Verified & Reviewed

Published on September 22, 2025 Written By Rachel Hand

Published on September 22, 2025 Written By Rachel Hand

Subscribe for More

The best thing inventory can do is sell; the worst is to sit.

Every ecommerce business wants to sell their inventory quickly – after all, the faster inventory is sold, the faster you recoup your investment and earn your profits. Unsold inventory, on the other hand, takes up valuable storage space and racks up inventory holding costs that eat away at your bottom line.

To keep inventory from collecting dust on shelves, brands must monitor their inventory velocity – the rate and pace at which their inventory sells – and adjust their operations to optimize it.

In this article, we’ll cover what inventory velocity is, what factors impact it, how to measure it, and how an expert partner like ShipBob can help your business improve it.

What is inventory velocity?

Inventory velocity refers to the speed at which inventory moves through the supply chain or is sold.

It can measure either the time it takes to sell inventory after it’s acquired or the frequency at which it needs to be restocked.

In general, ecommerce brands prefer to have higher inventory velocity, since it is ideal for cash flow. However, if your inventory velocity is too high, it puts you at a higher risk of stockouts – so businesses will need to perform inventory cycle counts and monitor stock levels carefully to meet demand.

Inventory velocity vs. inventory turnover

The terms “inventory velocity” and “inventory turnover rate” are often used interchangeably and can refer to the same concept – but not always.

Inventory turnover ratio is a well-established metric specifically used for measuring the number of times inventory is sold and replaced during a given period. It is one way of measuring quantifying inventory velocity.

However, brands may also quantify inventory velocity on a more granular level by measuring the average time it takes to sell a particular SKU. This interpretation gives you a more dynamic view of inventory movement, and can help you assess which specific products are popular.

Inventory velocity formula: How to calculate

To calculate your inventory velocity, you’ll first need to calculate two metrics for your business for a particular period of time: Cost of Goods Sold (COGS) and Average Inventory Value.

The formula to calculate COGS is:

COGS = Starting Inventory + Purchases – Ending Inventory

The formula to calculate Average Inventory Value is:

Average Inventory Value = (Ending Inventory + Starting Inventory) / 2

Once you have these numbers, you can find out your inventory velocity using the formula below:

Inventory Velocity = Cost of Goods Sold / Average Inventory Value

As an example, say a clothing retailer starts the year with $25,000 worth of inventory. They make inventory purchases worth $40,000 throughout the year, and end the year with $15,000 worth of inventory. In this case, they would calculate inventory velocity for that year like so:

COGS = 25,000 + 40,000 – 15,000 = $50,000

Average Inventory Value = (15,000 + 25,000) / 2 = $20,000

Inventory Velocity = 50,000 / 20,000 = 2.5

This means that the retailer sold and replaced their entire inventory 2.5 times in one year.

Ideally, you want to keep inventory velocity between 2 and 4. If it’s lower than 2, it means you’re dealing with unsold inventory and risking dead stock. Anything higher than 4 means you could be at a high risk of stockouts.

Key metrics influencing inventory velocity

There are several other factors that affect a company’s inventory velocity. Whether the influence is direct or indirect, you will need to improve these metrics in order to improve your inventory velocity.

Demand forecasting accuracy

Accurate demand forecasting plays a vital role in effective inventory management.

When your forecasting efforts are adapted to match changing consumer demand, you can avoid the risk of stockouts and overstocking. This means you’re preventing excess inventory from building up while simultaneously ensuring that in-demand inventory keeps getting replenished to meet customer demand.

In other words, the accuracy of your forecasts will help you maintain optimal stock levels at all times while keeping demand variability in mind. It also ensures that your inventory velocity remains at an ideal rate.

Lead time for replenishment

The lead time for replenishing your inventory is another factor that will play a role in stock velocity. This refers to the time taken between a brand putting in a purchase order (PO) for replenishment and receiving the inventory from the supplier. Factors such as transit time will play a role in your lead time.

Longer lead times will subsequently lead to lower inventory velocity since it’s taking longer to replace stock. Additionally, long lead times will result in having capital tied up in inventory for longer periods of time. This will impact cash flow since you can’t sell the inventory if you haven’t received it yet.

Order fulfillment efficiency

Your inventory velocity is also determined by how quickly you process orders and get them out the door. This finalizes the sale, helping you generate cash flow to reinvest in your business. It also makes room for replenishment stock, allowing you to replace your inventory.

A good on-time and in-full (OTIF) rate ensures the seamless movement of goods through the system, which reflects in a healthy inventory velocity.

Return management effectiveness

It’s not just your replenishment orders that contribute to your overall inventory levels; you also need to account for other types of incoming inventory, such as returns. Some returned goods get added back to your inventory, while others may need to be discarded appropriately.

It’s important to effectively sort and manage these returns to reflect in your systems accurately. Once they’re available for sale again, they can move to the next stage of fulfillment instead of being stuck in storage – so an effective return management process will help you maintain healthy inventory velocity.

How inventory velocity can spark ecommerce success

Selling inventory faster isn’t just a confidence boost for your business; rather, optimizing your inventory velocity can positively multiple aspects of your ecommerce operations.

Greater customer satisfaction through faster delivery

High inventory velocity is often a sign of improved operational efficiency. It means that you’re maintaining optimal stock levels and getting orders out the door quickly. This facilitates faster deliveries, resulting in satisfied customers.

Moreover, if you’re replenishing inventory quickly, it minimizes the risk of stockouts and backorders so you can effectively meet consumer demand and ensure that your customers get what they want when they want it. They won’t have to wait for long periods of time to get the order, which boosts satisfaction.

Stronger cash flow and reduced holding costs

A high inventory velocity means less of your capital is tied up in unsold goods at any given moment. Rather, it’s quickly converted into cash that you can then reinvest in your business to reorder more goods and grow your operations.

Additionally, it prevents excess stock from building up and eating away at your profit margins through expensive holding costs. Since inventory moves quickly through the system, it allows you to make room for new stock, which will then translate to more sales and increased revenue for your business.

Push inventory velocity boundaries with ShipBob

With comprehensive fulfillment services and powerful inventory software, ShipBob empowers you to take your inventory velocity to the next level.

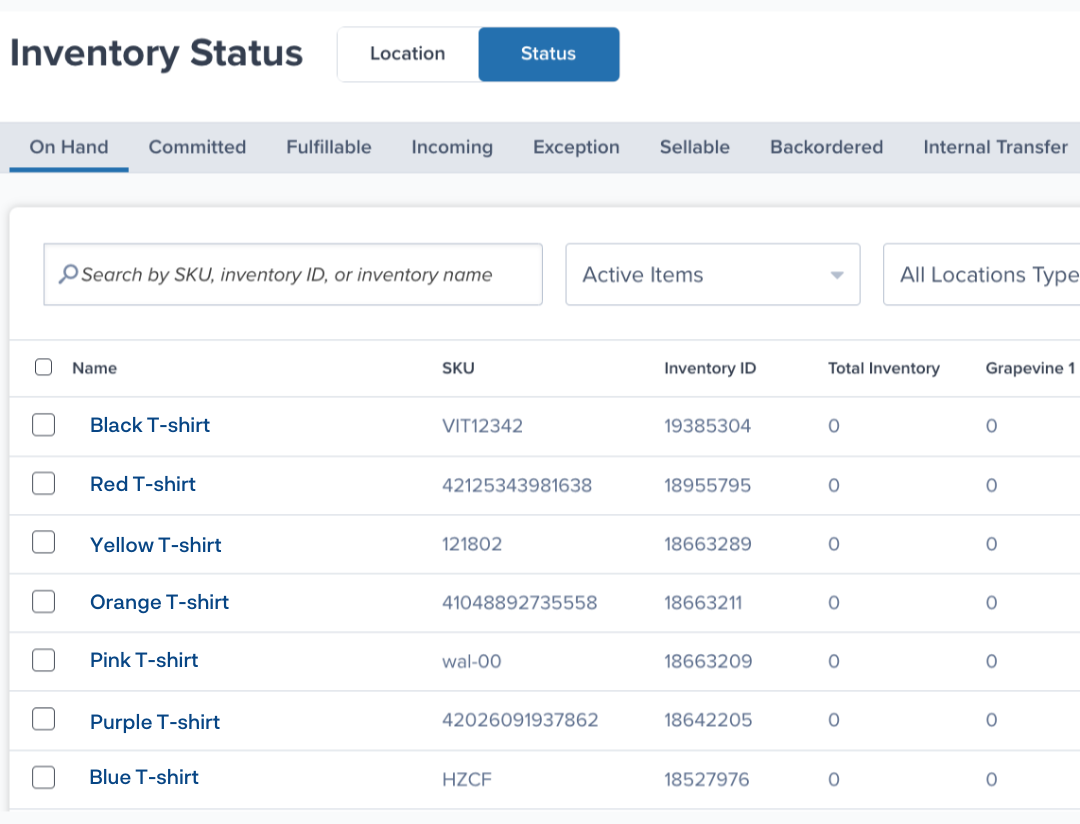

Real-time tracking for optimal inventory control

ShipBob’s platform features built-in inventory management software, complete with robust tools to help you track, manage, and analyze your inventory. This enhances your inventory control, as you get deep visibility and data-driven insights to make informed decisions that will facilitate a seamless flow of inventory.

It also provides real-time inventory tracking so you can monitor your stock levels at all times and get a realistic understanding of your inventory needs. You can combine this data with insights from the inventory analytics dashboard to get a comprehensive outlook of how much inventory you should reorder and when.

As a result, you can make timely replenishments to avoid running out of stock. This simultaneously allows you to avoid reordering more inventory when you still have sufficient stock.

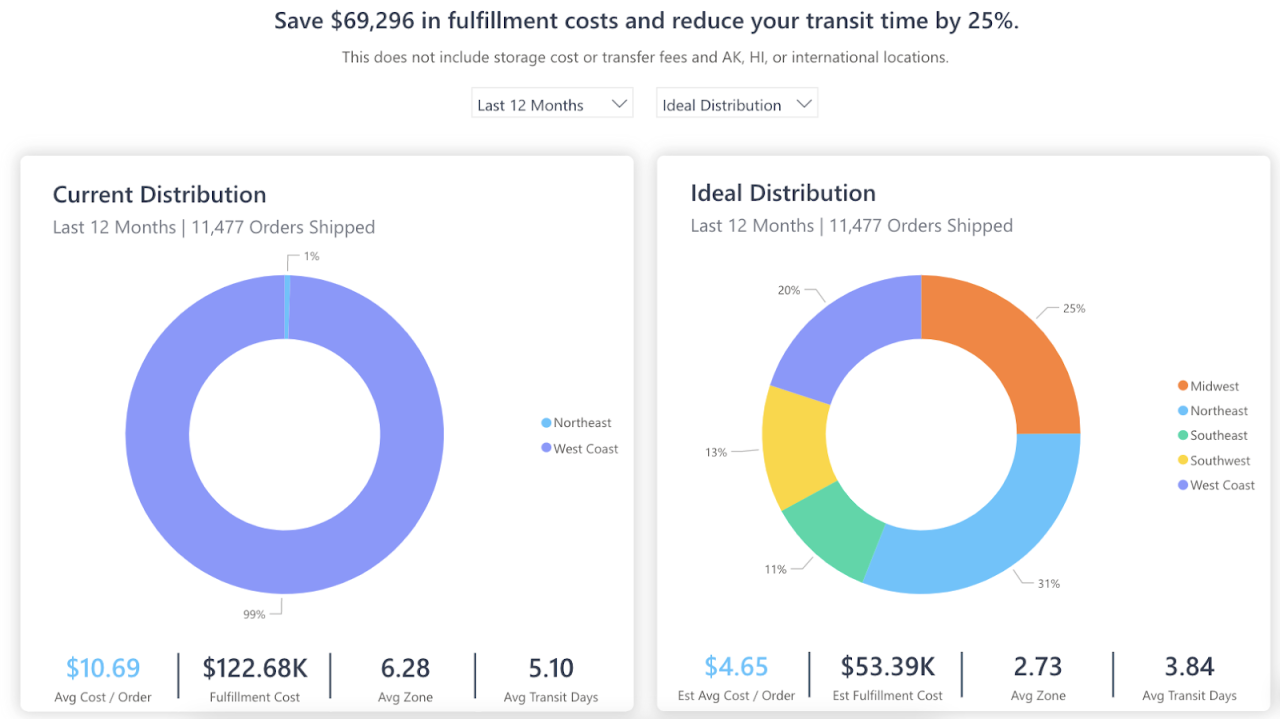

Strategic inventory distribution with ShipBob’s Inventory Placement Program (IPP)

U.S.-based merchants can also make use of the Inventory Placement Program to optimize their fulfillment operations and divert stock to regions where it’s most in demand. With IPP, ShipBob handles all the complex aspects of coordinating, managing, and distributing their inventory across various fulfillment centers.

ShipBob’s proprietary algorithm leverages your brand’s own order data to calculate the optimal locations to place your products:

When you distribute your inventory across more than one fulfillment center, you can reduce shipping zones and store inventory closer to your customers. This not only speeds up the delivery process but also helps to cut down on shipping costs.

Moreover, strategic quantity and demand recommendations can help you reallocate inventory from one fulfillment center to another based on usage. That means if one fulfillment center is running low on stock, you can easily send more inventory from another location that has sufficient stock. This is highly effective in avoiding excess stock build-up at one location and eventually boosts your inventory velocity.

“We’re fulfilling orders from 4 ShipBob fulfillment centers on the West Coast, Southwest, Midwest, and Northeast. By storing inventory and fulfilling orders from 4 different regions, we’ve been able to engineer it so that most of our shipments are within Zones 1 and 2. Eliminating high shipping zone ranges by distributing inventory is a no-brainer, and really helps us minimize our shipping costs, especially on high-velocity items.”

Neil Blewitt, SVP of Operations at Bloom Nutrition

Leverage a vast fulfillment network for faster delivery

ShipBob offers merchants an expansive fulfillment network to support strategic inventory distribution. With dozens of fulfillment centers in the US, UK, Europe, Canada, and Australia, you can store your inventory closer to your customers to facilitate faster deliveries.

You can even take advantage of ShipBob’s affordable 2-day fulfillment service for even faster delivery. This ensures that your customers get their orders within two business days across the continental US, so you can remain competitive in an industry where ecommerce giants such as Amazon have redefined customers’ delivery expectations.

Improve forecast accuracy with automated demand planning

ShipBob’s automated replenishment and demand forecasting tools help you manage stock levels proactively. Since the inventory management system ensures inventory accuracy, these tools also give you accurate insights into your inventory needs. You can improve your demand planning efforts with accurate demand predictions based on historical sales data, consumer demand trends, and inventory performance.

Meanwhile, automated reorder point notifications ensure that you get timely updates when it’s time to reorder stock. This helps you avoid expensive stockout costs and maintain optimal stock levels at all times.

Make informed decisions with comprehensive data analytics

ShipBob’s robust inventory analytics software gives you comprehensive insights into your inventory performance. You can use the analytics dashboard to track vital inventory KPIs such as SKU performance, inventory turnover rates, and historical demand patterns, and use those insights to make better, data-driven decisions.

ShipBob even delivers an entire Inventory Velocity Report, where you can find:

- Total units sold per SKU

- Average daily velocity per SKU

- Estimated days on hand

- Top 5 best-selling and worst-selling SKUs

“One of my favorite parts of ShipBob’s solution is the analytics I get through the ShipBob dashboard. I use the reporting constantly, especially to track my stock. It’s even helping me get better at inventory forecasting. Before, I was just fumbling through the demand planning process and just ordering inventory based on what sold out. But now I have insight into metrics like SKU velocity and inventory days on hand, and I’m using that to decide what to reorder and how much of it I need. That helps a lot, especially now that the brand is scaling and I’m ordering my products in bigger batches.”

Luke Rolls, Founder of The Protein Pancake

To see how ShipBob can help speed up your brand’s inventory velocity, click the button below to get in touch.

Inventory velocity FAQs

Below are answers to the most commonly asked questions about inventory velocity.

How can a company improve its inventory velocity?

A company can improve its inventory velocity by tracking inventory levels in real-time and stocking up in inventory at the right time. Strategic inventory distribution and pricing adjustments can also improve velocity.

How does inventory velocity affect supply chain efficiency?

Healthy inventory velocity is crucial to improve cash flow and ensure that other supply chain operations are functioning as intended. With sufficient capital to acquire more inventory, businesses can ensure that their supply chain velocity and processes move seamlessly with minimal disruptions.

What is a good inventory velocity rate?

Ideally, your inventory velocity rate shouldn’t be lower than 2 or higher than 4. A low inventory velocity means you’re not selling inventory fast enough, leading to stock build-up and risks of dead stock. Meanwhile, higher inventory velocity could lead to issues such as stockouts and backorders.