Verified & Reviewed

Published on October 20, 2025 Written By Rachel Hand

Published on October 20, 2025 Written By Rachel Hand

Subscribe for More

In warehouse operations, aisle layout is more than a matter of convenience; it’s a key driver of efficiency, safety, and scalability.

Aisle width directly affects how quickly orders are picked, how much inventory you can store, and how smoothly equipment moves through your space.

But designing the right aisle configuration isn’t always straightforward. It takes balancing racking systems, product sizes, traffic flow, and future growth.

In this guide, we’ll show you how smart aisle planning can transform your very own warehouse performance – and why picking the right WMS is a game changer.

What is a warehouse aisle?

A warehouse aisle is a designated corridor or space between parallel rows of shelving or racking.

Warehouse aisles are a critical component of any fulfillment center, because they:

1. Serve as the primary pathways for accessing stored inventory, and

2. Facilitate the efficient movement of goods and personnel throughout the facility.

While the terms “aisle” and “walkway” are often used interchangeably in everyday conversation, warehouse aisles serve a more specific purpose than walkways. Aisles must be strategically designed to accommodate the unique needs of material handling equipment, such as forklifts and pallet jacks, which are essential for moving products in and out of storage locations.

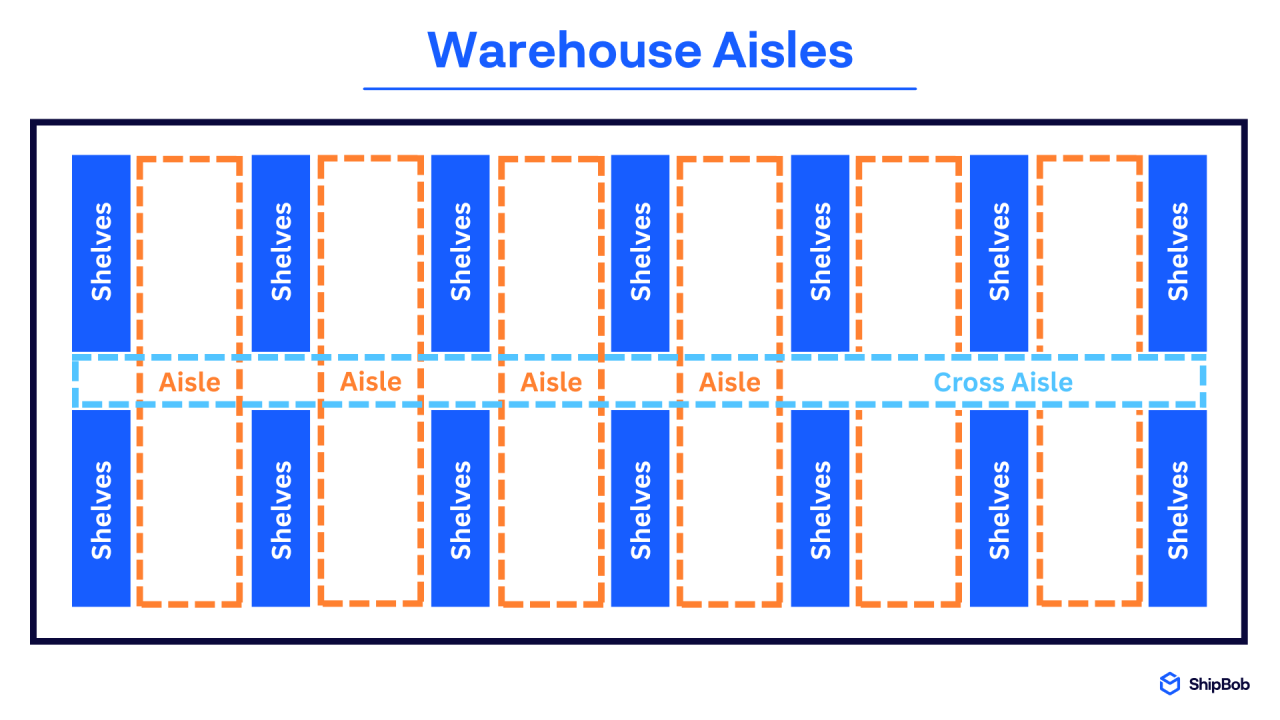

There are several types of warehouse aisles, each playing a specific role in the overall functionality of the facility:

- Picking aisles: These are the primary aisles that pickers navigate through to retrieve products for customer orders. Picking aisles are typically narrower than other aisle types to maximize storage density, but remain wide enough to allow for efficient product retrieval.

- Cross aisles: Running perpendicular to picking aisles, cross aisles provide access to different sections of the warehouse and allow for more efficient traffic flow. They are generally wider than picking aisles to accommodate two-way traffic and the turning radius of material handling equipment.

- Staging areas: Located at the ends of picking aisles or along cross aisles, staging areas serve as temporary holding spaces for products that have been picked and are awaiting final packing and shipping.

Here is a visual of a typical warehouse aisle layout:

This grid-like configuration allows workers and equipment to efficiently navigate the facility, accessing any given storage location with minimal travel time and maximum ease of movement.

Why warehouse aisle optimization matters

Properly designed warehouse aisles are more than just empty spaces between shelves; they are the arteries of your ecommerce fulfillment operations, directly impacting everything from worker productivity to inventory accuracy to order turnaround times. By optimizing your aisle configurations, you can unlock significant gains in efficiency and cost savings.

The difference between a well-optimized warehouse layout and a poorly designed one can be staggering. When aisles are too narrow, too wide, or improperly placed, it can lead to wasted space, increased travel time for workers, and even safety hazards.

On the flip side, a thoughtfully designed aisle system can help you:

- Maximize storage capacity: Striking the right balance between aisle width and storage density lets you make the most of your available space without sacrificing accessibility.

- Improve picking efficiency: Optimized aisle layouts minimize the distance workers must travel between picks, reducing fatigue and increasing productivity.

- Reduce labor costs: When workers can navigate the warehouse more efficiently, you can accomplish more with fewer labor hours, directly impacting your bottom line.

- Enhance inventory accuracy: Well-organized aisles with clear labeling and logical product placement make it easier for workers to locate and retrieve the right items, reducing picking errors.

- Speed up order fulfillment: By streamlining the picking process and minimizing congestion, optimized aisles help you get orders out the door faster, improving customer satisfaction.

Ultimately, aisle optimization is about more than maximizing space utilization – it’s a strategic decision that directly impacts your ability to serve customers effectively and efficiently. Taking a data-driven approach to aisle design means you can create a warehouse layout that supports your unique operational needs and sets you up for long-term success.

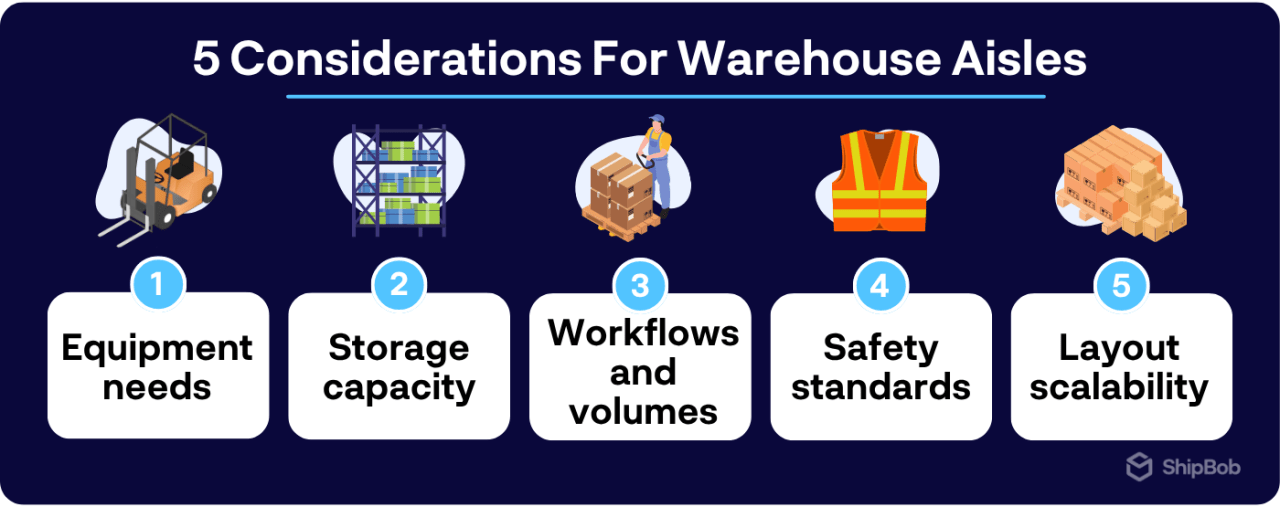

5 factors to consider when determining warehouse aisle width and length

It seems like a simple question: how long and wide should your aisles be? But it impacts more than you think, and different businesses will have different optimal configurations based on their unique needs. So before you make a quick or arbitrary decision on aisle size, make sure you consider these factors.

1. Forklift turning radius and equipment requirements

Different equipment types require specific clearances. Counterbalance forklifts, reach trucks, and order pickers all have different turning radii that must be accounted for when designing aisle widths.

To calculate minimum width requirements, start with the equipment specifications and add extra space for operator error and safe maneuvering. A typical counterbalance forklift, for example, requires a minimum aisle width of 12 feet to navigate safely.

2. Storage capacity and SKU variety

Product dimensions and storage methods also affect aisle width decisions. Wider aisles generally mean lower overall storage density, so businesses with limited space may opt for narrower configurations.

However, if you stock a wide variety of SKUs with different sizes and shapes, wider aisles may be necessary to accommodate diverse storage requirements. It’s all about striking the right balance between storage capacity and operational accessibility.

3. Workflow requirements and order volume

Your picking methods and order volume should also factor into aisle width decisions. Batch picking, for example, requires more aisle space than single-order picking to accommodate multiple pickers working simultaneously.

High-volume operations may also require wider aisles to prevent congestion and bottlenecks, especially if you have mutiple pickers and restockers working in the same areas. Analyzing traffic patterns can help determine the optimal aisle widths for your specific workflow.

4. Safety regulations and compliance standards

Aisle width is also a safety consideration. OSHA guidelines and international standards specify minimum clearances for emergency access and evacuation. Aisles must be wide enough to accommodate swift exits in case of a fire or other emergency. Facilities with pedestrian traffic must also ensure ADA compliance. Failing to meet these standards can result in costly fines and legal liabilities.

5. Layout design and future scalability

Finally, consider your current layout and future growth projections when determining aisle widths.

Wide aisle configurations offer more flexibility and require less specialized equipment, while narrow and very narrow aisle (VNA) setups can significantly increase storage density. However, VNA configurations require specialized equipment and technology infrastructure, so they may not be suitable for every operation.

Use a modular design approach to ensure your aisle configuration can adapt as your business needs change.

Calculating warehouse aisle widths by configuration

Determining the optimal aisle width for your warehouse is a critical decision that directly impacts storage capacity, picking efficiency, and overall operational flow. While there’s no one-size-fits-all solution, understanding the standard measurements for different configurations can help you make an informed choice based on your unique business needs.

To help you navigate this complex landscape, here’s a quick guide to the most common aisle width configurations, along with specific recommendations for various equipment types and operational scenarios.

Standard wide aisle configurations

For many warehouses, wide aisle configurations are the default choice. With typical measurements ranging from 10 to 12 feet, these layouts provide ample space for maneuvering standard forklifts and other common equipment.

The main benefit of wide aisles is their flexibility: they can accommodate a variety of product sizes and storage methods, and they don’t require specialized equipment or extensive operator training.

However, this flexibility comes at a cost. Wide aisles consume a significant amount of floor space, reducing overall storage density. They’re best suited for warehouses with lower inventory levels, larger product dimensions, or less predictable order patterns. If your business deals primarily with bulky items or requires frequent access to all stored products, wide aisles may be the way to go.

Narrow aisle configurations

For businesses looking to maximize storage capacity without sacrificing too much in terms of accessibility, narrow aisle configurations offer an attractive middle ground.

With widths typically ranging from 8 to 10 feet, these layouts allow for a significant increase in storage density while still accommodating specialized equipment like reach trucks and order pickers.

Transitioning from wide to narrow aisles does require some operational adjustments – for instance, your team will need to be trained on the new equipment and you may need to invest in updated safety systems and traffic management protocols – but for many businesses, the efficiency gains and space savings more than justify these upfront costs.

When considering a narrow aisle configuration:

- Carefully evaluate your ROI potential.

- Analyze your current storage utilization and project how much additional capacity you could gain by narrowing your aisles.

- Weigh those benefits against the costs of new equipment, training, and any necessary layout changes.

With careful planning and execution, narrow aisles can be a game-changer for growing warehouses.

Very narrow aisle (VNA) configurations

To achieve the most storage density, very narrow aisle (VNA) configurations are the way to go. With typical widths of just 5 to 7 feet, these layouts can increase storage capacity by up to 50% compared to standard wide aisle designs.

However, this remarkable space efficiency comes with some significant trade-offs. VNA configurations require highly specialized equipment, such as turret trucks and side-loading forklifts, which can be expensive to purchase and maintain. Operators need extensive training to navigate these ultra-narrow spaces safely and efficiently, and the risk of accidents and product damage is higher than with wider configurations.

VNA layouts also require a substantial technology infrastructure to support their complex operations. You’ll need a robust warehouse management system (WMS) to optimize picking routes and inventory placement, as well as advanced safety systems to prevent collisions and other accidents.

Given these challenges, VNA configurations are best suited for businesses with high-volume, high-density storage needs and relatively predictable order patterns. If your warehouse deals primarily with small, uniform products and can justify the upfront investment in specialized equipment and technology, VNA could be a powerful tool for maximizing your space utilization.

How to optimize your warehouse aisles for operational excellence

Once you’ve determined the optimal aisle configuration for your warehouse, the work doesn’t stop there. Continuously optimizing your aisle layout and inventory placement is crucial for maintaining peak operational efficiency.

Here are some best practices for to help ensure your warehouse aisles are always working hard for your business.

Slotting strategies and inventory placement

One of the most effective ways to optimize your warehouse aisles is through strategic slotting and inventory placement. By analyzing product velocity and order patterns, you can position your fastest-moving SKUs in the most accessible locations, reducing travel time for pickers and improving overall throughput.

Techniques like ABC analysis can help you prioritize your inventory based on demand, ensuring that your most popular products are always within easy reach. When you group similar products together and place them in logical sequences along your aisles, you can further streamline your picking processes and minimize wasted motion.

Integrating scanning or RFID systems

Integrating advanced scanning or RFID systems into your aisle operations can take your efficiency to the next level. Use barcode scanners or RFID readers to track inventory movement in real-time, and simultaneously improve accuracy and reduce the risk of errors at every stage of the fulfillment process.

These technologies seamlessly integrate with your broader warehouse management system (WMS), enabling you to maintain a precise, up-to-the-minute view of your inventory levels and locations. With the right scanning or RFID setup, you can virtually eliminate manual data entry and streamline your picking workflows for maximum speed and accuracy.

Dynamic reconfiguration for seasonal demands

For many businesses, demand patterns can shift dramatically from season to season. To keep your aisles clear and operations running smoothly during peak periods, it’s important to have strategies in place for dynamic reconfiguration.

Modular racking systems and flexible layout designs allow you to quickly adjust your aisle configurations to accommodate changing inventory levels and order volumes. Analyzing historical data can also help you predict when these layout changes will be necessary, allowing you to stay ahead of potential bottlenecks and congestion.

Successful seasonal adaptations require careful planning and coordination across your entire warehouse operation. But with the right approach, you can ensure that your aisles are always optimized for the unique demands of each season.

Warehouse management systems and real-time analytics

Ultimately, optimizing your warehouse aisles requires a comprehensive, data-driven approach. That’s where advanced warehouse management systems (WMS) like ShipBob’s come in.

With a powerful WMS in place, you can leverage real-time analytics to identify inefficiencies and improvement opportunities at every level of your operation. By analyzing picking routes, travel times, and inventory turnover rates, you can pinpoint exactly where your aisle configuration may be holding you back – and take targeted steps to address those issues.

ShipBob’s WMS, for example, uses advanced algorithms to optimize picking routes and reduce travel time, ensuring that your pickers are always taking the most efficient path through your aisles. And with predictive analytics capabilities, you can even anticipate and prevent congestion before it occurs, keeping your aisles flowing smoothly no matter what challenges come your way.

“The hands-on onboarding from ShipBob taught us how to create efficient pick paths. Prior to ShipBob, we had our most popular products at the front. Through the implementation process we learned that if you’re commonly picking certain items, they should be stored in the back so you aren’t carrying them around while you’re picking other items. Our best sellers are at the end of the pick path now, so once we’ve picked those, we’re already back at the pack stations.”

Adam LaGesse, Global Warehousing Director at Spikeball

How to ensure safety and regulatory compliance in warehouse aisles

While optimizing your warehouse aisles for efficiency is crucial, it should never come at the expense of safety. Proper aisle design plays a significant role in preventing accidents and ensuring compliance with industry regulations.

Signage, labeling, and markings

One of the most effective ways to ensure safety in your warehouse aisles is through clear, consistent signage and labeling. Implementing a standardized color-coding system for floor markings, directional indicators, and safety signs helps employees quickly identify potential hazards and navigate the space more efficiently.

When designing your signage and labeling strategy, consider the following best practices:

- Use high-contrast colors for maximum visibility, even in low-light conditions.

- Place signs at eye level and in prominent locations near key decision points.

- Use internationally-recognized symbols and pictograms to overcome language barriers.

- Regularly inspect and maintain signs to ensure they remain legible and up-to-date.

By creating a clear visual system throughout your warehouse aisles, you can reduce the risk of accidents, improve overall efficiency, and ensure compliance with safety regulations.

Lighting, visibility, and Wi-Fi coverage

Proper lighting is another critical factor in maintaining safe and efficient warehouse aisles. Adequate illumination not only reduces the risk of accidents but also improves picking accuracy and employee productivity. When designing your lighting plan, consider the following factors:

- Ensure consistent illumination throughout the warehouse, eliminating shadows and glare.

- Use energy-efficient LED lighting to reduce costs and improve visibility.

- Implement motion-activated lighting in low-traffic areas to conserve energy.

- Regularly clean and maintain light fixtures to ensure optimal performance.

In addition to lighting, it’s important to ensure reliable Wi-Fi coverage throughout your warehouse aisles. With the increasing adoption of mobile devices and connected technologies in modern warehouses, a strong wireless infrastructure is essential for supporting real-time data collection, inventory tracking, and communication between employees.

However, the metal-heavy environment of a typical warehouse can present challenges for wireless signal propagation. To overcome these issues, consider the following strategies:

- Conduct a thorough site survey to identify potential dead zones and interference sources.

- Use high-gain antennas and strategically placed access points to ensure consistent coverage.

- Implement a mesh network architecture to provide redundancy and improve signal strength.

- Regularly monitor and optimize your wireless network to maintain peak performance.

By prioritizing lighting, visibility, and Wi-Fi coverage in your warehouse aisles, you can create a safer, more connected work environment that supports both compliance and operational efficiency.

Traffic control and congestion avoidance

Managing traffic flow is another key aspect of ensuring safety and efficiency in your warehouse aisles. With multiple employees and pieces of equipment moving through the space simultaneously, it’s essential to have clear protocols in place to prevent collisions and minimize congestion.

Consider implementing the following strategies to control traffic in your warehouse aisles:

- Establish one-way traffic flows to reduce the risk of head-on collisions.

- Use floor markings and signage to clearly designate travel lanes and directions.

- Implement speed limits and right-of-way protocols for intersections and blind corners.

- Stagger shifts and break times to minimize peak congestion periods.

- Use real-time data from your WMS to monitor traffic patterns and identify potential bottlenecks.

Outsource your warehouse optimization to ShipBob’s storage and fulfillment services

Optimizing your warehouse aisles for peak performance is a complex and ongoing challenge that requires deep expertise, advanced technology, and a commitment to continuous improvement. For many ecommerce brands, partnering with a trusted 3PL or supply chain and logistics platform like ShipBob is the key to unlocking the full potential of their warehouse operations.

With a global network of strategically located fulfillment centers, ShipBob has a proven track record of solving complex aisle configuration challenges for businesses of all sizes. By leveraging ShipBob’s expertise in warehouse layout and mapping, WMS implementation, and inventory placement, you can ensure that your products are always stored and picked in the most efficient manner possible.

“Before ShipBob, certain team members were assigned to specific brands, and whenever someone was out sick or unavailable, we were scrambling to figure out who had the knowledge to cover for them and how to get them up to speed. Now, with ShipBob WMS, everything scrupulously mapped, tracked, and monitored in the system.

I’m excited for a peak that doesn’t feel like peak, and I really think ShipBob’s WMS is going to help us get there. ShipBob WMS helped us look at our warehouse and reevaluate how it’s organized and how efficient the actual flow of our layout of the warehouse is. It’s given us a lot of insight as to what new materials we should be investing in, so that fulfillment operations will only get easier for our warehouse manager and team as we scale.”

Brian Spencer, General Manager of SMLXL

ShipBob’s state-of-the-art technology infrastructure, including its proprietary WMS, enables real-time inventory management and optimized picking routes that minimize travel time and maximize productivity. And with standardized aisle management practices across its entire fulfillment network, ShipBob ensures consistent operational excellence, no matter where your products are stored.

By outsourcing your warehouse optimization to ShipBob, you can focus on growing your business while leaving the complexities of aisle configuration and inventory management to the experts.

“Choosing ShipBob WMS to power our warehouse was the best decision I’ve ever made as a business owner. We have so many SKUs already, and we’re adding hundreds, maybe even thousands of SKUs every month, on top of growing order volumes. If we had kept using our old, patchworked approach to warehouse management and fulfillment, we would have been in a lot of trouble – we wouldn’t have been able to manage inventory or keep up with demand, let alone scale. ShipBob’s WMS allows us to do all of that. It’s been such a great solution for us.”

Tim Poyer, VP of Operations and Logistics at Elwood Clothing

For more information on how ShipBob’s WMS can help you make the most out of your space and improve your operations, click the button below to get in touch.

Warehouse aisle FAQs

Here are answers to some of the most frequently asked questions about warehouse aisles and how they impact fulfillment operations.

What are the standard warehouse aisle width guidelines I should follow?

While there are no one-size-fits-all rules for warehouse aisle widths, there are some general guidelines to follow based on your specific needs:

- For wide aisle configurations, aim for 12 feet or more to accommodate standard forklifts and allow for easy maneuvering.

- If you’re using narrow aisles, 8-10 feet is typically sufficient, but be sure to account for any specialized equipment requirements.

- Very narrow aisle (VNA) setups can go as slim as 5-7 feet, but require purpose-built equipment and robust safety protocols.

How can I prevent bottlenecks and accidents in narrow aisles?

Narrow aisles can be tricky to navigate, especially during peak periods or when multiple tasks are happening simultaneously.

Consider implementing one-way traffic flows and clearly marked lanes to reduce congestion and confusion. Schedule tasks like replenishment and cycle counts during off-peak hours to help minimize aisle blockages. Finally, make sure your team is well-versed in safety protocols and knows how to handle the specific challenges of narrow aisle environments.

Why is lighting crucial in warehouse aisles?

Proper lighting is often overlooked in warehouse design, but it plays a critical role in both safety and efficiency. Well-lit aisles help reduce picking errors by making it easier for workers to read labels and locate products; especially important in narrow, low-visibility aisle configurations.

From a safety perspective, good lighting helps prevent accidents by making it easier to spot hazards and navigate around obstacles. It also reduces eye strain and fatigue, which can lead to improved worker productivity and morale.

How does warehouse aisle width affect storage capacity?

The wider your aisles, the less space you have available for racking and shelving. Conversely, narrower aisles allow you to pack in more storage, but at the cost of reduced accessibility and maneuverability.

The key is to find the right balance for your specific needs.

If you have a large number of SKUs and need to maximize storage density, narrow or very narrow aisle configurations may be the way to go. But if you have high-volume, fast-moving products that require constant access, wider aisles may be a better choice.

What role does ShipBob play in optimizing aisle design for ecommerce brands?

ShipBob takes a data-driven approach to aisle configuration. Our proprietary warehouse management system analyzes product velocity, dimensions, and other key metrics to determine the optimal slotting strategy for each client.

We then use this information to design aisle layouts that minimize travel time and maximize picking efficiency.

But we don’t stop there; ShipBob’s WMS also optimizes picking routes in real-time, ensuring that our fulfillment associates are always taking the most efficient path through the warehouse.

How often should warehouse aisle configurations be reviewed and updated?

Warehouse aisle configurations should be reviewed on a regular basis to ensure they’re still meeting your operational needs. At a minimum, aim to assess your layout annually, or whenever you experience significant changes in your product mix, order volume, or storage requirements.

It’s also a good idea to conduct more frequent assessments if you’re experiencing issues like congestion, bottlenecks, or high error rates. These can be signs that your current aisle layout is no longer working as intended and may need to be adjusted.

What are the latest innovations in warehouse aisle management?

One of the most exciting developments in recent years has been the rise of AI-powered slotting optimization. These advanced algorithms can analyze vast amounts of data to determine the optimal product placement and aisle configuration for your facility, taking into account factors like product velocity, size, weight, and picking frequency.

Another emerging technology is flexible racking systems that allow you to quickly adjust your aisle layout as needed. These modular systems can be easily reconfigured to accommodate changes in product mix or storage requirements, without the need for major renovations or equipment purchases.