Verified & Reviewed

Published on October 27, 2025 Written By Rachel Hand

Published on October 27, 2025 Written By Rachel Hand

Subscribe for More

Whether you’re considering outsourcing logistics to a 3PL or already leverage one, their performance is always top-of-mind. You want your partner to do a great job with everything from inventory storage to fulfillment to shipping – but how do you know if they are?

The easiest way to evaluate your 3PL’s performance is to closely monitor key performance indicators (KPIs) to make sure that they’re operating to your standards.

In this post, we’ll go over the most important 3PL metrics to track, why they’re important, and how an expert fulfillment provider like ShipBob can help you improve them and optimize your logistics.

Understanding the metrics and KPIs behind 3PL performance

3PL KPIs (or key performance indicators) are vital metrics that are used to measure the performance of a 3PL company.

They give you insight into your 3PL’s operational efficiency and whether they are helping you meet your business goals.

Importance of tracking 3PL KPIs

If you trust your 3PL, you may ask yourself: why should I bother tracking any KPIs? The answer is that monitoring 3PL KPIs not only confirms how your 3PL is doing, but helps you better understand your business – and how to improve it.

Increased efficiency

When you closely monitor important KPIs like fulfillment speed, you can see whether the 3PL is fulfilling your ecommerce orders quickly.

You can use these insights to benchmark your supply chain performance against the competition and see if there’s any need or opportunity to improve efficiency. You can then work with the 3PL to make improvements in how inventory and orders are moved through the supply chain for greater efficiency.

Better cost management

Certain 3PL metrics will tell you how much you’re spending on certain supply chain areas, functions, and tasks. You can use these insights to see how you’re allocating your resources, and how closely you’re sticking to your budget.

If you see these numbers increasing or if costs are climbing too high, you can take immediate action to mitigate the issue before you end up overspending.

Improved customer satisfaction

By constantly monitoring your logistics performance, you are better prepared to improve and optimize your operations for speed and cost.

When you provide a faster, cheaper, and more seamless delivery experience without sacrificing order accuracy, you’ll delight customers and build brand loyalty that translates into more purchases.

6 key 3PL metrics and KPIs to monitor

While there are a lot of metrics you could use to understand how your 3PL is working, some are more telling than others. Here are some of the most crucial KPIs to track to evaluate your 3PL performance.

1. Order accuracy

This is a measure of how many items were shipped and delivered to your customers without any errors. These errors may include mispicks, sending the wrong quantity, shipping to the wrong destination, or a package being delivered late. Your order accuracy directly impacts customer satisfaction, so it’s important that your 3PL partner maintain extremely high OTIF rates to preserve your relationship with your customers.

ShipBob’s logistics teams, for example, run on a WMS that enforces multiple carefully designed checks and balances throughout the order fulfillment process to ensure order and shipping accuracy. This helps minimize errors, helping us maintain a 99.95% accuracy rate in fulfilling orders.

“The technology employed by ShipBob guarantees accurate deliveries to our customers. ShipBob’s warehouse management system is equipped with numerous checks and balances, minimizing the possibility of incorrect items being shipped by warehouse associates.”

Ali Shahid, COO of Our Place

2. Fulfillment speed

Your fulfillment speed is a measure of how quickly orders are picked, packed, and shipped out to your customers. It helps you understand the efficiency of a 3PL’s operations, as goods need to move seamlessly between various fulfillment processes in order to be fulfilled and shipped on time.

Higher fulfillment speeds ultimately contribute to higher on-time shipping rates and faster deliveries. This allows you to meet customer expectations and enhance the overall customer experience.

Make sure your 3PL leverage best practices, technology, and expertise to optimize their logistics processes for speed and efficiency. Some 3PLs like ShipBob also offer a 2-Day Express Shipping program, which ensures that orders are delivered to your customers within two days. At ShipBob, we use a proprietary algorithm for this ship option to leverage a combination of ground, air, and regional carriers and maintain high on-time deliveries, with 99.96% of orders shipping on time within the service level agreement (SLA).

“ShipBob can handle our order volume because they’re experts at what they do. The last company I worked at had their own warehouse, and I witnessed firsthand how messy and complicated fulfillment can be, especially at scale when it’s not what your company specializes in. ShipBob’s fulfillment centers are nothing like that.

I’ve been to multiple ShipBob locations, and I’ve seen how much they’ve invested into automation and how organized everything is. It’s no wonder that orders get out within 24 hours of being received – ShipBob is really good at what they do.”

Tyler McCann, Co-Founder of Taste Salud

3. Inventory accuracy

Most 3PL providers take care of storing ecommerce inventory in addition to fulfilling orders. This means that ecommerce brands should track inventory accuracy, which measures inconsistencies between inventory records and actual physical inventory in the 3PL warehouse.

Your inventory accuracy rate plays a crucial role in your procurement and planning. If you maintain accurate inventory records, you can know exactly how much inventory you have in stock and time replenishment to avoid stocking out. Similarly, you can prevent overstocking since you know when you have sufficient stock for a certain item.

If your 3PL has low inventory accuracy, chances are their methods of inventory tracking and accounting are out-of-date or manual. This approach isn’t scalable in the long-term, and often results in costly errors that your ecommerce business pays the price for.

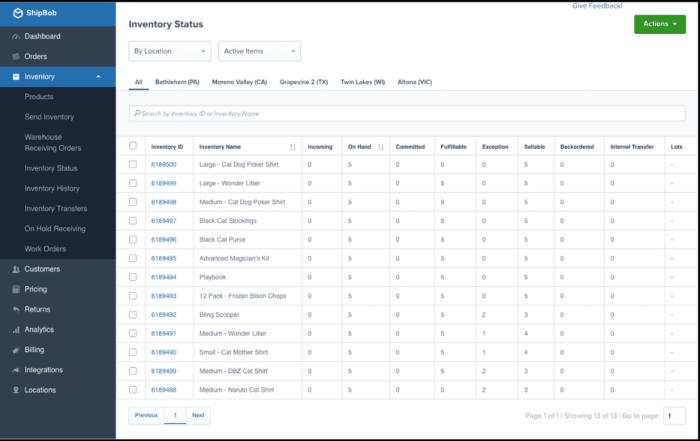

Instead, brands should find a fulfillment partner that leverages modern, automated inventory management software. ShipBob’s software, for example, features built-in inventory management capabilities and includes real-time inventory tracking capabilities. This tracks your inventory movement in real time, ensuring that your records are always balanced with your physical inventory.

4. Cost per unit shipped

Your cost per unit shipped measures how much you’re spending for every unit that gets shipped out from the 3PL. It accounts for both variable and fixed costs associated with fulfilling and delivering a single unit to the end customer, including shipping fees.

The more units you ship out within a specified time period, the lower your cost per unit shipped will be – so if your cost per unit shipped is low, your 3PL is probably performing efficiently.

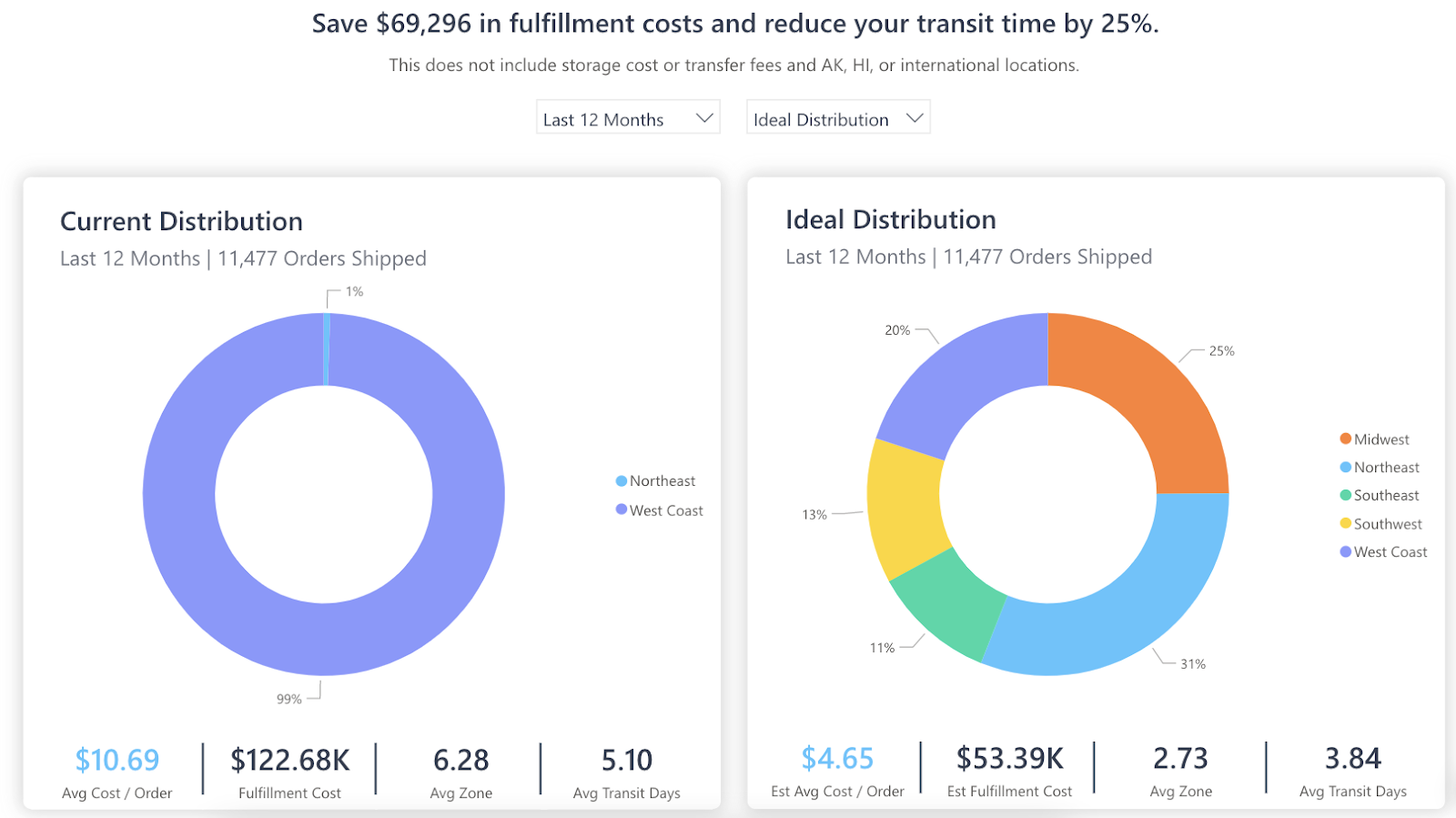

Beyond maintaining efficient operations, a 3PL can also lower your cost per unit shipped by lowering your shipping costs. One of the best ways to reduce shipping costs is through distributing your inventory across multiple strategically-located fulfillment centers, to put inventory closer to customers and minimize transit distance and times.

For instance, ShipBob offers brands a network of dozens of fulfillment centers all across the US – and the world – that brands can store inventory in and fulfill orders from. Not only does this cut shipping times for customers, but it also cuts shipping costs for merchants. Brands can even use ShipBob’s Ideal Inventory Distribution tool to compare their current split with the split ShipBob recommends based on your order history to save as much money as possible.

5. Transit times

Short transit times are critical for ecommerce brands, whether it’s lead times for manufactured goods or last-mile delivery for end customers. Your 3PL should be able to move goods from one supply chain stage to another quickly and cost-effectively and keep you in the loop the entire time with transparent tracking.

ShipBob’s proprietary WMS calculates optimal picking routes to reduce transit time in the fulfillment process. Our algorithm also helps to optimize shipping routes to reduce transit times during final mile delivery.

6. Returns processing efficiency

The returns management process is often overlooked – but with growing competition and customers’ increased demand for convenience, businesses need to effectively manage their returns by ensuring speedy reverse logistics, efficient processing, and fast refunds.

A 3PL that can integrate with leading returns management tools and offers automated returns processing can help you streamline this aspect of your ecommerce operations. They should also ideally offer various options to manage your returned inventory, such as restocking, discarding, or quarantining it. You’ll also want to measure how efficiently they process and sort returned inventory, as it’ll eventually affect the speed of your overall operations.

How to manage 3PL performance (step-by-step)

Effective 3PL performance management requires proactive planning and responsive adjustments. This helps you create a continuous improvement cycle to support ongoing management.

1. Establish clear performance expectations and SLAs

It’s important to start with a clear outline of the performance you expect from your 3PL, so lay out a comprehensive service level agreement (SLA) upfront where you document all your expectations in writing, and state how you’ll both be measuring the partner’s performance. This gives both parties clarity and common expectations, helping you avoid conflicts further down the line.

Make sure to get as specific as possible about the KPIs that you’ll be using to measure 3PL performance, so you can draw up contracts with terms that specify your expectations and hold the 3PL to those terms.

For example, your SLAs could specify that you and your 3PL agree on a minimum order accuracy rate of 99%, a minimum on-time fulfillment rate of 98%, and so on. Additionally, you can lay out the target numbers for other performance metrics like:

- Inventory accuracy

- Cost per unit shipped

- On-time delivery

- Return processing time

- Shipping accuracy

- Inventory turnover

- Average lead time

- Carrying costs

- Picking accuracy

- Receiving time

- Average order processing time

- Rate of returns

While it’s important to set ambitious performance targets, you should be equally realistic. Consider industry benchmarks and company-specific averages that make sense for your brand.

2. Implement robust performance monitoring systems

The ability to get real-time visibility into your fulfillment operations will help you stay on top of your 3PL performance.

Make the most of performance monitoring systems that integrate with various third-party tools and 3PL technology to enhance visibility across the supply chain. This should provide you with key insights into different aspects of your fulfillment performance and manage it accordingly.

You should be able to:

- Get accurate insights into how orders are picked, packed, and shipped, including metrics related to speed, accuracy, and cost.

- See real-time inventory levels and track inventory KPIs like turnover, carrying costs, and more.

- Integrate with third-party carrier software, so you can get real-time updates on order deliveries and maintain transparency for last-mile delivery performance.

- Pull and view automated reports and alerts are ideal to help you stay on top of key performance insights across your fulfillment operations and make timely improvements.

3. Develop a consistent communication cadence

Effective communication is vital for making any partnership work, as it gives you the chance to discuss challenges and work through them. That’s why you need a strategy for maintaining consistent communication with your 3PL partners to manage their performance.

Develop a schedule for regular performance reviews, whether it’s on a weekly, monthly, or quarterly basis. For example, you could do monthly reviews of performance KPIs and schedule quarterly meetings for thorough evaluations. This will create an opportunity to review how the 3PL has performed across some of the key performance indicators and address any areas for improvement.

Ideally, you should have a scorecard to help you easily evaluate 3PL performance during your scheduled review sessions. Have a system to grade whether their performance was good, satisfactory, or poor across each metric. Your scorecard should also include a comment section for any additional notes.

Here’s an example of a 3PL performance scorecard template to help you streamline your communications.

| KPI Measure | Monthly Evaluation | Comment | ||

| Month 1 | Month 2 | Month 3 | ||

| Fulfillment accuracy | Good | Needs Improvement | Good | Minimal errors in fulfillment |

| Fulfillment speed | Poor | Needs Improvement | Needs Improvement | Orders fulfilled slower than expected; improvements noticed after feedback |

| On-time fulfillment | Poor | Needs Improvement | Needs Improvement | A significant number of orders failed to fulfill on time; improvements noticed after feedback |

It’s good to note that peak seasons are when you’ll likely notice some issues with performance 3PLs need to fulfill higher order volumes. This is also when you’ll likely experience difficulty maintaining communications with 3PL staff balancing increased workload and client demand, so you need to work closely with the 3PL well ahead of time and work out how to maintain productive communication for the upcoming peak season.

4. Create action plans for performance gaps

No 3PL is perfect, since uncontrollable supply chain disruptions and unpredictable issues often affect performance. What matters is having a system in place to address any performance gaps with your 3PL partner.

A collaborative problem-solving framework is essential so you can take a systemic approach to address underperformance. This might involve highlighting the performance issues during your monthly reviews and giving them a chance to work on improvements. Establish clear and realistic timelines for when to see these improvements, such as by the next performance review or after a certain number of months.

If there are any recurring issues, performing a root cause analysis will help you figure out the source and address it appropriately. Work with the 3PL to identify what causes those issues and how to fix them.

5. Scale operations while maintaining performance standards

One of the most challenging aspects of managing 3PL performance is maintaining quality even as you scale your operations. Even a 3PL that once excelled in every metric might start to experience issues with speed and accuracy when handling increased fulfillment demand.

If you plan to scale into new markets or channels, make sure your current 3PL has the services and capacity to scale with you – or else you’ll need to switch.

You can also consider other fulfillment options, such as a hybrid approach where you outsource some fulfllment and still fulfill some of your orders in-house. For example, you might consider outsourcing to a 3PL with international fulfillment centers while handling your domestic fulfillment in-house.

You’ll also want to use data to inform your efforts to scale. Look into your sales and demand trends to understand seasonal peaks, so you can plan your capacity accordingly. Similarly, effective capacity planning is crucial before running promotional events that could lead to demand spikes.

You can also look into geographical demand patterns to see where most of your customers are located. This will help you identify whether to add more fulfillment locations to better serve your customers in those areas.

Red flags to look for in 3PL performance

🎯 Persistent order accuracy problems

If you repeatedly encounter issues with customers receiving incorrect items or incomplete orders, your 3PL isn’t doing its job. it’s an indicator of poor 3PL performance. It could be due to a number of reasons, such as:

- Human error during the picking and packing process

- Poorly integrated systems

- Data entry errors

- Poor inventory organization

If accuracy problems become persistent, it’s important to work with your 3PL to figure out the root cause and address it. If the 3PL fails to implement solutions even with reasonable timelines, it may be time to reevaluate your partnership.

⏰ Shipping delays and missed deadlines

Delays during peak seasons and supply chain disruptions aren’t ideal, but are sometimes inevitable – but if the 3PL continues to struggle with poor delivery performance even outside of these exceptions, it indicates a larger problem.

First, figure out if the missed deadlines are a result of delays with the carrier or the fulfillment center itself. For example, if the 3PL consistently meets shipping timelines but still experiences delivery delays, it may be a carrier-related issue. In this case, you might want to discuss using alternative carrier options.

On the other hand, if you’re noticing consistent patterns of delays with activities related to the fulfillment center, it’s probably an issue with the 3PL itself. Try to pinpoint where the delays occur and work out a solution accordingly.

☎️ Communication breakdowns and lack of transparency

Emails that go unanswered, responses that arrive a week too late, unclear information, having to send multiple follow-ups – these are all indicators of poor communication practices.

These communication breakdowns can make it extremely challenging to work with 3PL partners, and to run your own business effectively. When you don’t get a proactive notification about issues, it could prevent you from making timely decisions and solving problems on time. This could seriously impact other aspects of your operations and eventually affect the customer experience.

🎁 Inability to scale during peak periods

Every ecommerce business sees peak demand at some point, and it’s crucial to partner with a 3PL that can support these growing needs. Yet if your 3PL repeatedly experiences issues with delays and accuracies during peak periods, it may indicate an operational limitation.

Look into better, more accurate forecasting to plan your demand and capacity accordingly. Additionally, you might look into contingency plans to handle unexpected volume spikes, such as handling some of the fulfillment in-house. If the issues persist even with advanced planning, the 3PL may simply be incapable of scaling with your business.

Advanced strategies for optimizing 3PL performance

With the ecommerce landscape becoming increasingly competitive, simply having a “satisfactory” 3PL performance isn’t enough. Instead, businesses should strive for logistics excellence to gain a competitive advantage.

Leverage predictive analytics for proactive management

To effectively manage a 3PL (third-party logistics) partner, it’s important to spot and solve potential problems before they happen or get worse. That’s why using predictive analytics is essential — it helps you identify possible issues that could impact your logistics operations early on.

One of the key tools in this approach is accurate demand forecasting. These tools help you predict future sales and customer demand, giving you a clearer picture of how much inventory you’ll need and how much capacity to plan for. With this insight, you can work with your 3PL to prepare for busy periods in advance and put backup plans in place.

Using early warning systems is another important strategy. These systems can track things like political events, supply chain risks, and weather changes to alert you to potential delays or disruptions. This gives you more time to respond and reduce the impact on your operations.

Align 3PL performance with customer experience metrics

Aside from your product quality, your fulfillment operations are one of the biggest factors affecting customer satisfaction. Delays in delivery, inaccurate orders, damage in transit, and other fulfillment issues negatively impact the customer experience, so it’s important to closely monitor your customer experience metrics and align them with 3PL performance.

You’ll want to look into your NPS, CSAT, and retention metrics to understand how satisfied customers are with their experience. Conduct surveys to determine what resulted in positive and negative experiences. This will help you identify whether certain aspects of the fulfillment experience resulted in customer dissatisfaction, so you can work on improving them.

Optimize multi-node fulfillment networks

Unless you’re only serving customers in one specific region, distributed fulfillment is one of the best ways to optimize 3PL performance.

This involves using multi-node fulfillment networks and strategically distributing your inventory between different fulfillment centers. When a customer order comes it, it immediately gets routed to the ideal fulfillment center based on proximity and inventory availability. That means orders are fulfilled from the nearest fulfillment center, which allows for improved speed and lower shipping costs.

You can also use a cloud-based WMS that integrates data across all these fulfillment centers to identify demand patterns across different regions. This will allow you to balance inventory across multiple locations and prevent the risk of stockouts and understocking.

Develop a future-proof 3PL strategy

Effective 3PL performance management is also about adaptability. Your operations should be able to seamlessly adapt to the changing ecommerce and logistics landscape to help you keep up with the competition, so you can strengthen and future-proof your 3PL strategy in the long run.

Stay on top of emerging technologies and 3PL capabilities to understand how they can address your needs or solve key pain points. Being the first to implement these solutions will help you stay ahead of the curve and remain competitive in your industry.

Beyond this, see what competitors and retail giants are doing to understand how they’re shaping customer expectations. Look into market trends and consumer buying behavior to understand these changing expectations and adapt your 3PL strategy accordingly.

ShipBob’s industry-leading logistics services nurture ecommerce metrics

As an expert logistics partner, ShipBob offers ecommerce brands the transparency and visibility into performance and supply chain KPIs they need.

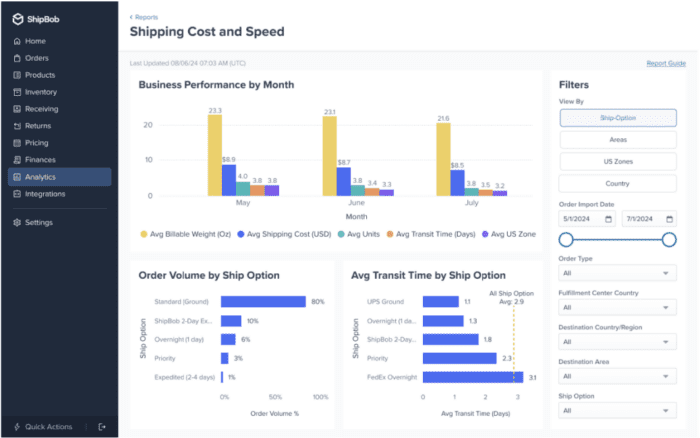

Advanced analytics and reporting tools

ShipBob’s free analytics reporting tool provides in-depth insights into your ecommerce performance. You can use this tool to track vital KPIs such as:

- Orders fulfilled on time, transit times, and other fulfillment metrics

- Shipping insights such as popular shipping methods, average cost per shipping method, and top selling states

- Cost breakdowns, including average storage cost per unit and average fulfillment cost per unit

- Inventory details like on-hand inventory levels,days left until stockout, and SKU-level performance.

Leveraging this data, you can identify areas for improvement and make more data-driven, strategic decisions for your ecommerce business.

“The ShipBob dashboard is great for real-time information with their built-in reporting. It’s one of the things that really separates ShipBob from the rest of the solutions on the market. I’ve oftentimes leveraged the data and analytics ShipBob provides when I’m preparing for sales meetings. I can see what our top selling states are, what our average fulfillment time and cost is, how much inventory we have on hand at each fulfillment center – a lot of different metrics that are very helpful. ShipBob has all of that information ready for us at any time.”

Tyler McCann, Co-Founder of Taste Salud

Real-time inventory management

ShipBob’s dashboard features real-time inventory management capabilities, allowing you to track inventory movement and balance your inventory records against your physical inventory. This also provides you with accurate inventory levels as well as automatic reorder notifications so you can time inventory replenishment perfectly and never run out of your best-sellers.

Simultaneously, this level of inventory visibility also ensures that you’re not ordering more inventory when you already have sufficient stock. This helps you avoid expensive storage costs and overstocking.

These real-time insights also enable you to strategically adjust your inventory distribution. If you see that one fulfillment center is running low on stock for a particular item, you can decide to move things around and maintain healthy stock levels across every location. With optimal stock levels at all your fulfillment locations, you can improve fulfillment speed and prevent customer disappointment.

“We have a Shopify store but do not use Shopify to track inventory. In terms of tracking inventory, we use ShipBob for everything — to be able to track each bottle of perfume, what we have left, and what we’ve shipped, while getting a lot more information on each order. The analytics are super helpful.”

Ines Guien, Vice President of Operations at Dossier

Scalable solutions

ShipBob goes beyond the traditional pick-and-pack 3PL model to deliver an expert supply chain and logistics platform for ecommerce brands. Our solutions won’t just help you pick orders, speed up fulfillment, or ship your packages; rather, ShipBob offers brands a partnership that streamlines your entire supply chain for efficiency and cost-savings while equipping you with the tools and capabilities you need to scale.

ShipBob’s suite of services includes:

- DTC and B2B fulfillment capabilities (including retail dropshipping and distribution)

- Omnichannel visibility across all locations and channels through a single dashboard

- Seamless integrations with dozens of major ecommerce platforms, tools, and popular retailers

- 60+ global fulfillment centers to expand into as you grow

- Customization capabilities, including gift notes, marketing inserts, and custom branded packaging

- A proprietary warehouse management system (WMS) to power and optimize operations in your own facilities

“Being able to expand our business without having to look for new partners was huge for us – and ShipBob makes it possible. ShipBob has a growth mindset, and is constantly adding new features and capabilities that are super beneficial to us, so we haven’t needed to look elsewhere for the tools to scale. There’s just so many ways we can grow with ShipBob, and we’re excited to take advantage of all of them.”

Jessica Cedarleaf, VP of Operations at Tonies

Customer testimonials

Hear from some real ShipBob customers about how they leverage ShipBob to optimize critical ecommerce KPIs.

Semaine Health

As Semaine Health started growing, their existing 3PL was unable to scale with them. They were making multiple mistakes in fulfilling DTC orders, and at the same time, their transit times were creating significant customer service headaches.

After partnering with ShipBob, Semaine Health joined the Inventory Placement Program to streamline inventory distribution. This helped them to allocate their inventory across four fulfillment centers, reducing their shipping times from 5.2 days to 3.6 days. Although the brand offers 2-day shipping for a premium, most of their orders get delivered within two days anyway after using the Inventory Placement Program. Semaine Health also managed to reduce average fulfillment cost per order by $2 compared to the previous 3PL.

“We literally would not have been able to expand this year without ShipBob. In the past six months, we’ve quadrupled the number of orders that we’re shipping out. You might expect that that jump in volume would cause issues – but fulfillment has only gotten faster and better. That’s not how it typically works! ShipBob’s solutions have been game-changing for our brand.”

Matt Crane, Co-Founder and Chief Science Officer at Semaine Health

Our Place

ShipBob’s technology and extensive fulfillment network has enabled brands like Our Place to significantly streamline their operations. The brand can now assign a single talented individual to manage all the workflows within an entire function. For example, one expert oversees their end-to-end operations across seven warehouses thanks to ShipBob’s technology and outsourced fulfillment services.

Our Place has also experienced significant cost savings and improvements in fulfillment efficiency. After expanding from two warehouses to four, they were able to save $1.5 million in freight expenses as they were now shipping locally to lower zones. This also cut their fulfillment and shipping times in half, enabling them to deliver orders in just 2.5 days when it previously used to take 5 to 6 days.

“ShipBob has transformed our operations into a key competitive edge. I doubt any of our competitors can match our ability to receive orders and deliver them within two and a half days at average. With ShipBob, misshipments are rare occurrences, enabling us to consistently deliver on our promises to customers, ensuring they receive exactly what they’ve ordered.”

Ali Shahid, COO of Our Place

To learn more about ShipBob’s SLAs and supply chain solutions for ecommerce brands, click the button below to get in touch.

Third-party logistics KPIs FAQs

Below are answers to the most commonly asked questions about 3PL KPIs.

How does ShipBob help improve order accuracy?

ShipBob helps improve order accuracy by running multiple checks and balances throughout the fulfillment process. Real-time inventory tracking software and advanced warehouse tools also ensure that the right items are shipped out in the right quantities and to the right addresses.

What analytics tools does ShipBob provide for tracking KPIs?

ShipBob provides a comprehensive analytics dashboard that lets you track vital KPIs related to your inventory, fulfillment, logistics, and shipping performance.

How can ShipBob’s 2-Day Express Shipping program benefit my business?

ShipBob’s 2-Day Express Shipping program helps you enhance customer satisfaction by ensuring that customers get their orders quickly. Moreover, a 2-day shipping badge can appeal to your customers and increase conversions.

How often should I review 3PL performance data?

You should typically review your 3PL performance data on a monthly or quarterly basis. Daily monitoring on a real-time basis is also essential, so you can quickly identify any issues or opportunities for improvement. This gives you the opportunity to address underperformance or quality issues before they turn into a bigger problem.

What should I do if my 3PL consistently misses performance targets?

If your 3PL consistently misses performance targets, you should work with them to identify the cause and come up with realistic solutions. Provide them with a realistic timeline to make improvements. If they still fail to deliver even after these efforts, you may want to reevaluate your partnership.