mobile computers, and wearable technology guide pickers through their tasks. These devices communicate with the warehouse management system (WMS) to provide real-time instructions, ensuring that the right products are selected for each order.

6 reasons to switch to paperless picking

Paperless picking transforms warehouse operations beyond simply eliminating paper. Here are six compelling reasons to make the switch:

1. Reduced picking errors and improved accuracy

By utilizing barcode scanning and digital verification, paperless picking systems significantly reduce human error compared to traditional paper-based methods. This directly impacts customer satisfaction as orders are fulfilled accurately and returns are minimized.

2. Faster order fulfillment speeds

Eliminating the need for paper handling and manual processes accelerates the picking process, enabling warehouses to fulfill orders faster than ever before. Real-time task assignment optimizes picker routes and reduces travel time, ensuring that orders are processed efficiently.

By streamlining the picking process, businesses can meet the growing customer expectations for rapid shipping and shorter delivery windows.

3. Real-time inventory visibility and management

One of the most significant advantages of paperless picking is the ability to update inventory counts instantly with each pick. This real-time visibility prevents overselling and helps businesses make informed decisions about inventory management.

With accurate, up-to-date data, warehouses can identify slow-moving products, optimize their layout, and improve overall efficiency.

4. Significant cost savings

Implementing a paperless picking system not only eliminates direct costs associated with paper, printing, and storage but also leads to substantial indirect savings through improved labor efficiency and reduced errors. Businesses can expect to see a significant return on investment (ROI) when transitioning to paperless picking. These savings can be reinvested in business growth and further optimization efforts.

5. Enhanced sustainability and eco-friendly operations

By eliminating paper from picking operations, businesses can significantly reduce their environmental impact. A single warehouse can save thousands of sheets of paper annually, contributing to a greener and more sustainable operation.

As consumers increasingly prioritize eco-conscious brands, implementing paperless picking can help businesses align with these preferences and incorporate sustainability initiatives into their marketing efforts.

6. Improved scalability for business growth

Paperless picking systems are designed to adapt seamlessly to increased order volumes, making them ideal for businesses looking to scale their operations. Digital processes facilitate expansion to multiple fulfillment locations, ensuring that growth is not hindered by paper-based methods.

By implementing standardized digital workflows, businesses can maintain consistency across their operations, regardless of size or location.

Paperless picking technologies and methods

Paperless picking is made possible through a variety of innovative technologies and methods that work together to create a seamless, digital workflow. By combining these solutions, warehouses can optimize their operations for maximum efficiency and accuracy.

Pick-by-voice systems

Pick-by-voice systems are a hands-free solution that allows pickers to receive instructions through a headset and confirm their actions using verbal commands. This technology frees up workers’ hands, enabling them to focus on the picking process without the need to hold a device or paper list. Voice-directed picking not only improves productivity but also enhances safety by allowing pickers to maintain awareness of their surroundings.

Pick-by-light solutions

Pick-by-light technology uses LED displays mounted on shelves or racks to guide pickers to the correct location and indicate the quantity of items to pick. This solution is particularly effective in high-density picking areas or when dealing with small, easily mixed-up items.

By providing visual cues, pick-by-light systems can significantly reduce the time spent searching for products and minimize the risk of errors. While implementation costs can be higher compared to other paperless picking technologies, the efficiency gains often justify the investment.

Mobile devices and handheld scanners

One of the most accessible paperless picking solutions is the use of mobile devices, such as smartphones, tablets, or purpose-built handheld scanners. These devices allow pickers to receive digital pick lists, scan barcodes to confirm selections, and update inventory levels in real-time.

The flexibility of mobile devices makes them suitable for businesses of all sizes, and the widespread adoption of cloud-based software has made implementation more straightforward than ever. With a variety of hardware options available, warehouses can select the devices that best fit their needs and budget.

Wearable technology options

As technology continues to advance, newer solutions like smart glasses and wrist-mounted scanners are gaining traction in the world of paperless picking. These wearable devices provide digital picking instructions while keeping workers’ hands free, allowing for even greater efficiency and accuracy. Smart glasses, for example, can display pick lists, product images, and location information directly in the picker’s field of vision, reducing the need to look down at a device or paper. While these technologies are still evolving, they hold immense potential for revolutionizing warehouse operations in the near future.

WMS and ERP integration requirements

To fully leverage the benefits of paperless picking, it’s crucial to ensure that your chosen technology integrates seamlessly with your existing warehouse management system (WMS) and enterprise resource planning (ERP) software. This integration allows for real-time data exchange between systems, enabling accurate inventory tracking, order updates, and performance monitoring.

When evaluating paperless picking solutions, consider the API requirements and data synchronization capabilities to ensure a smooth integration process. By establishing a robust connection between your paperless picking technology and your core business systems, you can unlock the full potential of digital workflows and make data-driven decisions to optimize your operations.

How to implement paperless picking in your warehouse: 5 steps

Transitioning from paper-based to paperless picking requires careful planning and change management. Here’s an actionable roadmap to help you make the switch with confidence, regardless of your business size.

Assess your current picking processes

Begin by conducting a thorough analysis of your existing workflows. Identify bottlenecks and paper-dependent processes that could be streamlined through digitization. Establish baseline metrics, such as picking accuracy and order processing times, to measure improvement later.

Select the right technology for your operation

Evaluate different paperless picking solutions based on criteria such as scalability, ease of use, and compatibility with your existing systems. Compare vendors and technologies using a framework that considers your specific needs and budget. Don’t forget to factor in future growth when making your decision.

Develop infrastructure and integration requirements

Ensure your warehouse has the necessary technical prerequisites, such as reliable WiFi coverage, sufficient power outlets, and a plan for device management. Determine the integration points between your new paperless picking system and existing software, such as your warehouse management system (WMS), enterprise resource planning (ERP) software, and ecommerce platforms. Prioritize data security and establish backup protocols to protect your business.

Create a comprehensive training program

Develop a training program that caters to different learning styles and technical comfort levels. Use a mix of hands-on demonstrations, written instructions, and video tutorials to ensure all staff members are comfortable with the new technology. Identify and cultivate internal champions who can help guide their peers through the transition.

Implement with a phased rollout approach

Start with a pilot program in a specific area of your warehouse to test the new system and gather feedback. Use this information to refine your processes before gradually expanding the rollout to other sections. Provide ongoing support and encourage open communication throughout the implementation to ensure a smooth transition.

By following this roadmap and adapting it to your unique needs, you can successfully implement paperless picking in your warehouse and start reaping the benefits of increased efficiency, accuracy, and scalability.

Strategic advantages of paperless picking beyond efficiency

While the operational benefits of paperless picking are clear, implementing this technology also offers strategic advantages that can help your business stand out in a competitive market.

By leveraging the data and capabilities provided by paperless systems, you can enhance your brand reputation, optimize inventory decisions, scale operations with ease, and ultimately improve the customer experience.

Enhanced brand reputation through sustainability

Adopting paperless picking demonstrates your commitment to environmental sustainability, which can be a powerful differentiator in today’s eco-conscious market. By calculating the amount of paper waste eliminated through your digital processes, you can communicate the tangible impact of your efforts to customers and stakeholders. Incorporating these sustainability metrics into your marketing materials and website can attract environmentally-minded consumers and position your brand as a leader in responsible business practices.

Optimized inventory decisions using insightful data

Paperless picking systems generate a wealth of real-time data that can inform strategic inventory decisions. By analyzing picking patterns, product velocity, and seasonal trends, you can optimize your inventory levels and avoid stockouts or overstocking. This data-driven approach to inventory management gives you a competitive edge, ensuring that you always have the right products in stock to meet customer demand. With the insights gained from paperless picking, you can make proactive purchasing decisions and stay ahead of the curve in your market.

Scalable operations for seasonal peaks and growth

As your business grows and experiences seasonal fluctuations, paperless picking systems provide the flexibility and scalability needed to adapt quickly. Digital processes can be easily replicated across multiple warehouse locations, ensuring consistent operations and a seamless customer experience. During peak periods, such as holidays or sales events, paperless systems allow you to onboard and train temporary staff quickly, as digital instructions are easy to follow and require minimal manual intervention. By leveraging the scalability of paperless picking, you can confidently take on new opportunities and expand your business without operational constraints.

Improved customer experience through accuracy and speed

Ultimately, the strategic advantages of paperless picking all contribute to a better customer experience. By reducing errors and increasing fulfillment speed, you can consistently deliver orders accurately and on time. This level of service builds trust and loyalty among your customers, leading to positive reviews, repeat purchases, and word-of-mouth referrals. To maximize the impact of your paperless picking system, consider communicating your commitment to accuracy and speed in your marketing materials and order confirmation emails. By highlighting your investment in technology and efficient processes, you can differentiate your brand and give customers confidence in their purchasing decisions.

How ShipBob’s paperless picking technology drives ecommerce success

At ShipBob, we understand the critical role that efficient and accurate order fulfillment plays in the success of ecommerce businesses. That’s why our fulfillment centers utilize advanced paperless picking technologies as part of our commitment to providing best-in-class logistics solutions. By partnering with ShipBob, your brand can leverage our cutting-edge systems to streamline operations, reduce costs, and deliver an exceptional customer experience.

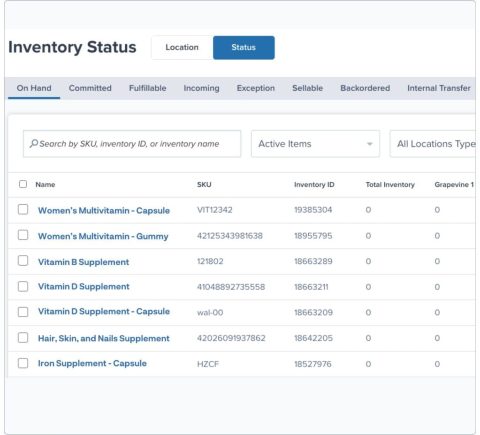

Real-time inventory management across a global network

ShipBob’s proprietary warehouse management system (WMS) provides real-time visibility into your inventory levels across our entire global network of fulfillment centers. This powerful technology enables you to monitor stock levels, track inventory movements, and make informed decisions about product allocation. By strategically distributing your inventory across our network, you can reduce shipping distances and improve delivery speeds, ensuring that your customers receive their orders quickly and efficiently.

Barcode scanning for 99.9% picking accuracy

To maintain the highest levels of accuracy, ShipBob’s paperless picking process includes a multi-scan verification system. By scanning products at multiple points throughout the picking and packing process, we can catch and correct any potential errors before orders are shipped. This rigorous approach results in an industry-leading 99.9% picking accuracy rate, significantly reducing the risk of returns and enhancing customer satisfaction. With ShipBob’s technology-driven accuracy, you can have confidence that your orders will be fulfilled correctly every time.

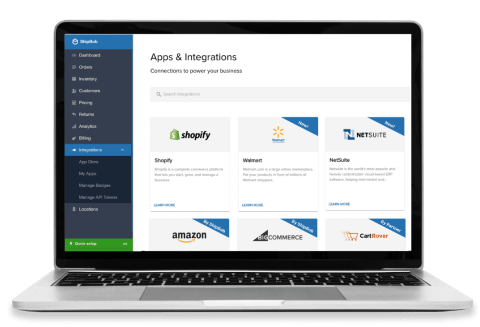

Seamless integration with your ecommerce platforms

ShipBob’s paperless picking system integrates seamlessly with leading ecommerce platforms, including Shopify, Amazon, and BigCommerce. This direct connection eliminates the need for manual order entry, reducing the risk of errors and delays in the fulfillment process. As orders are placed on your online store, they are automatically sent to ShipBob’s system for processing, ensuring that your customers’ packages are shipped as quickly as possible. Plus, real-time order status updates flow back to your selling channels, keeping your customers informed every step of the way.

Environmentally responsible fulfillment practices

In addition to the efficiency gains of paperless picking, ShipBob is committed to reducing our environmental impact through sustainable practices. By eliminating paper waste and optimizing our operations, we can minimize our carbon footprint and support your brand’s environmental goals. When you partner with ShipBob, you can feel confident that your fulfillment operations are not only technologically advanced but also environmentally responsible.

Get started with ShipBob

Ready to improve your fulfillment? Partner with ShipBob for scalable, efficient picking, packing, and shipping.

FAQs about paperless picking

We’ve answered more of your burning questions and queries in the FAQs below.

What are the costs involved in implementing paperless picking?

Implementing a paperless picking system can vary in cost depending on factors such as the size of your warehouse, order volume, and the specific technologies you choose. Common expenses include hardware (scanners, mobile devices, etc.), software licenses, integration fees, and staff training.

For smaller operations, cloud-based solutions and mobile apps can provide a more affordable entry point. Larger enterprises may invest in more extensive infrastructure like voice-directed systems or light-directed picking modules.

How long does it take to transition to a paperless picking system?

For smaller warehouses with straightforward processes, the switch can be completed in a matter of weeks. Larger enterprises with multiple locations and complex integrations may require several months.

Factors that can impact the timeline include the need for infrastructure upgrades, the level of customization required, and the availability of internal resources for training and change management. A phased rollout approach, starting with a pilot program in a specific area, can help manage the transition and ensure a smooth adoption.

Which industries benefit most from paperless picking?

Paperless picking can improve efficiency in any industry that involves order fulfillment, but some sectors stand to gain more than others.

Ecommerce and retail businesses (particularly those dealing with high SKU counts and large order volumes) can significantly benefit from the increased accuracy and speed provided by paperless systems.

Industries with strict traceability requirements, such as food and beverage, can leverage paperless picking to maintain detailed digital records and ensure compliance.

How do you measure the ROI of paperless picking implementation?

Start by identifying the key metrics that align with your business goals. Common metrics include picking accuracy rates, order fulfillment times, labor costs per order, and customer satisfaction scores.

Establish baseline measurements for these metrics prior to implementation, then track improvements over time. Quantify the financial impact of these improvements, such as the cost savings from reduced errors or the revenue gains from increased order capacity.

Compare these benefits to the total cost of implementation to determine the ROI.

Can small businesses benefit from paperless picking or is it only for large operations?

Paperless picking is not just for large enterprises; small businesses can also reap significant benefits from adopting these technologies. Cloud-based solutions and mobile apps have made paperless picking more accessible and affordable for smaller operations.

By eliminating manual processes and improving accuracy, small businesses can punch above their weight and compete with larger players in terms of fulfillment speed and customer satisfaction. Paperless systems also provide valuable data insights that can help small businesses make informed inventory management and growth decisions.

How does ShipBob’s paperless picking system compare to implementing your own?

Partnering with ShipBob for paperless picking offers several advantages over trying to implement your own system. ShipBob’s fulfillment centers are equipped with advanced scanning technologies and optimized processes, allowing you to leverage their expertise without the learning curve or upfront investment.

With ShipBob, you can tap into a global network of strategically located fulfillment centers, each utilizing standardized paperless workflows to ensure consistent performance. ShipBob’s proprietary WMS seamlessly integrates with your ecommerce platforms, providing real-time visibility and control over your inventory.