Today’s consumers expect perfection when ordering everything – including temperature-sensitive goods. They don’t care about supply chain challenges; they just want products arriving in pristine condition every time.

To keep temperature-sensitive items sellable, you’ll need to store and handle them in a warehousing space that’s temperature-controlled.

But temperature-controlled warehousing goes is more complicated than you might think, and goes far beyond simply “keeping things cold.” It requires precise environmental management, regulatory documentation, specialized training, and seamless integration with your existing fulfillment operations.

In this article, we’ll dive deep into how to leverage temperature-controlled warehousing for your ecommerce business and share best practices for keeping your sensitive products in ship-shape.

What is temperature-controlled warehousing?

Temperature-controlled warehousing is a type of warehousing that’s designed to keep products at specific temperatures to maintain their quality throughout storage and shipping.

Unlike standard warehouses that operate at ambient temperatures, these specialized facilities use advanced cooling, heating, and monitoring systems to create stable environments for different products.

For ecommerce brands selling temperature-sensitive products (like meal kits, artisanal chocolates, probiotics, natural skincare, and more) online, temperature-controlled warehousing has become essential – not optional.

These brands need reliable temperature management to protect product integrity, because the consequences are significant. Customers expect perfect products, and a melted chocolate bar or ineffective supplement doesn’t just lead to returns; it damages brand trust. Temperature-controlled warehousing ensures product quality from warehouse arrival to customer doorstep.

Temperature-controlled vs. climate-controlled vs. ambient

There are different types of temperature-controlled warehouses. Understanding the nuances between them will help you choose the right option for your products.

- Temperature-controlled warehousing: Maintains specific temperature ranges through refrigeration or freezing. These facilities constantly monitor and adjust temperatures to keep products at a very precise temperature (i.e., produce at 35°F or frozen goods at -10°F). It is ideal for food products, medications, and items that degrade outside their optimal temperature zones.

- Climate-controlled warehousing: Manages multiple environmental factors beyond temperature. These facilities regulate humidity, air quality, and sometimes air pressure. This comprehensive approach protects moisture-sensitive products like fine wines, musical instruments, artwork, and certain electronics from warping, corrosion, or damage.

- Ambient warehousing: Provides standard room-temperature storage (59-77°F/15-25°C) using basic HVAC systems. It works well for shelf-stable products like canned goods, sealed supplements, clothing, and most consumer items that don’t need special temperature control.

In practice, brands often need multiple storage types. For example, a skincare and makeup company might require refrigeration for certain serums while keeping mascaras and blushes at ambient temperature. A food company might use frozen storage for steaks, refrigerated storage for produce, and ambient for dried goods.

Your goal should be to find the right type of storage for your products while still controlling costs. Using more specialized storage than necessary wastes money, while inadequate storage risks product quality and customer satisfaction.

5 reasons to leverage a temp-controlled warehouse for ecommerce

For brands shipping temperature-sensitive products, proper storage isn’t just a nice-to-have; rather, it’s a strategic necessity that directly impacts your bottom line and customer loyalty. Here’s why more ecommerce brands are making temperature control a priority.

1. Preserving product integrity

Temperature-controlled warehousing ensures your products arrive at customers’ doors in the exact condition advertised. For sensitive items like probiotics, just a few hours at the wrong temperature can render them ineffective. Natural skincare with active ingredients quickly oxidizes in heat, while premium chocolates develop bloom when improperly stored.

However, if you store products at the correct temperature, your brand can:

- Extend shelf life

- Reduce inventory write-offs

- Maximize your inventory ROI

- Protect your brand’s reputation

2. Meeting compliance requirements

For many products, temperature control is legally required. The FDA, USDA, and other agencies enforce strict guidelines for storing everything from supplements to prepared foods. Non-compliance risks include hefty fines, product recalls, and even criminal charges.

Temperature-controlled facilities must also maintain all documentation required (including any GMP and GSFI certifications), with records proving products stayed within specified temperature ranges.

3. Ensuring positive customer experiences

Nothing damages trust faster than receiving a melted, separated, ineffective, or completely unusable product. In today’s social media landscape, one photo of a temperature-damaged product can quickly go viral. At best, customers will return the goods; at worst, they’ll leave negative reviews that deter future shoppers and never purchase from you again (even from a single bad experience).

On the other hand, when products arrive in perfect condition, customers can leave positive reviews, make repeat purchases, and become brand advocates.

4. Reducing waste and losses

Temperature breaches can be more costly than you’d think. For instance, for a brand shipping $1M in temperature-sensitive products annually, even a 5% loss rate do to temperature compromise means $50,000 in direct losses (not counting disappointed customers and the cost of stockouts and backorders).

Modern monitoring technology helps prevents these losses by alerting staff to potential problems before products are compromised. This protection delivers both financial and environmental benefits by reducing waste, replacement shipments, and unnecessary carbon emissions.

5. Handling seasonal and promotional spikes

Temperature control becomes even more critical during high-demand periods. Whether you’re managing holiday gift sets or running a flash sale on perishable products, flexible temperature-controlled storage helps you capitalize on opportunities without compromising quality.

Professional facilities adapt to seasonal challenges (such as preventing heat damage during summer months or protecting freeze-sensitive products in winter) while scaling capacity to match your demand patterns. This flexibility ensures you never choose between meeting demand and maintaining quality, all while paying only for the space you actually need.

Temperature control ranges explained

Temperature control isn’t just about “keeping things cold”; it’s about maintaining precise conditions that protect product integrity and shelf life. Choosing the wrong storage environment can lead to unnecessary costs or compromised products. Here’s what you need to know about each temperature zone, as well as a deep dive into each type.

| Temperature Zone | Temperature Range | Humidity Control | Ideal For | Key Considerations |

| Ambient | 59-77°F (15-25°C) | Basic HVAC only | Shelf-stable products, packaged snacks, most supplements, canned goods, standard personal care | Most cost-effective option; still requires monitoring during extreme weather |

| Refrigerated | 33-41°F (1-5°C) | Limited | Fresh produce, dairy alternatives, probiotics, temperature-sensitive cosmetics, certain medications | Requires significant infrastructure; consistency is critical; costs 2-3× more than ambient |

| Frozen | -0.4°F to -13°F (-18°C to -25°C) | Limited | Frozen meals, ice cream, certain vaccines, biological samples | Highest energy costs (3-4× refrigerated); specialized equipment and safety protocols needed |

| Specialized Climate | Varies by product | Yes (30-50% RH typical) | Wine, fine chocolates, sensitive electronics, pharmaceuticals | Controls multiple factors (humidity, air quality, light exposure); requires sophisticated monitoring |

Ambient warehouse temperature

Ambient storage (59-77°F/15-25°C) works for most shelf-stable products without heat-sensitive ingredients.

While it’s the most cost-effective option, “ambient” doesn’t mean uncontrolled. Quality facilities still monitor these spaces to prevent temperature spikes during heat waves or drops during winter.

Geographic location also matters. For example, facilities in Phoenix face different challenges than those in Minneapolis. During extreme weather, ambient warehouses may need supplemental heating or cooling to maintain the optimal range. Smart operators use improved insulation and strategic product placement to manage seasonal variations.

Refrigerated or chilled environments

Refrigerated storage maintains consistent temperatures between 33-41°F (1-5°C), preserving items that need cool conditions but would be damaged by freezing. This zone requires significant infrastructure investment, usually including industrial cooling systems, backup generators, redundant monitoring, and specialized insulation.

Temperature consistency is as critical as the temperature itself. Even a two-degree fluctuation can render products like insulin or skincare products ineffective. Modern facilities use sophisticated airflow management, rapid-close doors, air curtains, and strict protocols to maintain stability throughout the space.

Frozen or sub-zero storage

Frozen storage (-0.4°F to -13°F/-18°C to -25°C) preserves everything that needs to be stores at sub-zero temperatures, such as ice cream and certain vaccines.

Frozen environments present unique challenges: equipment must withstand extreme cold, workers need specialized protective gear, and even warehouse floors require special treatment to prevent frost damage.

Product handling also differs significantly in frozen environments. Items become more brittle, condensation forms during temperature transitions, and packaging must withstand both extreme cold and thermal shock. With energy costs 3X-4X higher than refrigerated storage, efficient inventory management becomes even more critical.

Specialized climate parameters

Some products require precise environmental conditions beyond temperature. Wine, for instance, needs specific humidity to prevent cork drying, and electronics require low humidity to prevent corrosion.

These specialized environments use sophisticated building management systems that continuously monitor and adjust multiple parameters simultaneously. When outdoor conditions change or doors open, the system immediately reacts and compensates to maintain the exact environment required.

For ecommerce brands with specialized climate needs, finding a fulfillment partner who understands these complexities is essential. You need a partner that can maintain precise conditions, document control for compliance, and still deliver the speed your customers expect.

6 best practices for temperature-controlled warehousing

Successful temperature-controlled warehousing goes beyond basic refrigeration. Here are six strategies to leverage in your temperature-controlled warehouses to protect product integrity while maximizing operational efficiency.

1. Real-time monitoring & sensors

Modern monitoring systems provide complete visibility and early warnings before problems affect your products.

- Temperature mapping: Identify hot spots and cold zones throughout your warehouse before placing inventory.

- Strategic sensor placement: Install wireless sensors at different heights, near doors, and throughout each zone to transmit data frequently.

- Multi-channel alerts: Set tiered warning thresholds that notify staff via multiple channels when temperatures approach critical levels.

- Digital documentation: Replace paper logs with electronic records that provide tamper-proof temperature history for audits.

2. Energy-efficient equipment & layout

Smart infrastructure choices maintain precise temperatures while controlling operational costs.

- High-performance insulation: Use modern materials and seal all potential leak points to maintain temperature stability.

- Door management: Install rapid-close doors, strip curtains, and air curtains to minimize temperature loss during access.

- Strategic layout: Minimize travel between temperature zones and create buffer areas between different environments.

- LED lighting: Replace heat-generating fixtures with LEDs that run cooler and provide better visibility.

3. Worker safety & training

Well-equipped and trained staff are essential for maintaining temperature integrity.

- Proper gear: Provide temperature-appropriate clothing, footwear, gloves, and face protection.

- Smart scheduling: Limit cold exposure time and provide warm break areas to prevent cold stress.

- Comprehensive training: Teach safety protocols, emergency procedures, and how daily actions affect temperature control.

- Ongoing education: Schedule regular refreshers to reinforce best practices and introduce new techniques.

4. Regulatory compliance

Systematic documentation protects both products and your business from regulatory issues.

- HACCP implementation: Create detailed plans with temperature control points, monitoring protocols, and corrective actions.

- GMP compliance: Maintain training records, equipment logs, and investigation procedures for any deviations.

- Third-party certification: Pursue industry standards like SQF or BRC to verify your processes independently.

- Audit readiness: Keep organized records and ensure staff understand their roles during inspections.

5. Managing peak demand

Plan for high-volume periods when increased activity can strain temperature control systems.

- Data-driven planning: Use historical patterns to forecast capacity needs and prepare resources accordingly.

- Flexible solutions: Arrange temporary storage options and adjust schedules to spread volume evenly.

- Equipment backup: Keep spare parts on hand, establish emergency service contracts, and test backup systems regularly.

- Crisis preparation: Develop specific response plans for different failure scenarios during peak periods.

6. Data analytics

Transform temperature data into actionable insights that improve operations and reduce costs.

- Pattern recognition: Analyze trends to identify potential equipment failures and optimize maintenance timing.

- Predictive capabilities: Use machine learning to forecast issues and determine optimal product placement.

- System integration: Connect temperature monitoring with inventory systems to enable FEFO routing and prevent shipping compromised products.

- Cost optimization: Use data to identify energy savings, justify equipment investments, and maximize profitability.

Industries that rely on temperature-controlled logistics

For some industries, temperature control is absolutely essential. Here’s how different kinds of businesses leverage temperature-controlled logistics to protect product integrity and customer trust.

Food & beverage

As the largest segment of temperature-controlled logistics, food brands face increasingly strict safety regulations alongside rising consumer expectations. Each product category demands precise temperature management:

- Fresh produce: 32-45°F (leafy greens at 32-34°F, tomatoes at 45-50°F)

- Dairy and meats: 33-38°F

- Frozen foods: 0°F or below

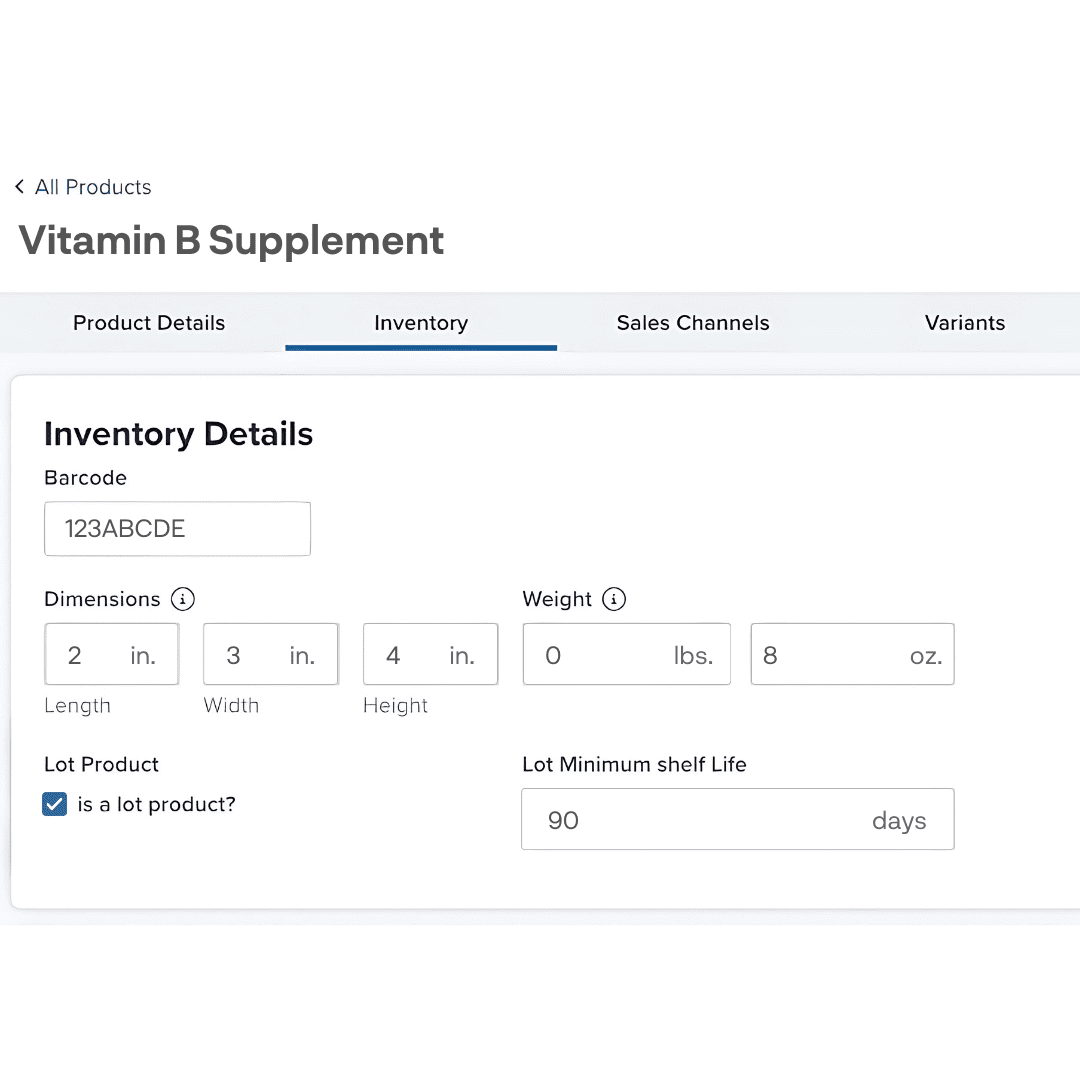

“Many of our products have expiration dates, so it’s incredibly important for us to track and maintain inventory freshness – and ShipBob’s lot control features make that really easy. When we send new inventory to ShipBob, all we have to do is mark it as a lot product in the ShipBob dashboard and list the lot number and expiration date for each lot on the warehouse receiving order (WRO). From there, ShipBob handles receiving and stores each lot separately for trackability and so there’s no confusion when it’s time to pick.

We use the FEFO (First Expired, First Out) method of inventory management, meaning that we want to prioritize picking inventory units that have the earliest expiration date. Thankfully, ShipBob’s default logic is designed to always ship items with the nearest listed expiration date first, so that works out perfectly. At our scale, it would be impossible to manually check the expiration date of every single unit we ship, so leveraging ShipBob’s lot capabilities gives us much more peace of mind.”

Neil Blewitt, SVP of Operations at Bloom Nutrition

Pharmaceuticals & nutraceuticals

When a temperature excursion can mean life or death, precision becomes non-negotiable. Pharmaceutical storage must comply with strict FDA regulations, including:

- Drug Supply Chain Security Act requirements for temperature tracking.

- Good Distribution Practices mandating validated temperature systems.

- Product-specific requirements ranging from room temperature (68-77°F) to ultra-cold storage (-80°C).

Cosmetics & beauty

The clean beauty movement has transformed cosmetic storage needs. Without synthetic preservatives, many formulations now require refrigeration.

- Emulsions separate when exposed to heat, ruining expensive creams

- Active ingredients like retinol and vitamin C rapidly degrade at higher temperatures

- Even color cosmetics can melt, separate, or crack from temperature fluctuations

This has created entirely new categories of “fresh” beauty products requiring consistent cold chain management from production through delivery.

“We heavily rely on the ShipBob team to help with inventory planning, distribution, and placement. Our team really leans on ShipBob for logistics and fulfillment expertise because we don’t have that internally.”

Kayleigh Christina, Co-Founder and CMO of CLEARSTEM

Electronics & specialty goods

Temperature control extends far beyond food and pharmaceuticals. Lots of everyday products require specific temperatures to remain in good condition, such as:

- Batteries: Lithium-ion batteries suffer permanent capacity loss at high temperatures.

- Displays: LCD/OLED screens can get dead pixels from heat or crack from extreme cold.

- Specialty items: Fine wines, wooden musical instruments, adhesives, and even certain textiles require climate control to prevent degradation.

As consumers continue to purchase temperature-sensitive products online, ecommerce brands must adopt sophisticated temperature control strategies or risk damaged products and lost customer trust.

“Some of our products are categorized as dangerous goods, so fulfillment and shipping can be a challenge for any channel, but B2B especially. Our previous 3PLs really struggled with handling and shipping our B2B orders with dangerous goods. ShipBob has done a significantly better job getting our B2B dangerous goods shipped via air, sea, and road, as well as getting the complicated documentation completed properly.

A lot of fulfillment providers say they can do B2B, but they’re really after your DTC business. They piggyback on the B2B business and don’t actually know what they’re doing and there are a lot of mistakes. ShipBob has been able to deliver on both aspects of our business, beat SLAs, and work closely with us so our orders are going out exactly how we want them to. Our fulfillment is in a really good place.”

Callum Jones, Director of Operations & Marketplace, and Rachel Hicks, Operations Manager at Hairburst

How to integrate temperature-controlled storage with DTC ecommerce

Temperature control for DTC ecommerce isn’t the same as traditional cold storage. You’re not shipping entire pallets on predictable schedules; rather, you’re fulfilling individual orders that need to get where they’re going fast.

So if you need temperature-controlled storage for inventory, you’ll have to master two aspects of your logistics in particular: your inventory management and geographic footprint.

Seamless inventory management

On top of inventory counts, your warehouse management system must manage temperature requirements, expiration dates, and special handling needs.

For orders the contain items that have different temperature needs (for example, an order that asks for a refrigerated probiotics with a bag of potato chips), your system should recognize each product’s storage requirements and create efficient picking paths across different temperature zones.

Good management means tracking expiration dates, preventing the sale of expired products , and setting reorder points that account for the longer lead times refrigerated goods often require.

Perishable products demand real-time inventory updates to prevent selling items that have expired or experienced temperature excursions.

Fast shipping & location strategy

Speed is crucial, because every hour in transit increases risk for temperature-sensitive products.

Strategic warehouse placement significantly reduces both transit times and costs. While shelf-stable products work fine with bi-coastal warehousing, perishable goods need more regional fulfillment locations to keep delivery distances short.

The cost benefits are clear: shipping frozen products from LA to NYC might cost $30-40 via next-day air, compared to just $8-10 for two-day ground shipping from nearby New Jersey. These savings quickly outweigh the complexity of managing multiple inventory locations.

Last-mile delivery also requires special attention, including clear delivery instructions and customer notifications. Many brands now use smart coolers, scheduled delivery windows, or local cold storage pickup options to ensure products arrive in perfect condition.

How ShipBob supports temperature-controlled warehousing and fulfillment

For ecommerce brands shipping temperature-sensitive products, managing your own cold storage facility is both expensive and a logistical nightmare that diverts focus from what matters: growing your brand.

That’s why many brands opt to partner with an expert like ShipBob temperature-sensitive storage and fulfillment. Here’s how ShipBob could solve your temperature control challenges, while you focus on scaling your business.

Specialized facilities for conditional items

Temperature-sensitive products need special treatment, which is why ShipBob classifies them as “conditional items” requiring approval before entering our network. Our team evaluates your specific requirements, from temperature specifications to regulatory needs, to make sure that we can maintain your products’ integrity.

Once approved, your products flow into our air conditioned and heated facilities to ensure that products are stored in the right conditions, with staff trained in cold chain management and enhanced protocols that protect quality from receiving to delivery. We’ve built a system where temperature control isn’t an afterthought, but rather integrated into every touchpoint your products experience.

Distributed fulfillment network

Perishable products and long shipping distances don’t mix. ShipBob’s nationwide fulfillment network positions your inventory closer to customers, dramatically reducing transit times when every hour matters. This strategic approach also means you can often use standard ground shipping to deliver even temperature-sensitive products in 2 days.

During peak seasons or promotions, ShipBob’s distributed network delivers even more value. Instead of overwhelming a single facility, orders will automatically route to the optimal location with available inventory. This ensures quick delivery while protecting against local disruptions that could compromise temperature control.

Real-time visibility and compliance

ShipBob’s dashboard delivers the visibility temperature-sensitive products demand. Brands can track inventory across temperature zones, manage expiration dates with FEFO picking, and maintain detailed lot records for traceability.

From receiving to delivery confirmation, you’ll know exactly where your temperature-sensitive products are and how they’re being handled. This transparency prevent problems and builds the confidence to scale your temperature-sensitive product lines without scaling your headaches.

Industry-specific expertise

Temperature-controlled fulfillment isn’t one-size-fits-all. From beauty to health, F&B to wellness, ShipBob works with dozens of brands across temperature-sensitive verticals to match their fulfillment needs.

“We quadrupled our order volume this year, and because our fulfillment and shipping costs have gotten so much cheaper, we’ve been able to support that scale.”

Matt Crane, Co-Founder and Chief Science Officer at Semaine Health

“When we first started with ShipBob, we were very small, so we didn’t have deep pockets. Like a lot of ecommerce brands in the health and beauty space, we were at a place where paying an extra pound or so per order for fulfillment was a big deal – but ShipBob’s service has absolutely been worth it. Everyone talks about keeping fulfillment in-house, but it’s absolutely worth the leap of faith – ShipBob has so much to offer.”

Kelly Bond, Operations Manager at Elle Sera

“We’ve scaled so much, and there have been zero hiccups in fulfillment with ShipBob. Running your own warehouse, you have to go out and hire very experienced people, invest in equipment, build in automation – and often, you’re wasting a lot of time, energy, resources, and human capital for a sub-par result. Why do that when a partner like ShipBob exists, and makes fulfillment so easy at a fair price?”

Tyler McCann, Co-Founder of Taste Salud

For more information on how ShipBob can help your brand achieve temperature-controlled warehousing that scales, click the button below to get in touch.

FAQs about temperature-controlled warehousing

Here are answers to common questions about temperature-controlled warehousing for ecommerce businesses.

How do I ensure compliance with FDA, OSHA, or other regulations?

First, identify which regulations apply to your products. FDA rules for food differ from OSHA safety standards for cold storage. Keep detailed temperature logs, create clear procedures for temperature excursions, and organize all documentation for easy access during inspections.

Partner with a fulfillment provider experienced in compliance requirements. Conduct regular internal audits to catch

Can ShipBob handle products requiring strict temperature regulation?

ShipBob handles certain temperature-controlled products (food and beverages, dietary supplements, etc.) through specialized fulfillment centers. These are considered conditional items requiring written approval before entering our network.

To get approved, submit your product details, temperature requirements, and compliance documentation. While we don’t currently offer frozen storage, we provide refrigerated options for products needing consistent cool temperatures. For ultra-cold or frozen storage needs, we can recommend specialized partners.

How do sensors and real-time monitoring prevent product spoilage?

Wireless sensors strategically placed throughout storage areas continuously track temperature conditions. When readings go outside acceptable ranges, the system immediately alerts staff to take action before products are compromised, whether that means adjusting settings, relocating inventory, or checking equipment.

This continuous monitoring creates a complete audit trail proving products stayed within required specifications. Advanced systems use data analytics to predict potential issues before they happen, such as identifying equipment that needs maintenance before it fails.

How can brands balance costs and compliance without compromising quality?

Optimize your warehouse layout by grouping products with similar temperature requirements, using thermal curtains between zones, and improving inventory turnover to reduce storage time. The investment in proper temperature control pays off through reduced product loss, fewer customer complaints, and avoided compliance penalties.

Partner with a 3PL that already has temperature-controlled infrastructure instead of building your own. This spreads costs across multiple clients while giving you access to professional equipment and expertise. Storing inventory closer to customers also reduces shipping distances, maintaining product quality while lowering transportation costs.

What specialized packaging is needed for shipping temperature-sensitive products?

Your packaging needs depend on your product’s temperature requirements and transit times. For refrigerated items with 1-2 day shipping, insulated box liners with gel packs usually work. Products with longer transit times or stricter requirements may need specialized coolers with dry ice or phase change materials.

Consider eco-friendly options like recycled denim insulation or plant-based foam alternatives. Always validate your packaging through testing — ship samples with temperature loggers to different locations across seasons to ensure products arrive at the right temperature. Many packaging suppliers offer testing services to help you choose the right solution.