Verified & Reviewed

Published on September 18, 2025 Written By Meredith Flora

Published on September 18, 2025 Written By Meredith Flora

Subscribe for More

Ecommerce success today requires a supply chain ecosystem: a network of partners, technologies, and processes working in harmony. This data-driven approach replaces linear, siloed operations with a collaborative system where real-time information flows seamlessly between suppliers, fulfillment centers, and carriers.

The payoff for building this ecosystem? Faster deliveries, lower costs, improved sustainability, and superior customer experiences. In this guide, we’ll break down the essential components of a modern supply chain ecosystem and provide actionable strategies to transform your operations into a resilient, adaptive network that drives competitive advantage in today’s complex marketplace.

What is a supply chain ecosystem?

A supply chain ecosystem is a dynamic, interconnected network of partners, technologies, and processes that collaboratively work to move products from suppliers to end customers. This evolving system goes beyond the traditional, linear supply chain model by fostering real-time data sharing, adaptability, and synergistic relationships among all participants.

In a supply chain ecosystem, components like suppliers, manufacturers, logistics providers, and fulfillment centers are connected via AI, blockchain, and IoT. This connectivity enables seamless information flow, helping the ecosystem respond swiftly to market changes, customer demands, and disruptions.

By embracing this approach, ecommerce brands can unlock operational agility, resilience, and efficiency. Real-time data visibility across the network empowers businesses to make informed, proactive decisions, while strategic collaboration among partners drives continuous improvement and innovation. Moreover, the ecosystem model prioritizes sustainability and customer-centricity, ensuring that these critical aspects are woven into the fabric of the supply chain.

Traditional linear chains vs. modern ecosystems

Supply chain ecosystems differ from traditional, linear supply chains. Conventional supply chains often operate in silos, with each stage of the process functioning independently and sequentially. This lack of integration leads to limited visibility, delayed decision-making, and a reactive approach to problem-solving.

In contrast, modern supply chain ecosystems are characterized by interconnectivity, collaboration, and proactivity. By leveraging digital tools, ecosystems create a transparent environment where all participants have access to real-time data insights. This enables swift, informed decision-making and allows the network to adapt quickly when needed.

While traditional supply chains often treat sustainability and customer experience as afterthoughts, modern ecosystems embed these values into their core operations. By optimizing transportation routes, reducing waste, and leveraging data to anticipate customer needs, ecosystems can simultaneously minimize environmental impact and deliver exceptional service.

Key components of a modern supply chain ecosystem

A robust supply chain ecosystem consists of interconnected elements working together to create more value than any single component could deliver alone. Through technology and data sharing, modern ecosystems break down traditional boundaries between these essential components.

Suppliers and manufacturers

Today’s supplier relationships have evolved from simple transactions to strategic partnerships built on real-time data sharing. This collaboration improves production planning and inventory management while reducing stockouts and waste.

Ethical sourcing has become essential, with brands ensuring suppliers follow responsible labor and environmental practices. Technologies like blockchain verify product authenticity, building trust with consumers.

Lead time accuracy is critical as disruptions at the supplier level can cascade throughout the network. Predictive analytics and real-time communication help brands and suppliers anticipate and resolve potential issues before they impact the entire ecosystem.

Transportation and logistics partners

From freight forwarders to last-mile delivery providers, transportation partners connect all ecosystem components. Real-time tracking with IoT sensors and GPS technology enables proactive decision-making, while predictive analytics optimize routes and capacity planning.

For global operations, experienced logistics partners help navigate cross-border complexities like customs compliance and international shipping regulations. Multi-carrier strategies create resilience against disruptions while optimizing costs and service levels based on shipment characteristics.

Fulfillment infrastructure

Warehouses and distribution centers significantly impact delivery times, costs, and customer satisfaction. Distributed fulfillment, or positioning inventory across multiple locations near customers, enables faster delivery while reducing transportation costs and emissions.

Third-party logistics providers (3PLs) offer scalable solutions that integrate with other ecosystem components. By outsourcing fulfillment, brands access advanced technologies like robotics without major capital investment, while gaining expertise in inventory management and order processing.

Technology and data integration

Technology functions as the ecosystem’s nervous system, enabling real-time visibility and optimization. AI and machine learning analyze data to forecast demand and optimize inventory, while automating complex decisions like routing.

Seamless integration between systems through APIs creates a unified view of the entire ecosystem. Emerging technologies like blockchain secure and verify transactions, while IoT sensors monitor product conditions in transit, enabling proactive quality control.

Sustainability frameworks

Sustainability has become essential in modern supply chains, driven by regulations and consumer demand. Strategic network design and transportation optimization reduce carbon emissions by minimizing shipping distances.

Sustainable packaging using recycled or biodegradable materials reduces environmental impact while appealing to eco-conscious consumers. Many brands implement circular economy models where packaging is designed for reuse or recycling.

Effective sustainability requires measuring environmental performance through metrics like carbon emissions and waste generation. Technology automates data collection for accurate reporting, while sustainability initiatives drive innovation and efficiency, helping brands differentiate themselves in competitive markets.

Transforming from linear to distributed fulfillment models

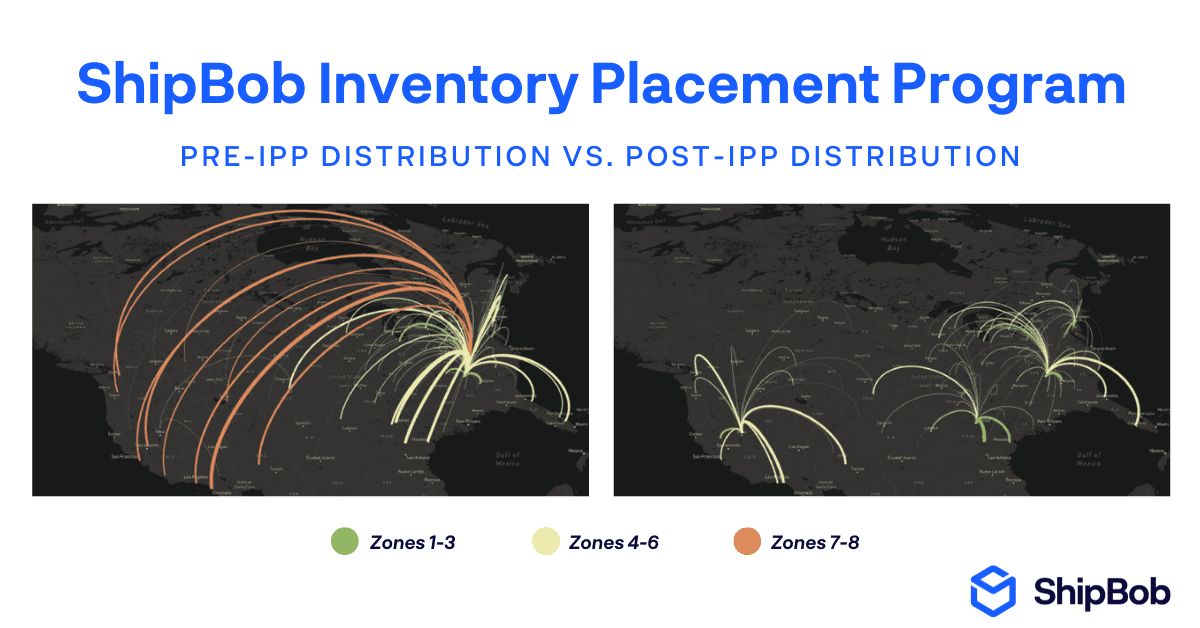

Traditional ecommerce fulfillment relied on a single warehouse shipping all orders, a model that can’t meet today’s customer expectations for fast, affordable delivery. But distributed fulfillment solves this by positioning inventory across multiple locations closer to customers. This approach dramatically cuts shipping times and costs, allowing brands to offer the speedy delivery modern shoppers demand.

The data supports this shift: 66% of consumers expect free shipping, and 29% abandon purchases due to slow delivery times. Strategic inventory distribution helps brands meet these expectations without breaking their budget.

Implementing a distributed model requires strategic planning. Brands must analyze order patterns, customer locations, and product characteristics to determine optimal fulfillment center placement. Smart inventory allocation ensures products are available where they’re most needed.

Having systems that offer real-time inventory visibility across all locations, and tools to manage stock movement between facilities, is crucial. Advanced analytics help predict demand patterns and optimize inventory levels.

ShipBob has over 60 fulfillment centers throughout North America, Europe, and Australia, and offers our Inventory Placement Program, an automated inventory distribution and replenishment solution for brands fulfilling orders in the US. Our platform provides brands with complete visibility and control over their inventory, eliminating the need for infrastructure investment, and our data-driven approach optimizes stock placement and replenishment.

Balancing B2B and DTC operations in one ecosystem

Many brands now face the challenge of managing both wholesale (B2B) and direct-to-consumer (DTC) channels simultaneously. These channels have fundamentally different requirements. B2B involves bulk, palletized shipments to businesses and retailers, while DTC means smaller, more frequent orders shipped to customers.

Success requires an integrated approach using shared inventory and infrastructure for both channels. This demands a flexible warehouse management system that handles pick-and-pack and bulk processing, plus unified inventory visibility across all sales channels.

Smart inventory allocation prevents stockouts by balancing wholesale commitments with DTC demand. Real-time visibility is crucial for making informed decisions about where to direct available stock.

Integrated technology connects your ecommerce platform, ERP, and warehouse systems to create a single source of truth. APIs automatically route orders to the appropriate fulfillment workflow based on channel-specific rules.

ShipBob’s platform seamlessly handles both B2B and DTC fulfillment within the same infrastructure. Our WMS accommodates the unique requirements of each channel while maintaining unified inventory visibility, eliminating the need for separate systems or processes.

How to build a resilient, future-proof supply chain ecosystem

Building a resilient and future-proof supply chain ecosystem requires a comprehensive approach that prioritizes visibility, flexibility, and proactive risk management. By following a structured framework, brands can develop or optimize their ecosystem to ensure overall health and performance.

Conduct a comprehensive supply chain audit

The first step in building a robust supply chain ecosystem is to evaluate your current performance. Conduct a thorough audit of your existing processes, partners, and technologies to identify strengths, weaknesses, and opportunities for improvement.

Key metrics to assess include:

- On-time in-full (OTIF) delivery rates

- Inventory turnover and carrying costs

- Order cycle times and lead times

- Transportation costs and efficiency

- Customer satisfaction and Net Promoter Score (NPS)

By analyzing these KPIs, you can pinpoint bottlenecks, single points of failure, and areas where technology can drive optimization. Use this audit as a foundation for developing a strategic roadmap for ecosystem enhancement.

Design your optimal network structure

With insights from your supply chain audit, you can begin to design your ideal network structure. This involves determining the optimal number and location of fulfillment nodes based on factors like customer geography, order volume, and product characteristics.

Data-driven tools like network optimization algorithms can help you evaluate different scenarios and identify the most efficient configuration. Consider factors like transportation costs, inventory carrying costs, and service level targets when designing your network.

For brands expanding internationally, it’s crucial to incorporate cross-border logistics considerations into your network design. Identify strategic locations for global fulfillment centers, and select partners with expertise in navigating customs regulations and tariffs.

Implement integrated technology solutions

Technology is the glue that holds a supply chain ecosystem together. To create a seamless, data-driven network, you need to implement integrated solutions that connect all components of your ecosystem.

Your technology stack should include:

- Ecommerce platforms for order management and customer engagement

- Warehouse management systems (WMS) for inventory control and fulfillment operations

- Transportation management systems (TMS) for carrier selection and shipment tracking

- Enterprise resource planning (ERP) software for financial and operational data

- Business intelligence and analytics tools for data-driven decision-making

Ensuring seamless integration between these systems is critical for creating a unified view of your ecosystem. Look for solutions with open APIs and pre-built connectors to minimize custom development work.

ShipBob’s fulfillment platform integrates directly with major ecommerce platforms like Shopify, Magento, and BigCommerce, enabling brands to create a cohesive ecosystem with minimal technical heavy lifting.

Develop proactive risk management strategies

Resilience in the face of disruption is a hallmark of a healthy supply chain ecosystem. To build this resilience, brands must develop proactive strategies for identifying, prioritizing, and mitigating risks.

Common supply chain risks include:

- Supplier failures or capacity constraints

- Transportation disruptions due to weather, labor disputes, or capacity shortages

- Demand spikes or dips due to market changes or external events

- Quality issues or product recalls

- Cybersecurity breaches or data loss

For each identified risk, develop contingency plans and alternative sourcing strategies. Establish clear communication protocols for alerting partners and customers in the event of a disruption.

Predictive analytics can help you anticipate potential issues before they impact your operations. By analyzing data on supplier performance, transportation metrics, and demand patterns, you can proactively adjust your strategies to minimize risk.

Embed sustainability throughout the ecosystem

Sustainability is no longer a nice-to-have; it’s a business imperative. To build a future-proof ecosystem, brands must embed environmental and social responsibility into every aspect of their operations.

Some key strategies for driving sustainability include:

- Selecting suppliers and partners with strong environmental and ethical track records

- Optimizing transportation routes and modes to reduce carbon emissions

- Implementing circular economy principles like recycling, reuse, and waste reduction

- Leveraging renewable energy sources for warehousing and logistics operations

- Setting clear sustainability targets and transparently reporting on progress

Distributed fulfillment models, like those enabled by ShipBob’s network, can reduce environmental impact by shortening delivery distances and minimizing transportation emissions. By storing inventory closer to end customers, brands can significantly decrease their carbon footprint while still providing fast, efficient service.

Leveraging data for proactive ecosystem management

Data drives modern supply chain ecosystems. With real-time analytics, brands can shift from reactive to proactive operations, anticipating challenges and opportunities before they happen.

Focus on tracking these essential metrics:

- Demand patterns by SKU, region, and channel

- Inventory levels and turnover rates

- Order cycle times and fulfillment speeds

- Transportation costs and delivery performance

- Customer satisfaction metrics

Predictive analytics reveals patterns in this data, helping you make smarter decisions about inventory placement, shipping strategies, and resource allocation. For example, analyzing historical demand alongside weather patterns or social media trends lets you adjust inventory levels ahead of anticipated demand spikes.

Real-time dashboards with automated alerts keep you informed of ecosystem performance and flag potential issues before they become problems.

Real-world applications of advanced technologies

New technologies are revolutionizing supply chain ecosystems with unprecedented visibility and efficiency:

- AI algorithms that accurately predict customer demand

- Blockchain solutions that verify product authenticity

- IoT sensors that monitor product location and condition in real-time

Creating customer-centric supply chain ecosystems

Every supply chain ecosystem should ultimately deliver value to customers. Building your network with customer needs at the center creates meaningful competitive advantage.

Key strategies include:

- Using distributed fulfillment for faster, cheaper delivery

- Applying data analytics to anticipate customer preferences

- Streamlining returns management for seamless post-purchase experiences

- Offering real-time tracking and proactive communication

ShipBob’s strategic fulfillment network enables brands to offer Amazon-like delivery speeds. With facilities in the US, Canada, UK, Europe, and Australia, we position inventory closer to customers, cutting transit times and shipping costs.

Our technology platform provides valuable insights into customer behavior through real-time data on order patterns, product performance, and customer lifetime value, empowering brands to make smarter decisions about inventory, product development, and marketing.

Unlock the power of your supply chain ecosystem with ShipBob

Building a resilient, customer-centric supply chain ecosystem requires strategy, technology, and reliable partners. That’s where ShipBob comes in.

As a leading global fulfillment platform, ShipBob is more than just a 3PL; we’re a strategic partner integrating technology, fulfillment, and analytics to drive your growth.

With our global fulfillment network, you can implement distributed inventory strategies that reduce lead times, cut shipping costs, and enhance customer experience. Our platform connects seamlessly with your systems, providing real-time visibility into inventory, orders, and performance.

Beyond technology, ShipBob’s supply chain experts help you navigate global logistics complexities. We continuously analyze your data to identify optimization opportunities.

Some brands partnering with ShipBob have experienced:

- 25% faster shipping times

- 13% reduction in cart abandonment

- 97% on-time delivery rates

- 63% reduction in fulfillment costs

We’re committed to being a values-driven partner focused on agility, transparency, and sustainability. Together, we build supply chain ecosystems that are efficient, effective, and responsible.

Ready to transform your supply chain?

Contact ShipBob today to start building your future-proof ecosystem.

FAQs about the supply chain ecosystem

Below are more answers to common supply chain ecosystem queries and challenges.

What are the key differences between a supply chain and a supply chain ecosystem?

A supply chain is a linear, sequential process moving goods from suppliers to customers, with each step often managed independently. A supply chain ecosystem is an interconnected network of partners, technologies, and processes working together.

Ecosystems emphasize collaboration and real-time data sharing, enabling agile responses to market changes. While traditional supply chains are often siloed and reactive, ecosystems use advanced technologies to create transparency, adaptability, and resilience across the entire network.

How can small ecommerce brands compete with larger players in building robust supply chain ecosystems?

Partnering with a 3PL like ShipBob gives small brands access to advanced logistics capabilities without massive capital investments. By leveraging our global network, technology integrations, and analytics, smaller brands can effectively compete with larger players.

Smaller brands often have greater agility in adopting new technologies and adapting to customer preferences. By focusing on flexibility, responsiveness, and customer experience, they can differentiate themselves and build loyalty within their ecosystem.

What role does AI play in modern supply chain ecosystems?

AI transforms supply chains by enabling accurate demand forecasting, optimized inventory management, and autonomous decision-making. AI algorithms analyze vast datasets to predict demand patterns, recommend optimal stock levels, and identify potential disruptions before they occur.

AI-powered transportation management systems optimize routes based on real-time conditions, reducing costs and improving delivery times. AI also handles exception management automatically, allowing human workers to focus on higher-value tasks.

How does a distributed fulfillment model reduce environmental impact?

Distributed fulfillment places inventory closer to customers, significantly reducing shipping distances and carbon emissions from transportation.

Data-driven inventory placement minimizes overstocking, reducing waste and costly returns. As brands gain visibility into their supply chain ecosystem, they can continuously improve their environmental performance while balancing business objectives with sustainability goals.

How can brands balance cost efficiency with resilience in their supply chain ecosystem?

Balancing cost efficiency with resilience requires data-driven supply chain management. Analytics help identify potential risks and vulnerabilities, informing decisions about where to invest in redundancy and flexibility.

Strategic partnerships with suppliers, logistics providers, and technology vendors create adaptability without excessive fixed costs. Sharing data and collaborating closely enables quick responses to disruptions and helps capture new opportunities.

How does ShipBob help brands create an integrated supply chain ecosystem?

ShipBob functions as both fulfillment provider and technology partner, connecting all components of your supply chain ecosystem. Our global fulfillment network and software integrations enable distributed inventory strategies with real-time visibility across your entire network.

Our unified platform for order and inventory management consolidates data from multiple sources, providing actionable insights through powerful analytics. This integration helps you make data-driven decisions, optimize operations, and deliver seamless customer experiences.

What metrics should brands track to evaluate supply chain ecosystem health?

To assess ecosystem health, track these key performance indicators:

- On-time in-full (OTIF) delivery rate

- Inventory accuracy and turnover

- Order cycle time and lead time

- Transportation costs and on-time delivery percentage

- Customer satisfaction and Net Promoter Score (NPS)

Regularly comparing these metrics against benchmarks helps identify improvement areas. A comprehensive supply chain dashboard integrating data from multiple sources provides real-time visibility into ecosystem health, enabling proactive management.