Retail returns eat into contribution margin long before inventory is back on a shelf. Labor at the dock, rescans, misrouted parcels, late refunds, and accounting clean-up all compound the cost of a single RMA. A barcode-first returns management workflow changes that math. When labels are standardized, scans are reliable, and data flows cleanly to the ledger, intake speeds up, refunds are accurate, and write-offs shrink. The goal is simple: fewer touches and fewer surprises.

The Margin Problem behind Returns—and why Scan Reliability Matters

Returns remain a material cost center for US retailers. Industry analyses show double-digit return rates and billions in reverse-logistics exposure each year; recent research from the National Retail Federation highlights both the scale and the operational friction that returns create for merchants and their finance teams.

For ecommerce brands, handhelds and scanners are the “first witness” at intake. If barcodes don’t decode consistently, associates reprint labels, hand-type order numbers, or set items aside for exception handling. Each rescue step adds minutes, invites error, and delays revenue recognition on resellable goods. The fix is not only better hardware. It’s a clear, enforced labeling standard paired with software and SOPs that keep every scan fast and accurate.

A Barcode-First Returns Management Workflow

Start upstream with the RMA. The best downstream scans begin with a customer-facing flow that issues a scannable RMA ID, embeds order and item identifiers, and prints a label with the right symbology and quiet zones. If you sell on multiple channels, harmonize how RMAs are created so the dock team sees a single, predictable label format regardless of origin.

At the dock, triage should be the same every time. Each parcel is scanned on arrival to log chain of custody; the RMA ID links the shipment to order metadata and the customer’s refund method. As the box opens, item-level barcodes confirm what’s actually inside. That second scan is where most intake stalls when codes are creased, low-contrast, or cropped. A small investment in print quality standards and verification—before labels ever reach customers—prevents the pile-up.

In the inspection lane, a single decision point records disposition codes: restock, refurbish, scrap, or return-to-vendor. Map each disposition to accounting rules so inventory movements and cost reversals post automatically. If the item is restockable, a final location scan books it into available inventory and closes the loop for sales channels.

Labeling Standards that Reduce Rescans and Rework

Standards are the difference between “works most of the time” and “works under pressure.” Quiet zones (the blank margin around a code), symbol contrast, X-dimension, and print resolution determine whether a symbol decodes on the first try. GS1’s verification guidance explains how to spec and grade print quality so barcodes decode under real-world lighting and handling.

Beyond print quality, choose symbologies and data elements that match your catalog and workflows. A typical setup uses a shipment-level code on the outer label and item-level codes inside the box. If you’re adding 2D symbols for compact data—say GS1 DataMatrix for serials or lot numbers—document where each data point lives so associates know exactly what to scan and when. Formal verification against ISO/IEC methods is worth the effort when volume grows; it gives operations a pass/fail gate before labels go into the wild and keeps the dock out of firefighting mode.

Software completes the picture. Barcode SDKs and verification tooling, embedded in your label generation or returns portal, help ensure consistent scans by enforcing symbology, size, and error-correction settings at the moment a label is created—not after it fails on the warehouse floor.

Returns Management for Finance: Where the Entries Land

Operations own the scanner, but finance owns the impact. The intake lane should feed clean data into three places without manual rekeying.

First, refunds and credits need to reconcile against receivables and payment processor reports. A reliable RMA ID and order ID pair make matching straightforward and prevent duplicate refunds. If you want a primer on the receivables side, the overview on gross vs net accounts receivable is a good foundation for deciding what to net against processor fees and what to carry as open credits.

Second, returns require cost reversals. When restockable goods come back, you reverse COGS at the original cost flow (FIFO or weighted average). When items are scrapped, you may book a write-off to shrink or damage rather than inventory. The mechanics are covered step-by-step in COGS journal entries and related examples, and those same patterns apply to returns.

Third, management reporting depends on clean tags. Map each disposition to a reason code so finance can segment “didn’t fit,” “arrived damaged,” “defective,” or “changed mind.” Reason codes tie directly to your dashboard. If you’re formalizing KPIs, ecommerce financial metrics outlines return rate, refund cycle time, and write-off percentage as levers you can track month to month.

Building The RMA and Intake Experience the Right Way

Customer-facing returns set the tone for margin protection. If you use a portal, pre-populate RMAs with item lines and quantities from the order history, and generate a single scannable ID that stays with the parcel from kitchen table to receiving bay. When customers print at home, your template should lock in module width, minimum quiet zones, and color use; if it must print in grayscale, avoid light fonts or graphics near the code.

On the label itself, place the RMA code in a protected area with no perforations or folds, then include the order ID or shipment code as a secondary symbol or human-readable line. The secondary ID is there for exceptions, not as the primary scan target. Inside the box, item-level barcodes should remain intact even if product packaging is opened; where feasible, add a small internal label for apparel or soft goods that lose hangtags during try-on.

At receiving, the first scan should open a single intake screen. That screen confirms customer, refund method, and items expected. As associates inspect each item, they scan the product code to record condition and choose a disposition from a short, enforced list. The system applies business rules: automatic restock and COGS reversal for A-grade items, quarantine for refurbish, immediate write-off for unsellable goods, or RTV for vendor agreements. Refunds post only after final disposition, preventing over-refunds on incomplete boxes.

Quality Control that Keeps the Line Moving

Returns spikes expose weak labeling. Build a light verification routine into your week so issues never reach peak season. Print a sample batch of labels from each channel and verify against your chosen grading method; even a simple A–F grade with ten-scan average for 1D codes tells you whether print contrast or quiet-zone violations will trip you up under warehouse lighting. Document the acceptable grade and hold anything that scores below your threshold until it’s fixed.

When a scan fails at intake, avoid improvisation. Associates should reprint from the returns system, not invent a new ID or hand-type a shipment number. Failed labels go to a small “exceptions” box for root-cause review. Most failures trace back to common issues—printer settings, label stock, or templates modified by a marketplace update—which can be addressed with a single change rather than repeated rescans.

Analytics that Prove Margin Protection

A barcode-first process is easy to measure. Watch first-pass scan rate (the percentage of parcels and items that decode on the first attempt), average seconds per item from first scan to disposition, refund cycle time from dock to processor, and the share of returns that reenter sellable inventory. Those four numbers show whether your SOPs actually protect margin or simply move the bottleneck.

Overlay those measures with reason codes and channel to see where defects originate. If “arrived damaged” clusters to a specific 3PL lane, you have a packaging or carrier problem. If “wrong item shipped” spikes on one SKU family, audit pick lists and bin labels in that zone. Over time, finance can attribute improvements in return-related write-offs to specific operational fixes rather than global targets.

Where Industry Guidance Fits

You don’t need to invent your own barcode rules. GS1 provides accessible guidance on verification, quiet zones, and symbol contrast that you can adopt as your internal spec without starting from scratch. For the broader business case, returns research from NRF summarizes cost pressures and fraud trends that justify a more disciplined, barcode-driven approach during budget planning.

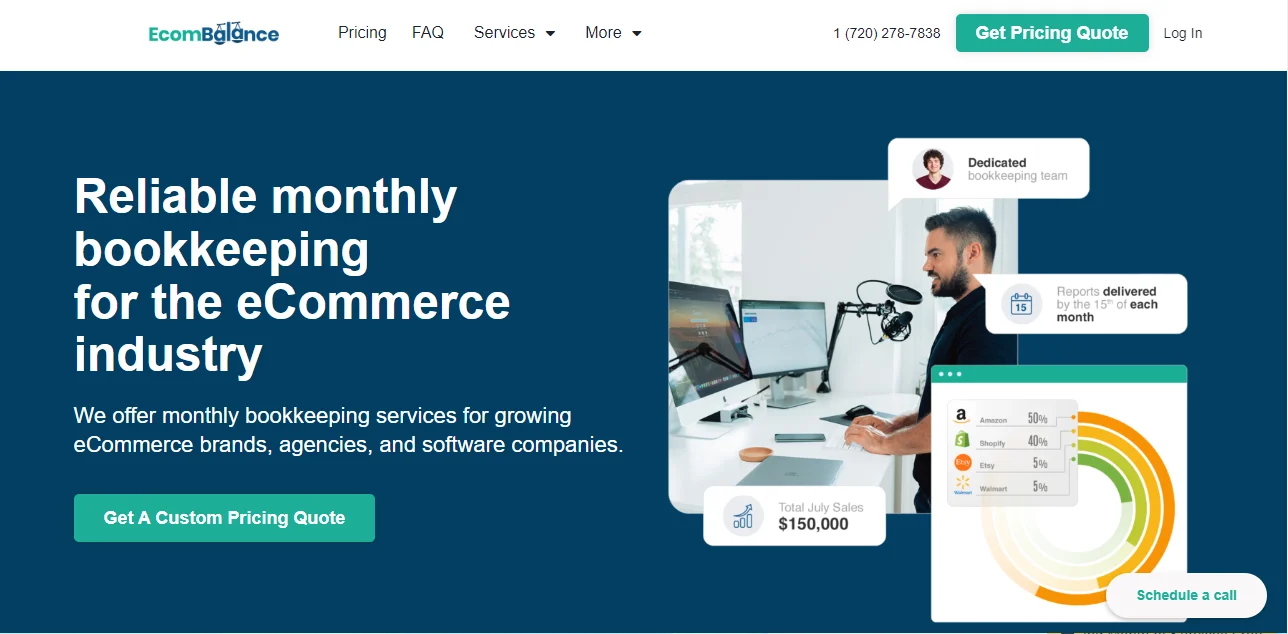

What Is EcomBalance?

EcomBalance is a monthly bookkeeping service specialized for eCommerce companies selling on Amazon, Shopify, eBay, Etsy, WooCommerce, & other eCommerce channels.

We take monthly bookkeeping off your plate and deliver you your financial statements by the 15th or 20th of each month.

You’ll have your Profit and Loss Statement, Balance Sheet, and Cash Flow Statement ready for analysis each month so you and your business partners can make better business decisions.

Interested in learning more? Schedule a call with our CEO, Nathan Hirsch.

And here’s some free resources:

- Monthly Finance Meeting Agenda

- 9 Steps to Master Your Ecommerce Bookkeeping Checklist

- The Ultimate Guide on Finding an Ecommerce Virtual Bookkeeping Service

- What Is a Profit and Loss Statement?

- How to Read & Interpret a Cash Flow Statement

- How to Read a Balance Sheet & Truly Understand It

Conclusion: Returns Management that Actually Protects Margins

Barcode workflows protect margins when they start at the RMA and end in the ledger. A standard label template, verified print quality, and a single intake screen reduce rescans and rework. Clear disposition codes keep accounting tidy, reversing COGS correctly and matching refunds without manual effort. With those pieces in place—and labeling software to help ensure consistent scans—returns management shifts from a costly fire drill to a predictable, measurable process that supports profitable growth.