Verified & Reviewed

Last updated on November 21, 2025 Written By Rachel Hand

Last updated on November 21, 2025 Written By Rachel Hand

Subscribe for More

Sorting might not steal the spotlight in ecommerce logistics, but behind the scenes, it’s one of the most essential drivers of speed and accuracy in fulfillment. As order volumes grow and customer expectations rise, efficient warehouse sorting becomes the difference between smooth operations and costly delays.

At its core, warehouse sorting is about getting the right products to the right place at the right time – whether that means organizing inbound inventory, prepping items for picking, or routing packed orders for final shipment.

When optimized, sorting cuts down errors, speeds up fulfillment, and supports scalable growth. When it’s inefficient, it can create bottlenecks that ripple across the entire supply chain.

In this guide, we’ll unpack the role of warehouse sorting in modern ecommerce, break down the most effective methods and technologies, and share best practices for keeping your operation agile, accurate, and ready to scale.

What is warehouse sorting?

Warehouse sorting is the process of organizing and routing products within a fulfillment center to ensure orders are shipped accurately and efficiently.

Warehouse sorting acts as the connective tissue between different warehouse operations, linking the receiving of inventory to the final shipping of orders.

In the world of “sorting in warehouse” and “sortation in warehouse,” there are a few key terms to understand:

- Sortation: The automated or manual process of separating items based on specific criteria, such as destination, shipping method, or product type.

- Routing: Determining the optimal path for products to move through the warehouse, from receiving to shipping.

- Put-away: Placing received inventory into designated storage locations, which can impact sorting efficiency later in the process.

- Picking: Retrieving items from storage to fulfill specific orders, often grouped by factors like shipping method or destination.

- Packing: Preparing orders for shipment, which may involve sorting items based on fragility, size, or special handling needs.

Proper sorting directly impacts several key aspects of fulfillment performance:

- Delivery speed: Efficient sorting processes ensure orders are quickly routed to the correct shipping stations, reducing overall fulfillment time.

- Operational costs: Streamlined sorting reduces the time and labor required to process each order, lowering costs per shipment.

- Order accuracy: Effective sorting minimizes the risk of orders being shipped with incorrect items or to the wrong destination.

- Customer experience: By enabling faster, more accurate deliveries, sorting contributes to higher customer satisfaction and loyalty.

Sorting vs. general warehouse operations

While sorting is a critical component of warehouse operations, it’s important to distinguish it from other processes in the fulfillment flow. Receiving, storing, picking, and packing all involve the movement of goods, but sorting specifically focuses on grouping and routing items based on predefined criteria.

That said, sorting doesn’t just happen at one isolated point in the fulfillment process. It occurs at multiple stages, often in different forms:

- Inbound sorting: Organizing received inventory based on storage location, product type, or other factors to optimize put-away.

- Order sorting: Grouping picked items based on factors like shipping method, carrier, or destination to streamline packing and shipping.

- Outbound sorting: Routing packed orders to the appropriate shipping stations or carriers based on service level or destination.

When sorting errors occur, the impact can ripple through the entire fulfillment process. For example:

❌ If inbound sorting is inaccurate, items may be stored in the wrong locations, leading to slower picking times and potential stockouts.

❌ If order sorting is incorrect, packages may be sent to the wrong shipping station, resulting in delays or misrouted shipments.

❌ If outbound sorting is wrong, orders may be handed off to the wrong carriers or sent to incorrect destinations, frustrating customers and requiring costly re-shipments.

On the other hand, when sorting is optimized at each stage, it creates a virtuous cycle of efficiency:

✅ Accurate inbound sorting means items are stored in the most accessible locations, streamlining picking later on.

✅ Precise order sorting ensures that packers can quickly and accurately assemble orders, reducing the risk of errors.

✅ Efficient outbound sorting minimizes handling time and gets packages on the road faster, speeding up delivery to the end customer.

By understanding how sorting impacts each phase of fulfillment, you can develop targeted strategies for improvement that prevent bottlenecks and keep orders flowing smoothly.

The evolution of warehouse sorting

In the early days of warehousing, sorting was an entirely manual process. Workers would physically move items from one area to another, relying on memory, paper lists, or simple visual cues to determine where each product should go. While this approach was adequate for small operations with limited SKUs, it quickly became unsustainable as order volumes grew and product catalogs expanded.

As technology advanced, warehouses began to adopt semi-automated sorting systems to improve efficiency and accuracy. Conveyor belts, scanners, and simple machine vision systems allowed workers to sort items more quickly and with fewer errors. However, these systems still required significant human intervention and were often limited in their flexibility and scalability.

In recent years, the rise of fully automated sorting solutions has transformed the landscape of warehouse operations. Advanced technologies like high-speed sortation machines, robotic systems, and artificial intelligence can now handle even the most complex sorting tasks with minimal human involvement. These systems can process thousands of items per hour, adapt to changing product mixes, and make real-time decisions based on vast amounts of data.

As ecommerce continues to grow and evolve, warehouse sorting will continue to advance. The most successful fulfillment operations will be those that can stay ahead of the curve, adopting new technologies and strategies to meet the ever-changing demands of the market. By understanding the key trends and best practices shaping the industry today, you can position your warehouse sorting operations for success in the years to come.

5 common warehouse sorting methods

Warehouse sorting methods can be categorized based on the level of automation and technology involved. The right approach depends on various factors such as order volume, product mix, available budget, and growth trajectory.

Here are some of the most popular sorting methods that your brand could use in your warehouse.

1. Manual sorting

Manual sorting involves human workers physically organizing items into designated bins, shelves, or staging areas.

This method requires minimal initial investment and offers high flexibility, making it easy to implement for small-scale operations. However, manual sorting is labor-intensive, prone to human error, and can be challenging to scale as order volumes grow. It is also slower compared to automated methods, which can impact overall throughput.

Manual sorting is most suitable for small businesses with limited budgets, complex or fragile items that require delicate handling, and operations with lower order volumes.

2. Semi-automated sorting

Semi-automated sorting systems combine human decision-making with mechanical assistance, such as conveyor belts and barcode scanners.

This approach offers increased throughput and reduces physical strain on workers while still requiring a moderate investment. Employees work alongside the equipment, scanning items and making decisions based on the information provided by the system.

But semi-automated sorting still requires significant labor and has maintenance needs and space requirements to consider. This method is well-suited for mid-sized ecommerce operations looking to improve efficiency without fully automating their processes.

3. Fully automated sorting

Fully automated sorting involves advanced technologies like tilt-tray sorters, cross-belt systems, and robotic sorting.

These systems require a significant upfront investment, but offer long-term labor savings and high accuracy rates. Automated sorters can process a large number of items quickly and efficiently, reducing the need for manual intervention – though these systems come with maintenance considerations and may require extensive integration with existing warehouse management systems (WMS).

Implementing fully automated sorting can be challenging, but it is an excellent option for high-volume operations looking to maximize throughput and minimize human error.

4. Hybrid solutions

Hybrid sorting solutions combine manual and automated processes to provide flexibility and scalability.

By strategically implementing automation for certain products or processes, businesses can optimize their operations while still being able to handle exceptions or unique requirements manually. This approach is particularly useful during seasonal peaks and valleys, allowing warehouses to adapt to changing order volumes.

When considering a hybrid solution, it is essential to determine which products should go through automated sorting and which require manual handling. As a business grows, it can gradually transition from manual to more automated systems, ensuring a smooth and cost-effective evolution of their sorting processes.

5. Specialized sorting for unique products

Some products require specialized sorting due to their unique characteristics or handling requirements.

- Temperature-controlled items, such as refrigerated or frozen goods, need to be sorted in a manner that maintains their integrity and complies with food safety regulations.

- Fragile, oversized, or high-value merchandise may require additional padding, secure packaging, and separate handling to prevent damage during the sorting process.

- Hazardous materials or products with strict regulatory requirements also demand specific sorting protocols and infrastructure to ensure compliance and safety.

Specialized sorting solutions often involve dedicated areas within the warehouse, equipped with the necessary temperature control, protective materials, and trained staff to handle these unique products effectively.

Common warehouse sorting challenges to overcome

Warehouse sorting is a critical process that can significantly impact the efficiency and accuracy of order fulfillment. However, it’s not without its challenges; ecommerce businesses often face several common obstacles that can hinder their sorting operations, leading to delays, errors, and increased costs.

👷 Managing labor shortages and turnover

One of the most significant challenges in warehouse sorting is maintaining a stable and skilled workforce. High turnover rates and labor shortages can lead to inconsistent performance and increased training costs.

To mitigate this issue, consider implementing strategies for recruiting, training, and retaining sorting staff. This may include offering competitive wages, providing opportunities for growth and development, and creating a positive work environment.

Additionally, investing in ergonomic improvements can help reduce physical strain on workers, leading to higher job satisfaction and lower turnover rates. This may involve installing anti-fatigue mats, providing adjustable workstations, or using assistive devices for lifting and moving heavy items.

📦 Dealing with space constraints

As ecommerce businesses grow, they often face the challenge of managing increased order volumes within limited warehouse space. This can lead to cramped and inefficient sorting areas that hinder productivity.

Consider implementing space-saving solutions such as vertical storage and sorting systems that utilize overhead space. Reconfiguring your warehouse layout can also help maximize efficiency without requiring a physical expansion. This may involve creating dedicated sorting zones, optimizing pick paths, or installing mezzanine levels to add sorting capacity within your existing facility.

👕 Handling product diversity challenges

Ecommerce businesses often deal with a wide range of product types, sizes, and handling requirements, which can complicate the sorting process.

To streamline operations, you could implement zoning strategies that group similar items together for more efficient sorting. This may involve creating separate areas for small, medium, and large items or grouping products by their packaging requirements.

Developing standardized processes that accommodate product diversity can also help ensure consistency and accuracy in sorting. Create specific handling guidelines for fragile or high-value items, using appropriate packaging materials, and providing clear labeling and instructions for each product type, so processes are more consistent.

🔌 Troubleshooting technology integration issues

Implementing new sorting technologies can bring significant benefits, but it can also present challenges when integrating with existing systems. Common issues may include compatibility problems with your warehouse management system (WMS), data synchronization errors, or hardware malfunctions.

To minimize disruptions, you could adopt a phased implementation approach that allows for thorough testing and gradual rollout of new technologies. This can help identify and resolve issues before they impact your entire operation.

Additionally, ensure that you have a clear contingency plan in place for technology failures or outages, including manual sorting procedures and backup systems.

The benefits of effective warehouse sorting

Effective warehouse sorting is not just a necessary operational task; it directly impacts key business metrics and can provide a significant competitive advantage. By optimizing sorting processes, ecommerce brands can:

💰 Reduce shipping costs through strategic sorting

Strategic sorting can help reduce shipping costs in several ways. By sorting orders based on carrier, service level, and destination, businesses can consolidate shipments and take advantage of bulk discounts.

This is particularly effective when using regional sort centers or cross-docking operations, where orders from multiple origins can be combined into full truckloads for more efficient transportation.

For example, ShipBob’s regional sort centers allow for zone skipping, where packages are sorted and consolidated before being handed off to last-mile carriers. This can significantly reduce shipping costs compared to sending individual packages directly from the fulfillment center.

🚚 Improve delivery speed with efficient sortation

Efficient warehouse sorting is critical for getting orders to customers quickly. Streamlining the sorting process and minimizing bottlenecks enables businesses can reduce the time between order placement and shipment. This is particularly important for time-sensitive orders or customers who expect fast delivery as a standard service.

One way to improve sorting efficiency is by prioritizing orders based on delivery deadlines. If businesses identify and sort urgent orders first, they can ensure that these packages are processed and shipped as quickly as possible – which can be a significant differentiator in competitive markets where customers value speed and reliability.

🎯 Enhance inventory accuracy and control

Effective warehouse sorting can also improve inventory accuracy and control, since incorporating verification steps (such as checking for damaged items, incorrect quantities, or mismatched SKUs) into the sorting process lets businesses catch errors or discrepancies before they reach customers.

Accurate sorting also helps maintain real-time inventory visibility. When items are sorted and scanned correctly, the warehouse management system can provide up-to-date information on stock levels and locations. This data is critical for making informed decisions about reordering, inventory allocation, and demand forecasting.

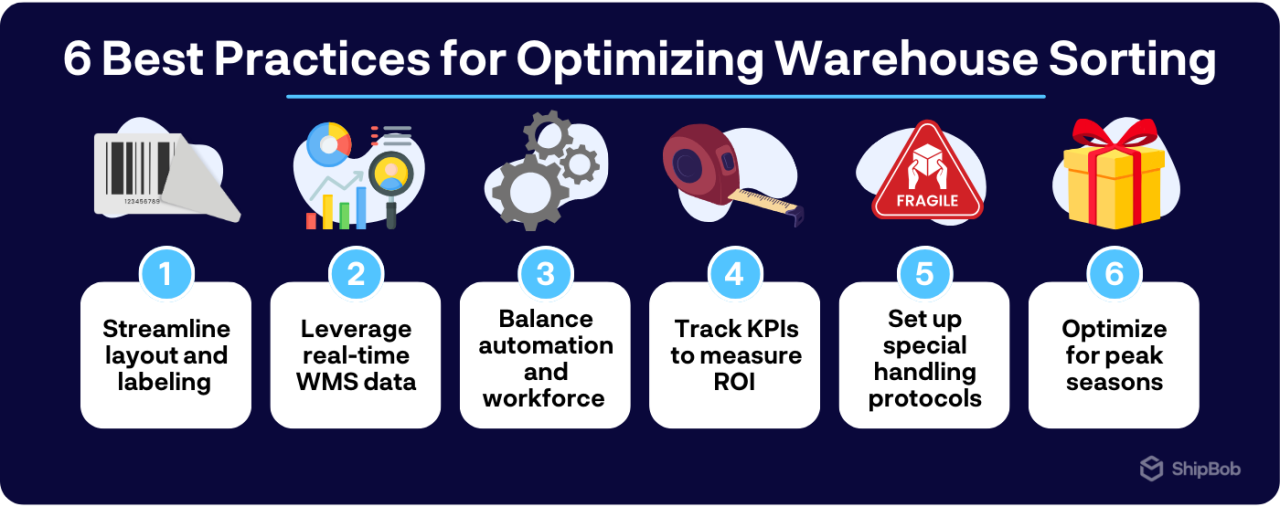

6 best practices for optimizing warehouse sorting

Optimizing warehouse sorting is an ongoing process that requires continuous assessment and improvement. Try using these best practices, businesses to create a comprehensive strategy that maximizes efficiency, accuracy, and flexibility.

1. Streamline layout and labeling

The physical setup of your sorting area can have a significant impact on efficiency. Arranging workstations, equipment, and inventory in a logical flow can minimize unnecessary movement and reduce the risk of errors, so consider creating designated zones for different product types, order priorities, or shipping methods.

Clear labeling is also essential for streamlining the sorting process. Implementing consistent, easy-to-read labels with barcodes or color-coding helps workers quickly identify and sort items correctly (which is particularly important in high-volume operations where speed and accuracy are critical).

2. Leverage real-time data from a WMS

A warehouse management system (WMS) is a powerful tool for optimizing sorting operations. It provides real-time data on inventory levels, order statuses, and worker productivity, which enables brands to quickly identify bottlenecks and opportunities for improvement.

Some key metrics to track include:

- Sorting rate: The number of items sorted per hour or shift.

- Accuracy rate: The percentage of orders sorted without errors.

- Throughput: The total volume of orders processed over a given period.

- Labor utilization: The percentage of available labor hours used for sorting tasks.

By analyzing this data, businesses can make informed decisions about staffing levels, equipment investments, and process changes.

3. Balance automation with a flexible workforce

While automation can significantly improve sorting efficiency, it’s important to strike a balance with manual processes. Fully automated systems can be expensive and inflexible, while purely manual sorting may not be able to keep up with growing order volumes.

One strategy is to automate high-volume, repetitive tasks while keeping a flexible workforce for more complex or variable sorting needs. This allows businesses to scale up or down quickly based on demand fluctuations.

Cross-training employees is also critical for maintaining flexibility. By ensuring that workers can handle multiple sorting tasks, businesses can adapt to changes in order mix or staffing levels without sacrificing efficiency.

4. Track KPIs and measure ROI

To justify investments in sorting optimization, it’s important to track key performance indicators (KPIs) and measure return on investment (ROI). Some important metrics to consider are:

- Cost per unit sorted

- Labor cost per order

- Sorting accuracy rate

- Order cycle time

- Inventory turnover rate

By setting benchmarks and tracking progress over time, businesses can quantify the impact of sorting improvements. This data can also be used to build a business case for further investments in technology or process changes.

5. Implement special handling protocols for unique products

Many ecommerce businesses deal with products that require special handling during the sorting process. This can include items that are fragile, oversized, temperature-sensitive, or subject to regulatory requirements.

To ensure that these products are sorted correctly and efficiently, it’s important to develop clear protocols and train staff accordingly. This may involve creating dedicated sorting areas with appropriate equipment, such as refrigerated conveyor belts or reinforced packaging stations.

Integrating these special handling requirements into the overall sorting workflow is also critical. Implementing a WMS to flag orders with unique needs, businesses can ensure that these items are routed to the appropriate sorting stations without disrupting the overall process.

6. Optimize for peak seasons and volume fluctuations

Ecommerce businesses often face significant fluctuations in order volume, particularly during peak shopping seasons. To maintain sorting efficiency during these periods, it’s important to have a flexible strategy that can scale up or down quickly.

One approach is to use a combination of in-house and outsourced sorting capacity. By partnering with an expert supply chain and fulfillment partner like ShipBob, businesses can tap into a network of fulfillment centers and sort centers that can absorb excess volume during peak periods. This allows businesses to maintain fast, reliable sorting without investing in additional infrastructure or staffing.

Forecasting and planning are also critical for peak season success. It’s important to analyze historical data and sales projections, so that you can anticipate sorting volume and adjust staffing and equipment accordingly (e.g., by adding temporary labor, extending shifts, or reconfiguring the sorting area to accommodate higher throughput).

How to use analytics and data-driven sorting for continuous improvement

Data is a powerful tool for driving continuous improvement in warehouse sorting operations. By collecting and analyzing key metrics, businesses can identify opportunities for optimization and measure the impact of changes over time.

Key sorting metrics to monitor

To get a comprehensive view of sorting performance, businesses should track a range of metrics across different aspects of the operation. Some key metrics to monitor include:

- Sorting accuracy: The percentage of orders sorted without errors, such as incorrect items or quantities. This metric is critical for ensuring customer satisfaction and reducing returns.

- Sorting speed: The average number of items or orders sorted per hour or shift. This metric helps assess the overall efficiency of the sorting process and identify bottlenecks.

- Labor productivity: The number of orders sorted per labor hour. This metric helps optimize staffing levels and identify opportunities for process improvements.

- Cost per unit: The total cost of sorting divided by the number of units processed. This metric helps assess the overall cost-effectiveness of the sorting operation and identify areas for cost reduction.

- Order cycle time: The average time from when an order is received to when it is shipped. This metric helps assess the overall speed and reliability of the fulfillment process, including sorting.

- Inventory accuracy: The percentage of physical inventory that matches the records in the warehouse management system. This metric is critical for ensuring that the right items are available for sorting and reducing stockouts or overstocks.

Turning sorting data into actionable insights

Collecting data is only the first step in using analytics to drive sorting improvements. To turn this data into actionable insights, businesses need to have a structured process for analysis and decision-making.

One approach is to use a continuous improvement framework like DMAIC (Define, Measure, Analyze, Improve, Control). This involves:

- Defining the problem or opportunity based on the data collected.

- Measuring the current state of the sorting process using key metrics.

- Analyzing the data to identify root causes and potential solutions.

- Improving the process by implementing changes and measuring their impact.

- Controlling the process to ensure that improvements are sustained over time.

For example, if the data shows that sorting accuracy is below target, the team might:

- Define the problem as “Sorting accuracy is currently 95%, below our target of 99%.”

- Measure the current accuracy rate across different shifts, products, and workers.

- Analyze the data to identify potential causes, such as unclear labeling, inadequate training, or equipment malfunctions.

- Improve the process by implementing changes, such as updating labels, providing additional training, or repairing equipment.

- Control the process by setting up ongoing monitoring and audits to ensure that the improvements are sustained.

With this kind of structured approach to data analysis and continuous improvement, businesses can make informed decisions that drive meaningful changes in their sorting operations.

Scaling your warehouse sorting for peak seasons

Peak seasons, such as holidays or promotional events, can put significant strain on warehouse sorting operations. To maintain efficiency and customer satisfaction during these periods, businesses need to have a proactive strategy for scaling their sorting capacity.

Planning for predictable volume spikes

Many peak seasons, such as the holiday shopping rush, are predictable based on historical data and industry trends. That’s why it’s important to analyze past performance and forecast future demand, so businesses can create a plan for scaling their sorting operations in advance.

Some key elements of a peak season sorting plan include:

- Inventory positioning: Ensuring that the right products are in the right locations to minimize sorting time and maximize throughput. This may involve pre-sorting high-demand items or positioning them closer to packing stations.

- Staffing: Determining the optimal number of workers needed to handle the expected volume, and creating a plan for recruiting, training, and scheduling temporary staff.

- Equipment and space: Assessing whether additional sorting equipment or space will be needed to handle the increased volume, and making arrangements for rental or temporary setup.

- Carrier relationships: Communicating with carriers to ensure that they have the capacity to handle the expected volume and negotiating any necessary rate or service level agreements.

Having this kind of comprehensive plan in advance helps businesses minimize disruptions and maintain high levels of service during peak seasons.

Responding to unexpected sorting demands

While many peak seasons are predictable, businesses also need to be prepared for unexpected spikes in demand. Whether it’s because of a viral product, a competitor going out of stock, or a natural disaster disrupting the supply chain, make sure your operations are flexible and scalable enough to handle surges.

Some strategies for achieving this include:

- Cross-training: Ensuring that workers are trained to handle multiple sorting tasks, so that they can be redeployed quickly as needed.

- Temporary space: Having agreements in place with temporary warehouse providers or 3PLs to quickly secure additional sorting space if needed.

- Outsourcing: Partnering with an expert provider like ShipBob that can provide on-demand sorting capacity and expertise.

- Inventory management: Using real-time inventory tracking to quickly identify and prioritize high-demand items for sorting.

Want to outsource your warehouse sorting to a leading fulfillment partner?

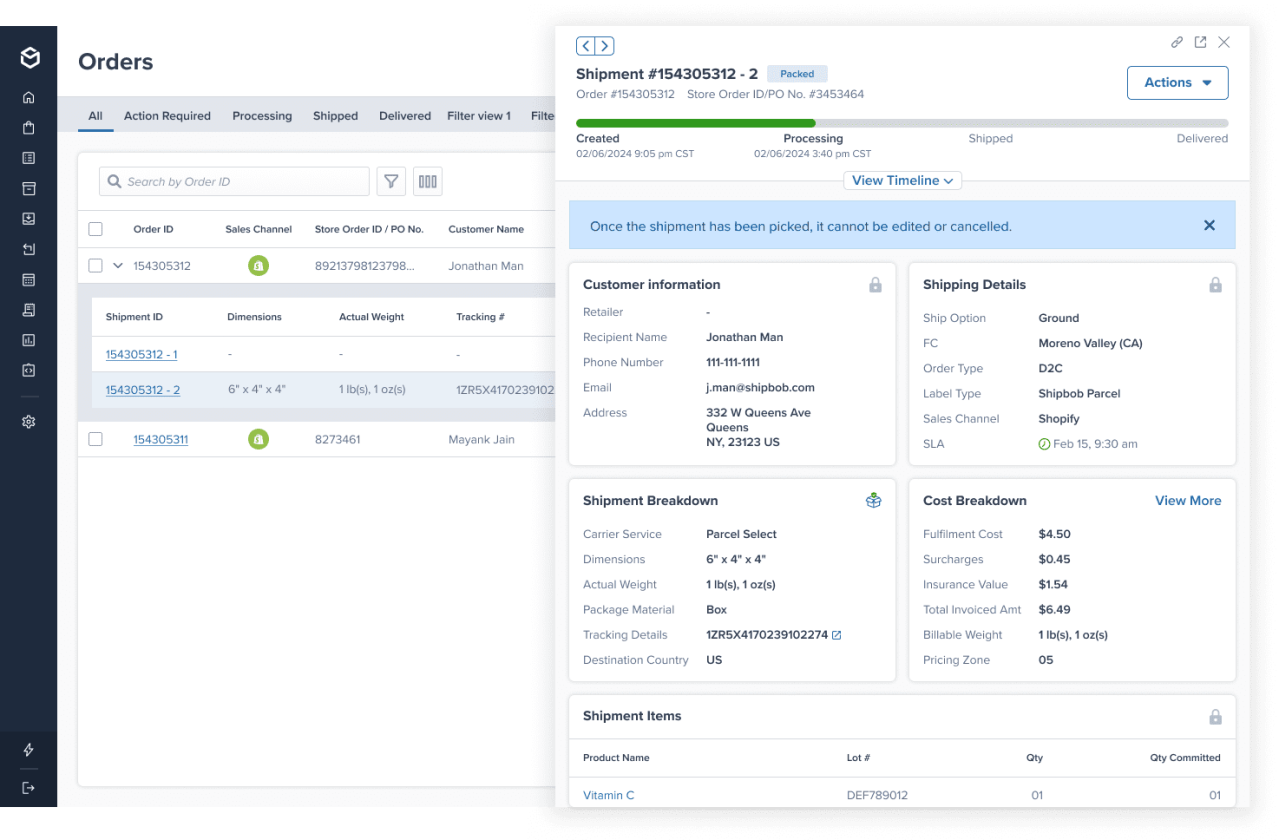

At ShipBob, we understand that efficient sorting is the heartbeat of high-performing fulfillment. That’s why we’ve built a global fulfillment network powered by advanced warehouse technology and real-time data – so ecommerce brands like yours can deliver fast, accurate orders at scale.

From inbound inventory routing to outbound shipping sortation, ShipBob’s proprietary WMS optimizes every stage of the sorting process. Our facilities are equipped to handle everything from high-volume DTC orders to custom B2B workflows, including specialized sorting for fragile, regulated, or temperature-sensitive products.

“We also get access to ShipBob Logistics, which includes ShipBob’s outbound sortation solution and has saved us time and money thanks to their economies of scale.

We don’t have to sort DTC parcels manually by carrier anymore; all we have to do is label orders, and every day, ShipBob picks up gaylords of unsorted packages directly from our warehouse. That same day, ShipBob brings them back to one of their sortation facilities, where their automated sorters get each package in a gaylord for the right carrier, and then the carriers come pick them up for final-mile delivery.

Because ShipBob has built out a large volume and density of outbound orders in the regions they operate in, carriers will come to their sites for pickups more frequently than what they’d do for a single brand. This means that our orders are getting picked up by carriers faster, which minimizes lead times.

It also enables zone skipping, so we’re shipping orders from lower zones to save money while still getting orders to customers in a few days.”

Tim Poyer, VP of Operations and Logistics at Elwood Clothing

Need to scale during peak seasons or flash sales? Our flexible fulfillment infrastructure dynamically adjusts to your volume, helping you maintain speed and accuracy without overextending your internal resources. And with full visibility through your ShipBob dashboard, you stay in control of your inventory and operations — without needing to manage sorting or fulfillment manually.

Let us handle the complexity of warehouse sorting so you can focus on growing your business. Click the button below to get in touch with our team.

Warehouse sorting FAQs

Here are answers to some of the most common questions about warehouse sorting.

What role does warehouse sorting play in broader ecommerce logistics?

Warehouse sorting acts as the connective tissue between various fulfillment processes, directly impacting overall efficiency and customer satisfaction.

Effective sorting ensures accurate inventory management, timely order processing, and cost-effective shipping.

By streamlining the flow of goods from receiving to shipping, proper sorting contributes to faster, more precise deliveries that meet customer expectations.

How do I decide between manual, semi-automated, or fully automated sortation in warehouse operations?

Choosing between manual, semi-automated, and fully automated sorting depends on factors such as order volume, product characteristics, budget, and growth trajectory. Consider the ROI of each option based on your specific needs.

Manual sorting may suffice for small operations with limited SKUs, while high-volume businesses with diverse product lines may require automation. A phased approach – gradually implementing automation as your business scales – can provide the best balance of efficiency and cost-effectiveness.

How can I reduce labor costs while still improving sorting speed and accuracy?

Strategically automating high-volume sorting tasks can significantly reduce labor costs without sacrificing speed or accuracy. Identify repetitive, time-consuming processes that can be streamlined through technology. Additionally, optimize your workforce through cross-training initiatives and proactive planning for peak periods. Improved facility layout and standardized processes can further boost productivity, allowing your staff to work smarter, not harder.

What if I have temperature-controlled or specialized items that need unique handling?

Establish dedicated sorting areas equipped with the necessary infrastructure to maintain product integrity. This may include temperature-controlled zones, specialized racking, and handling equipment.

Ensure your staff receives comprehensive training on the unique requirements of these items, such as temperature monitoring, expiration date tracking, and fragile item handling.

Stay current with relevant regulations and compliance standards to avoid costly mistakes.

How can warehouse sorting become a competitive advantage for my ecommerce brand?

Efficient warehouse sorting directly translates to faster delivery times, higher order accuracy, and exceptional customer service. By prioritizing sorting optimization, you can:

- Significantly reduce processing times, enabling you to offer expedited shipping options that set you apart from competitors.

- Minimize returns and customer complaints, protecting your brand reputation.

- Create the capacity to expand your product offerings and enter new markets ahead of the competition.

What technology investments provide the best ROI for warehouse sorting?

The technology that delivers the best ROI for warehouse sorting varies based on your unique operational needs. Generally, a robust warehouse management system (WMS) with features specifically designed to enhance sorting efficiency is a smart investment. Automated sorting equipment, such as conveyor systems, pick-to-light devices, and sortation machines, can provide significant returns for high-volume operations.

Does ShipBob offer flexible sorting solutions for high-volume or peak seasons?

Yes, ShipBob provides adaptable sorting solutions to accommodate fluctuating order volumes and peak season demands.

Our fulfillment network is strategically designed to scale sorting capacity as needed, ensuring your orders are processed efficiently – even during the busiest times. We leverage advanced technology to dynamically route orders based on real-time inventory availability, carrier performance, and delivery deadlines. Our software also provides complete visibility into the sorting process, giving you peace of mind during critical sales periods.