Verified & Reviewed

Last updated on December 12, 2025 Written By Rachel Hand

Last updated on December 12, 2025 Written By Rachel Hand

Subscribe for More

When you’re managing inventory across multiple SKUs, suppliers, or locations, staying organized isn’t optional; it’s absolutely essential.

That’s where batch tracking comes in. This powerful inventory management method allows ecommerce businesses to group and trace products based on shared attributes like production date, expiration, or origin, making it easier to maintain quality, manage recalls, reduce waste, and stay compliant. Whether you’re shipping perishables, cosmetics, supplements, or high-regulation goods, batch tracking helps ensure that the right items get to the right customers at the right time.

In this guide, we’ll break down how batch tracking works, when to use it, which systems support it best, and how to build an inventory strategy that scales with your growth.

What is batch tracking?

Batch tracking is a method of monitoring and managing groups of products that were manufactured together under the same conditions, and tracing them as they move through the supply chain.

At its core, batch tracking plays a fundamental role in product traceability, which is the ability to track an item’s journey through the supply chain – from production to the end customer.

In batch tracking, ecommerce brands organize their inventory based on production runs, manufacturing dates, or other shared characteristics. By assigning unique identifiers to each batch, businesses can quickly identify and location all the products in a certain batch in the event of a recall, quality issue, or customer inquiry.

While batch tracking is relevant to nearly all industries, it is particularly essential for businesses dealing with perishable or regulated products, such as food, pharmaceuticals, cosmetics, and supplements. In these sectors, batch tracking is often a legal requirement and subject to strict industry regulations and quality control standards.

Batch tracking vs. lot tracking vs. serial tracking

Although the terms “batch tracking,” “lot tracking,” and “serial tracking” are often used interchangeably, there are subtle differences between them.

- Batch tracking typically refers to the monitoring of a specific group of identical items that were produced together in a single manufacturing run.

- Lot tracking can encompass multiple batches that are grouped together for logistics or inventory management purposes.

- Serial tracking takes this concept a step further by assigning unique identification numbers to individual items within a batch or lot. This approach is most commonly used for high-value products, such as electronics or luxury goods, where each item needs to be tracked separately for warranty, service, or authentication purposes.

To illustrate these differences, consider a cosmetics manufacturer producing a new line of lipsticks. Each production run of lipsticks in a specific shade would be considered a batch, while a shipment containing multiple batches of different shades could be tracked as a lot. If the manufacturer chose to assign unique serial numbers to each individual lipstick, they would be employing serial tracking.

Why your business needs a batch tracking system

Implementing a formal batch tracking system can create a significant competitive advantage for your ecommerce business. Here are some of the key benefits of implementing batch tracking in your inventory management.

Enhanced quality control and compliance

Batch tracking enhances product quality control and regulatory compliance. Maintaining detailed records of each batch’s production, storage, and distribution history helps ensure that your products meet the strictest quality standards and comply with relevant regulations.

For example, if you sell food products, you’ll need to adhere to FDA guidelines and maintain traceability throughout your supply chain. Batch tracking documents every step of the process, from ingredient sourcing to final packaging, providing a clear audit trail for inspections and certifications.

Similarly, if you operate in the cosmetics or pharmaceutical industries, batch tracking is essential for meeting GMP (Good Manufacturing Practice) requirements. By monitoring each batch’s production conditions, expiration dates, and quality control measures, you can demonstrate compliance and mitigate the risk of costly penalties or product recalls.

Efficient recalls and returns management

No ecommerce business wants to face a product recall, but it’s wise to be prepared for the worst. In the event of a recall, having a robust batch tracking system can be the difference between a targeted, efficient response and a broad, costly ordeal.

With precise batch-level data, you can quickly identify the specific products affected by a recall and isolate them across your supply chain. This targeted approach minimizes the financial and reputational damage of a recall by limiting the scope of the event and demonstrating your commitment to customer safety.

Inventory accuracy and reduced waste

Effective batch tracking can also help you optimize your inventory management and reduce waste. By monitoring the expiration dates and shelf life of each batch, you can ensure that your products are sold in the appropriate order and minimize the risk of obsolescence.

This is particularly important for businesses that deal with perishable goods or products with limited shelf lives. By implementing inventory rotation strategies like FIFO (First-In-First-Out) or FEFO (First-Expired-First-Out), you can ensure that your oldest stock is sold first, reducing the likelihood of waste due to expiration.

Batch tracking also enables you to maintain accurate inventory counts and avoid the costs associated with overstocking or stockouts. With real-time visibility into your batch-level inventory, you can make informed decisions about reordering and production, ensuring that you always have the right products in the right quantities to meet customer demand.

Batch inventory management systems: key features and capabilities

In the early days of inventory management, many businesses relied on manual methods like spreadsheets and physical records to track batches. While these approaches can work for small-scale operations, they quickly become cumbersome and error-prone as a business grows.

Today, automated batch inventory management systems have become the gold standard for ecommerce brands looking to maintain tight control over their products. These advanced solutions offer a range of features and capabilities that can transform the way you manage your inventory. Some of the most critical elements to look for include:

- Real-time batch visibility: The ability to monitor your batch inventory levels, locations, and status at a glance is crucial for making informed decisions and responding quickly to potential issues.

- Expiration date tracking: Automated systems can help you keep a close eye on expiration dates, alerting you when products are nearing the end of their shelf life and helping you prioritize order fulfillment accordingly.

- Low inventory and expiration alerts: Proactive notifications when batch quantities run low or expiration dates approach can help you avoid stockouts and minimize waste.

- Reporting and analytics: Robust reporting capabilities allow you to spot trends, identify inefficiencies, and make data-driven improvements to your batch management processes.

- Mobile accessibility: In today’s fast-paced ecommerce environment, the ability to manage your batches from anywhere, at any time, is a significant advantage.

Integrations with Shopify, Amazon, and other platforms

Even the most advanced batch inventory management system is only as effective as its ability to integrate with your other ecommerce tools and platforms. Seamless data flow between your sales channels and inventory systems is essential for maintaining accuracy, efficiency, and customer satisfaction.

- Shopify: For businesses selling on Shopify, there are a variety of apps and extensions available that support batch tracking. These tools can help you synchronize your batch data across your Shopify store, warehouse locations, and fulfillment partners, ensuring that everyone has access to the most up-to-date information.

- Amazon: Amazon sellers will need to be familiar with the platform’s specific batch tracking requirements and ensure that their inventory management system is capable of meeting those standards. This may involve using Amazon’s built-in batch tracking tools or integrating a third-party solution that can communicate with Amazon’s systems.

- Multichannel: With the right multichannel synchronization strategies in place, it’s possible to keep your batch information accurate and up-to-date across all of your sales platforms. This may involve using a centralized inventory management system that can integrate with each of your channels, or working with a fulfillment partner who can handle the complexities of multichannel batch tracking on your behalf.

Scaling for multi-warehouse and omnichannel sellers

As your ecommerce business grows, you may find yourself storing inventory in multiple warehouses or fulfillment centers across the country or even around the world. This can create unique challenges when it comes to maintaining batch integrity.

This means you’ll need a batch inventory management system that can:

- Provide real-time visibility into your inventory levels and locations across all of your facilities.

- Maintains clear protocols for transferring batches between locations when necessary to ensure that all of your facilities are adhering to the same standards for batch labeling, storage, and rotation.

- Gives you the ability to make rapid adjustments to your allocation strategy as needed, or allocate certain batches to specific sales channels based on factors like expiration dates, product freshness, or customer preferences.

Ultimately, the key to scaling your batch tracking is to work with partners and systems that can provide the flexibility, visibility, and control you need to make informed decisions and keep your products flowing smoothly. With the right provider and the right tools, you can continue to grow your batching – and your business – with confidence.

Step-by-step guide to implementing batch tracking

Implementing batch tracking can seem daunting – but with the right approach, it can be a smooth and rewarding process. Whether you’re a small business just starting out or a large enterprise looking to optimize your operations, this step-by-step guide will help you navigate the implementation process and unlock the full potential of batch tracking.

✅ Assess current inventory processes

Before diving into implementation, it’s essential to take stock of your current inventory management practices. This will help you identify areas for improvement and ensure that your batch tracking system is tailored to your specific needs.

Start by conducting a thorough audit of your existing systems and processes. In doing so:

- Look for gaps in your current tracking methods, such as manual record-keeping or lack of visibility into batch-level data.

- Identify any compliance risks or inefficiencies that could be addressed through better batch tracking.

- Quantify the costs associated with your current batch management issues (such as waste due to expired products, labor costs for manual tracking, or potential fines for non-compliance) to build a strong business case for implementing a more robust batch tracking system.

- Involve key stakeholders from across your organization in the assessment process, including representatives from warehouse operations, quality control, compliance, and IT to earn buy-in and set the transition up for success.

🎯 Choose the right method or software solution

Once you have a clear understanding of your current processes and future needs, it’s time to choose the right batch tracking method or software solution. The best approach will depend on factors like the size and complexity of your business, your budget, and your long-term growth plans.

For smaller businesses with limited SKUs and simple operations, manual tracking methods like spreadsheets may be sufficient. However, as your business grows and your inventory becomes more complex, you’ll likely need to transition to a more automated solution.

Many ecommerce platforms, such as Shopify and Amazon, offer built-in features for batch tracking. These can be a good option for businesses that primarily sell through a single channel and don’t require advanced functionality. If you sell across multiple channels or have more complex needs, consider investing in a dedicated inventory management software or enterprise resource planning (ERP) system from the jump.

When evaluating potential solutions, consider factors like scalability, ease of use, and integration capabilities. Look for a system that can grow with your business and adapt to changing needs over time. Think about the total cost of ownership, including any upfront investments, ongoing subscription fees, and potential integration expenses.

🔌 Integrate with ecommerce platforms and 3PLs

Once you’ve selected a batch tracking solution, the next step is to integrate it with your ecommerce platforms and third-party logistics (3PL) providers. This is critical for ensuring that batch information flows seamlessly across your supply chain and that all stakeholders have access to accurate, up-to-date data.

Start by mapping out your data flows and identifying the key integration points between your systems. Work with your software vendor or IT team to establish the necessary API connections and ensure that data is being mapped correctly between fields.

If you work with a 3PL like ShipBob, you’ll also need to ensure that your batch tracking data is being communicated effectively to your fulfillment partner. This may involve setting up custom integrations or working with your 3PL to establish standardized data exchange protocols.

Before going live with your new batch tracking system, be sure to conduct thorough testing of all integrations. This will help you identify any issues early on and ensure a smooth rollout.

👷 Train your team and establish SOPs

Effective batch tracking relies on consistent, accurate data input from across your organization. Make sure everyone is on the same page by providing comprehensive training and establishing clear standard operating procedures (SOPs).

Your batch tracking SOPs should cover all key aspects of the process, from receiving and labeling to inventory movement and expiration monitoring. Be sure to include detailed instructions for each step, as well as any specific compliance requirements or quality control checkpoints.

🔎 Monitor, maintain, and optimize

Implementing a batch tracking system is not a one-and-done effort. To realize the full benefits, you’ll need to continuously monitor your processes, maintain your systems, and look for opportunities to optimize over time. This includes:

- Establishing key performance indicators (KPIs) to track the effectiveness of your batch management processes, like batch accuracy rate, expiration-related waste percentage, time to isolate batches, and recall response time.

- Conducting regular audits of your batch tracking processes to ensure that SOPs are being followed, data is being recorded accurately, and issues are caught early on and prevent them from snowballing into larger problems.

- Fostering a culture of continuous improvement within your organization, where team members are encouraged to suggest ideas for streamlining processes or enhancing system capabilities.

Industry-specific batch tracking considerations

While the core principles of batch tracking remain consistent across industries, there are some unique considerations and requirements depending on the types of products a business sells.

Let’s explore some of the key batch tracking considerations for three highly regulated industries: food and beverage, pharmaceuticals and supplements, and cosmetics and personal care.

🍎 Food and beverage

For food and beverage manufacturers, batch tracking is not just a best practice; it’s a legal requirement. The FDA’s Food Safety Modernization Act (FSMA) mandates that all food producers maintain detailed records of their products’ journeys from farm to fork, including batch-level data on ingredients, processing conditions, and distribution.

To comply with these requirements, food and beverage companies must:

- Maintain meticulous documentation for each batch they produce, including records of supplier lot numbers for incoming ingredients and batch numbers for finished products.

- Be able to quickly trace any potentially contaminated products back to their source in the event of a recall.

- Pay close attention to allergen management and temperature monitoring, and segregate products containing common allergens like nuts, dairy, or soy and to alert staff if any cross-contamination occurs.

- Use temperature monitoring is for perishable products to ensure they remain safe and high-quality throughout their shelf life.

💊 Pharmaceuticals and supplements

Like food and beverage, the pharmaceutical and supplement industries are subject to strict batch tracking requirements as part of Good Manufacturing Practices (GMP) regulations. These requirements are designed to ensure the safety, efficacy, and consistency of drug products.

Under GMP regulations, pharmaceutical and supplement manufacturers must maintain detailed batch production records that include information on raw materials, processing steps, and quality control testing. Batch numbers must be assigned to each production run and used to track products through the supply chain.

In addition to these general requirements, there are some specific considerations for different types of pharmaceutical products. For example, prescription drugs are subject to more stringent tracking requirements than over-the-counter products, and may require additional documentation around expiration dates and disposal.

Supplement manufacturers must be particularly diligent about ingredient traceability and purity. With the globalization of the supplement supply chain, it’s critical to have robust batch tracking systems in place to ensure that all raw materials are sourced from reputable suppliers and meet quality standards.

💄 Cosmetics and personal care

While the cosmetics and personal care industry is not as heavily regulated as food and pharmaceuticals, there are still important batch tracking considerations for these products. In particular, the FDA requires that cosmetic manufacturers follow Good Manufacturing Practices (GMP) to ensure the safety and quality of their products.

Under cosmetic GMP guidelines, manufacturers must maintain batch production records that include information on raw materials, processing steps, and quality control testing. Batch numbers must be assigned to each production run and used to track products through the supply chain.

There are also a few unique considerations for cosmetics and personal care brands, such as:

- Preservative efficacy testing: Because many cosmetic products contain water, they are susceptible to microbial growth and spoilage over time. To ensure that products remain safe and stable throughout their shelf life, manufacturers must conduct preservative efficacy testing on each batch and maintain detailed records of the results.

- Ingredient traceability: With consumers increasingly interested in the sourcing and sustainability of their personal care products, it’s important to have robust batch tracking systems in place to ensure that all ingredients are ethically and responsibly sourced.

- International regulations: Finally, cosmetic companies that sell their products internationally need to be aware of the regulatory requirements in each market they serve. Different countries may have their own labeling, testing, and documentation requirements that must be met in order to legally sell products.

How 3PL partnerships can simplify batch tracking

For many ecommerce businesses, managing batch tracking in-house can be a complex and resource-intensive process – especially for companies that sell a wide range of products in a wide range of places.

For these brands, partnering with a third-party logistics (3PL) provider can be an effective way to simplify batch tracking and ensure compliance with industry regulations.

Some of the key advantages of working with a 3PL are:

- Expertise: Many 3PLs specialize in serving specific industries, such as food and beverage or pharmaceuticals, and have deep knowledge of the unique regulatory requirements and best practices for those sectors.

- Infrastructure: By outsourcing batch tracking to a 3PL, businesses can avoid the need to invest in expensive software systems or hire additional staff to manage these processes in-house. Instead, they can rely on their 3PL partner to handle all aspects of batch tracking, from receiving and labeling to inventory management and recall support.

- Standardization: For businesses that store inventory in multiple warehouses or distribution centers, maintaining accurate batch tracking data can be a challenge. Working with a 3PL that has a standardized batch tracking system across all of its facilities ensures a brand’s products are being handled consistently.

Of course, not all 3PLs are created equal when it comes to batch tracking capabilities. When evaluating potential partners, it’s important to look for a provider that:

- Has experience in your specific industry.

- Can demonstrate a track record of success in managing complex batch tracking processes.

- Offers technology systems are compatible with your own, with clear processes in place for data sharing and communication.

Why choose ShipBob for batch inventory management

At ShipBob, we understand how important it is for ecommerce businesses to have effective batch tracking. That’s why we’ve built our fulfillment platform around a robust lot management system that enables our clients to achieve unprecedented visibility and control over their inventory.

Global fulfillment network

With over 60 fulfillment centers across six countries, we can help businesses of all sizes streamline their supply chains and reach customers faster. Our inventory storage, receiving, fulfillment, and shipping processes are standardized across all of our facilities, our clients can be confident that their products are being handled consistently and accurately at every stage of the fulfillment process.

“The beautiful thing about ShipBob is everything was connected. I could log on to our ShipBob account and see everything in one place, no matter if I’m looking at our facility in Kankakee, IL, or the ShipBob fulfillment centers in Canada or Europe. It was all the same system. I didn’t have to learn various different platforms or deal with support representatives at different companies. Plus, if we experience any issues with syncing orders between systems, there’s one place we go to reconcile it. ShipBob is connected to our ERP, NetSuite, which is our single source of truth. Now we only have one place to troubleshoot and resolve potential issues across all logistics.”

Adam LaGesse, Global Warehousing Director at Spikeball

Lot management capabilities

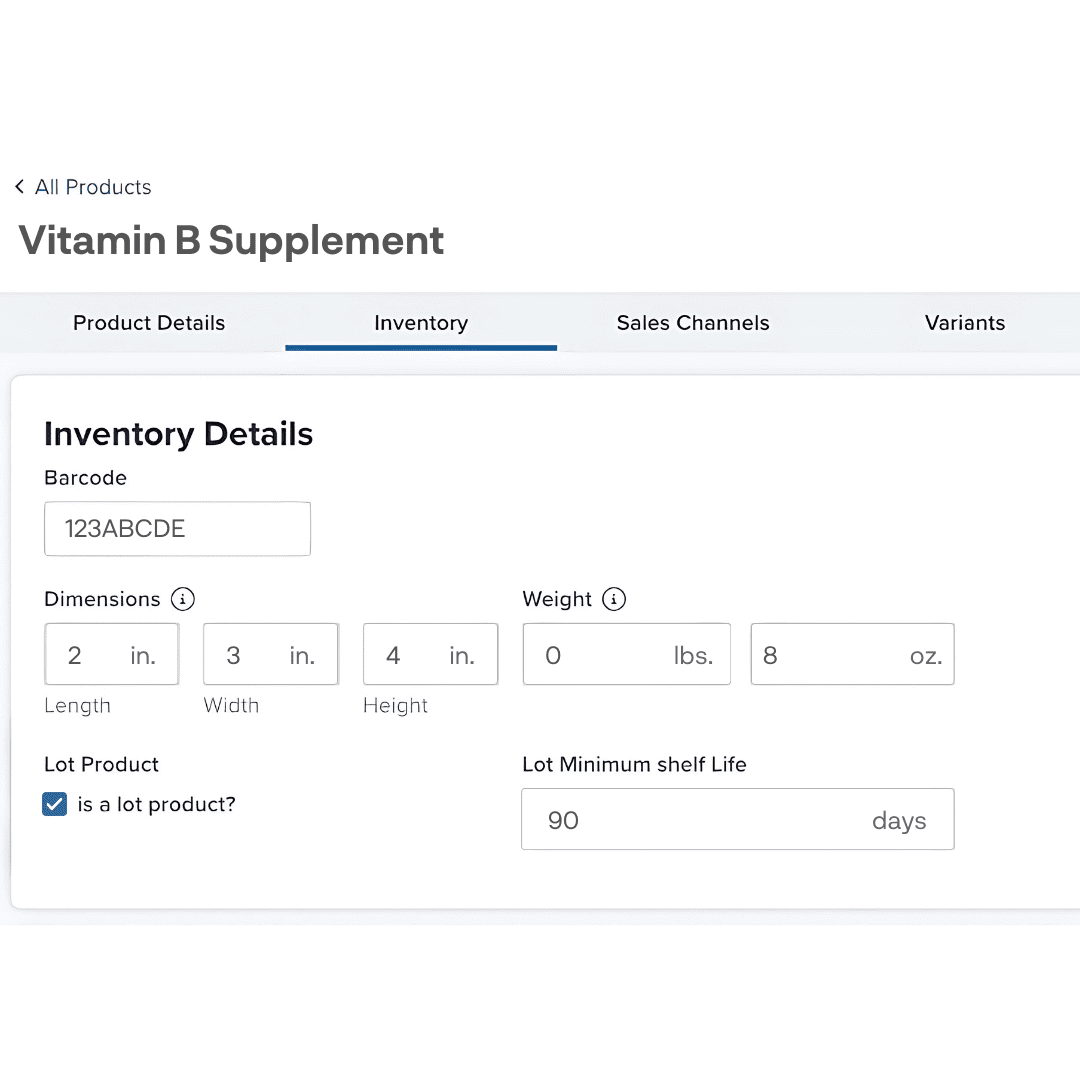

Our lot management technology is designed to support batch-level visibility and traceability from the moment inventory arrives at our fulfillment centers. We work with our clients to establish clear labeling and documentation requirements for each batch, ensuring that all necessary data is captured and recorded in our system.

“Using ShipBob’s lot management capability, we’re able to check our lot numbers and essentially keep the warehouse accountable – but I’ve not had to step in to make sure that we’re sending out the right products, because everything is very automated. It’s been a big time-saver for me and my team, and made managing the whole lot aspect of our business so much easier. We actually expected to throw more man hours into managing lots, but that hasn’t been the case because everything’s seamless.”

Oscar Gutierrez, Operations Fulfillment Manager at goPure

Real-time inventory management

Once inventory is received and checked in, our software enables us to track each batch separately and monitor key data points like expiration dates and storage conditions.

This level of granularity empowers our clients to make informed decisions about inventory allocation, rotation, and disposal, reducing waste and ensuring that customers always receive the freshest possible products.

Recall preparation and SOPs

ShipBob offers robust recall management support, leveraging our batch tracking capabilities to quickly identify and isolate affected products in the event of a quality issue or safety concern.

Our team of experts can guide clients through every step of the recall process, from customer communications to product disposal, minimizing the impact on their business and reputation.

Seamless integration

Perhaps most importantly, ShipBob’s batch tracking capabilities are fully integrated with our clients’ ecommerce platforms, providing a seamless and efficient data flow from order placement to fulfillment. We offer direct integrations with popular platforms like Shopify and Amazon, as well as custom API solutions for businesses with unique needs.

“ShipBob has an impressive catalog of integrations that we can play around with, and the ones we currently use have been incredible. ShipBob’s integration with Gorgias works amazingly well. We use Prediko, which is connected through Shopify, for inventory management, and the integration is really smooth. It allows us to firm up our supply chain and safeguard our inventory holding. It’s been beneficial to have a direct link from the warehouse to our inventory management system.”

Connor Stewart, Head of Operations + Impact at ARTAH

For more information about how ShipBob can help your brand master batch tracking, click the button below to get in touch.

FAQs about batch inventory tracking

Here are answers to come of the most common questions about batch inventory tracking.

What if I store inventory in multiple warehouses?

Managing batch information across multiple storage locations can be challenging, but it’s essential for maintaining traceability and efficiency. You’ll need a system that provides real-time visibility into batch locations, quantities, and expiration dates across all of your facilities.

Establish clear protocols for batch transfers between warehouses. This includes documenting batch information on packing slips, maintaining accurate records of batch movements, and ensuring that receiving warehouses properly update their inventory records.

Partnering with a professional supply chain enablement partner like ShipBob can simplify multi-warehouse batch tracking. ShipBob’s fulfillment network operates under a single WMS, providing merchants with real-time batch-level visibility across all of their inventory, regardless of location.

How do I handle returns or disposal when using batch tracking?

When a customer returns a product, the first step is to identify which batch or lot the item belongs to. This information should be clearly documented during the return process to maintain traceability.

Once the batch is identified, the returned item should be inspected to determine if it meets quality standards for resale. If the item is acceptable, it can be returned to inventory with proper documentation of its batch information.

If the item is damaged or otherwise unsellable, it should be properly disposed of according to your company’s protocols. Be sure to document the disposal, including the batch number and reason for disposal, to maintain accurate records and comply with any relevant regulations.

Does ShipBob support batch tracking?

Yes, ShipBob offers lot management capabilities that provide comprehensive support for batch tracking. When you send inventory to ShipBob, you can create WROs that include specific batch or lot numbers for your products. This ensures that your inventory is properly labeled and tracked from the moment it arrives at a ShipBob fulfillment center.

ShipBob’s system also supports first-in, first-out (FIFO) and first-expired, first-out (FEFO) fulfillment logic, ensuring that older batches are shipped out before newer ones to minimize waste from expiration.

In the event of a recall, ShipBob’s team can quickly identify affected batches and take appropriate action, whether that means isolating inventory, handling customer returns, or coordinating disposal.

What’s the most cost-effective way to start batch tracking for a small business?

For small businesses just starting out with batch tracking, a simple spreadsheet-based system can be a cost-effective solution. The key is to establish clear standard operating procedures (SOPs) for documenting batch information, monitoring expiration dates, and tracking inventory movements.

As your business grows, you may want to invest in affordable scanning apps that work with smartphones or tablets. These tools can help you quickly and accurately capture batch information without the need for expensive hardware.

There are also many inventory management software options that offer tiered plans. These solutions can provide a more robust framework for batch tracking without breaking the bank.