Verified & Reviewed

Published on October 8, 2025 Written By Kristina Lopienski

Published on October 8, 2025 Written By Kristina Lopienski

Subscribe for More

This blog posts includes an excerpt from “Unboxing Your Future: Successful Retail in a Post-COVID Era,” a report written by Rick Watson of RMW Commerce, commissioned by ShipBob.

Foreword by ShipBob

While brands desire growth, it usually doesn’t come without some headaches. These growing pains can be felt on the supply chain side, including outgrowing your current fulfillment setup.

No one looks forward to the work that is required to switch fulfillment providers, move into a new warehouse space, or transition from outsourced to in- house (or potentially vice versa) – but many brands may never have been that happy with their previous solution to begin with, whether that’s a mom-and-pop provider, a 4PL, or multiple systems that are Frankensteined together.

Some brands are left wondering: Why isn’t there a solution that combines the best parts of both a 3PL and self-fulfillment, without the downsides?

Enter the “Fulfillment Accelerator” – a term coined by Rick Watson that refers to a new category of fulfillment solutions that offer scale, expertise, flexibility in technology adoption and facility ownership, and global, omnichannel, and customization capabilities, allowing growing brands to choose their own path.

Here at ShipBob, we provide all of that and more, and seek to be the last fulfillment partner you’ll need with solutions including:

- Outsourced fulfillment capabilities

- A warehouse network across the US, Canada, mainland Europe, the UK, and Australia

- DTC and B2B fulfillment

- Kitting and customization

- Support services

- A real-time fulfillment platform that features data-driven analytics

- A standalone WMS that can be used in brands’ warehouses

The following five chapters are an excerpt from the report, “Unboxing Your Future: Successful Retail in a Post-COVID Era,” written by Rick Watson of RMW Commerce, commissioned by ShipBob.

Executive Summary by RMW Commerce

Supply chain is presented as one of the critical enablers for the growth of a brand. While most brands are looking for solutions to these problems, they are often disappointed by the solutions they find. This report reviews these potential solutions and reveals the reasons they fall short.

Next, the report builds a case for a new category of logistics provider combining people, process, and technology into a unified, flexible, and integrated solution called the Fulfillment Accelerator. The requirements and benefits of this category of provider are explained.

Evaluating and adopting solutions in the Fulfillment Accelerator category is considered in depth. The report provides realistic evaluation criteria that a brand can use to overcome their most common concerns when making a solution decision of this magnitude.

In summary, RMW Commerce posits that the Fulfillment Accelerator is exactly the right type of solution for a brand entering the middle-market in order to power the next generation of their growth. Brands should be able use this type of solution until approximately 100,000 parcels per month, and possibly beyond.

The future of supply chain solutions is indeed bright with the next generation of Fulfillment Accelerator solutions coming online with a proven track record. RMW Commerce hopes to illuminate this new category and its benefits for brands in this comprehensive report.

Business Imperative

Scaling a direct-to-consumer brand has always been difficult. Brands must choose the right audience, attract them, and deliver an outstanding product, service, and experience to customers – all with a healthy profit margin.

The new imperative is to achieve a great customer experience through packaging and delivery, wherever the consumer shops, on time and in full, and at a profitable price point, wherever the consumer orders from.

The most important tenets of this operating model are as follows:

- Accurate inventory and date-definite delivery: Operational excellence creates accuracy: people, processes, and technology work together. That said, accurate inventory alone is insufficient. Precise delivery promise dates are needed to increase buyer trust further.

- Differentiated omnichannel experiences: Brands increasingly need to “wow” consumers, regardless of whether they are on websites, marketplaces, or in retail stores. Retail is no longer an optional component of a vertically integrated brand’s strategy.

- Substantial reduction in supply chain expenses: Brands require a path for supply chain costs to level off, and eventually drop, as the company scales. Focusing on profitability has been a critical missing element in DTC ecommerce’s history. Growing brands need leverage in their supply chain.

What’s So Hard About Supply Chain?

For many DTC brands, costs keep rising, right along with consumer expectations. Some of the top supply chain challenges growing brands face are as follows:

- Inventory accuracy: Accurate inventory allows an organization to determine how much inventory is available to promise. Inaccurate inventory can have effects across a company including marketing, finances, and customer experience.

- Scaling and workforce issues: Workforce is what keeps a supply chain executive up at night. FreightWaves reports that labor shortages and workforce issues are the top concerns of supply chain managers. Industry statistics show that the average warehouse worker’s salary is up by 38% over the past 5 years. Compounding these wage increases has been a shortage of available workers. A recent Ivanti Wavelink survey found that among more than 208 supply chain professionals, 57% reported worker shortages as their greatest challenge – the highest answer.

“The Inefficiency of the pick and pack process was at the top of our list for us. Without a WMS, we had to keep everything alphabetized in the warehouse, which was unmanageable at our scale. We could not double our capacity easily. At our growth rates, that is an existential threat to the business.”

– Ben Tietje, VP Operations, Earthley

- Access to discounted shipping rates: Carrier costs are passed to shippers through an annual General Rate Increase (GRI). While these rate increases in the past few years have hovered in the range of 7%, with the addition of other surcharges, the annual rate increases felt by shippers are sometimes in the low double-digits of 10% or more. Growing brands don’t have the buying power of larger brands and retailers nor do they have the sophistication, data, and tools to negotiate with larger shipping carriers like UPS and FedEx.

- Support for additional channels: Once growing brands move from DTC into marketplaces and retail channels, they face new marketing challenges: How do we position ourselves for success in these new outlets? The challenges don’t stop with marketing, however. Many merchants’ operations are not sophisticated enough to support these new channels. Often, it’s not even the shipping requirements themselves – it’s about technology and connectivity. Marketplaces tend to prefer API-based communication. Retailers tend to prefer EDI-based connectivity. Each of these new shipping and technology requirements means more complexity for a brand’s IT and supply chain teams.

- Customization and unboxing: From a consumer perspective, everything that happens from the time a customer receives the box to the time they start using the product is part of the unboxing experience. From a supply chain perspective, all the materials involved in unboxing become new supply chain requirements. When a business’s founders are in the warehouse, they can pack each box with special care. As a brand’s volume grows to thousands per month, this level of care is not generally possible without specialized systems.

Searching for Solutions

Fast-growing brands have achieved incredible success, reaching thousands of monthly shipments, only to be rewarded with greater complexity, rising costs, and increasing customer demands. Once a brand figures out how to scale its customer acquisition to the next level, scaling operations is next.

This table outlines the types of questions brands ask about scaling operations.

| Problem | People | Process | Technology & Provider |

| Inventory Accuracy | How easy is it to train staff on the new systems? | Can a new picking process support both growth and accuracy at the same time? | How does management get a single view of inventory? Can software reinforce the new quality processes? |

| Scaling & Workforce Issues | Where is accessible knowledge and talent to help scale the business? | Is there a way to own the facility while leveraging outside expertise? | Does the business’s software support all the channels that are required for growth? |

| Access to Discounted Shipping Rates | Do the sales rep understand my needs? | Does the business have the software required for proper rate shopping? | Can the volume discounts of a larger provider be leveraged as a mid-sized brand? |

| Support for Additional Channels | Does staff have the expertise to support the channel’s requirements? | What are the penalties for missing a channel’s packaging and timing requirements? | Does the business have the technology systems and partners needed to support transactions? |

| Customization & Unboxing | Is it easy for employees to step on the line without making mistakes? | How does the boxing process support consistency of experience delivery? | Does software support the customization the products need? |

Brands lack expertise to reach the next growth stage but cannot afford to sit still. The most common solutions brands try to adopt during their journey include:

Potential Solution: Hiring More Pickers

The current situation: One of the first things a growing brand does to keep up with order volume is to hire more pickers. After all, it’s expensive to install new software or build a new facility. If new staff can keep up with the volume using existing processes, why not try this first?

Why it’s not enough: At this point in their development, many brands use solutions like Shopify to manage their ecommerce inventory, and ShipStation (along with plugins) to manage their picking and label generation. While Shopify is great for inventory management for an ecommerce website, many brands have not configured it to handle their retail SKUs. Furthermore, without new hardware and software, these extra pickers are still manually verifying orders, which is insufficient for growing brands shipping tens of thousands of orders daily.

Potential Solution: Using a Local “Mom & Pop” Logistics Provider

The current situation: To help solve a problem with labor, the first thought by many brands is to outsource to a professional local provider. While this solves the immediate problem and allows a brand to unlock the next level of growth, at some point, the solution outlives its usefulness.

“We were using a local 3PL which ultimately did not fit a DTC growth brand. We wanted to get away from them because they were screwing up orders, sometimes causing weeks of backlogs! Our promotions and viral events were the cause: whenever they got too many orders, we would inevitably see more delays.”

– Leo Walter, COO, Bloom Nutrition

Why it’s not enough: Over time, the advantages of a local provider start to be outweighed by the disadvantages. There are a few reasons that brands outgrow such solutions:

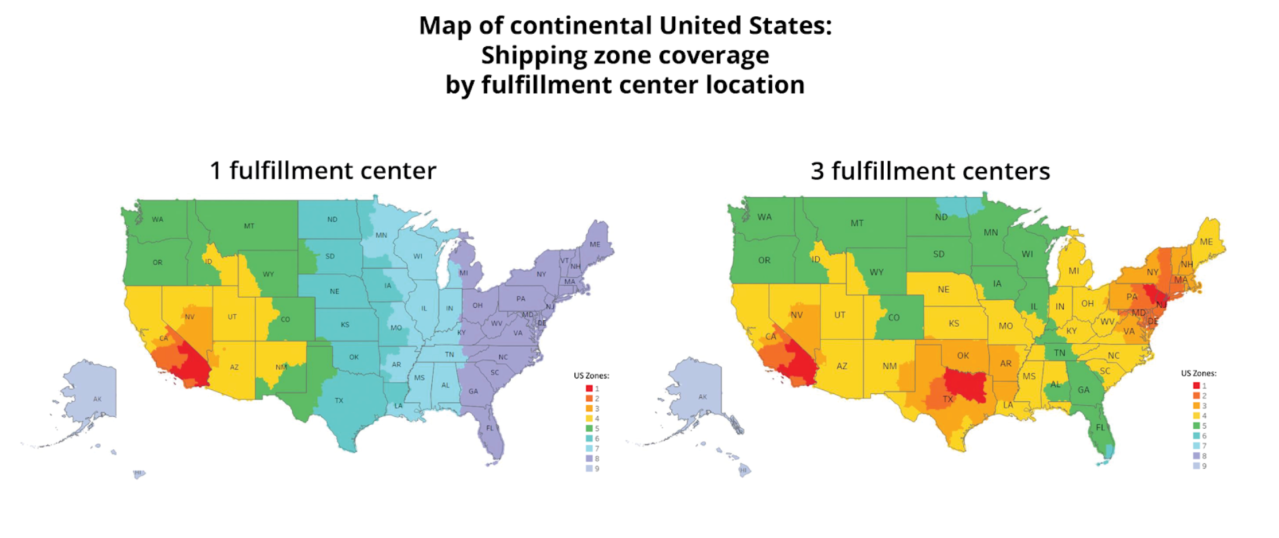

- Footprint: Growing brands have customers in all areas of the country, not just the closest zones to the local 3PL.

- Scale: Once a business is the largest customer at that local 3PL, the facility can become backlogged with both inbound items and outbound parcels, sometimes for weeks.

- Access to rates: Local 3PLs often lack the scale to pass along significant rate discounts.

- Digital channel expertise not available: Many brands are surprised to learn that while local 3PLs have been around for a long time, many primarily cater to retail-oriented brands – not ones that deliver directly to consumers.

Source: ShipBob, US Shipping Zones

Potential Solution: Outsourcing to a Global 3PL

The current situation: To solve some of its ongoing issues, a brand often seeks out a global provider. The decision to work with a global expert decision has the following benefits:

- Scale: Larger providers have been working with large enterprise brands for years and, as a result, can handle sustained fulfillment throughput without issues, including sudden peaks in demand caused by flash sales, viral videos, etc.

- Access to rates: As a small to medium-sized customer at a more prominent provider, a growing brand can leverage the combined shipping power of the entire 3PL network.

- Capabilities: Growing brands need to provide a great experience to their customers wherever they shop: Amazon, retail, DTC, or internationally. Global 3PLs often have decades of experience providing these capabilities to larger brands.

Why it’s not enough: While a global 3PL often achieves several of the brand’s needs, new challenges are often introduced:

- Integration: There is often no systematic way to connect to a 3PL without a significant EDI engagement or custom integration. The impact on a brand is a months-long integration project, rather than one taking just a few days.

- Lack of customization: To capture customers who continue to shop with household name brands, challenger brands must provide better experiences. This is difficult for a scaled 3PL facility because each new customization cuts into the provider’s margin.

- Lack of a unified view: If a growing brand decides to use a global provider for some products, but not all, then data unification becomes a new challenge. A brand’s operations can become fragmented, which makes it more difficult to spot challenges promptly.

Potential Solution: Installing an Enterprise Warehouse Management System

The current situation: Brands working in their own facilities often exceed what inventory spreadsheets and ShipStation can offer. In response to this challenge, operators are often told to install a “real” Warehouse Management System (WMS). WMS can provide much-needed reliability, structure, customizability, and scale to a growing brand’s operations.

Why it’s not enough: While the benefits of a proper WMS are well-known — the challenge is not in the outcome, it is in the journey. On the road to an enterprise-grade WMS, many brands run into the following challenges:

- Cost: A proper WMS can be an up-front commitment of several hundred thousand dollars, plus a similar commitment to a trusted professional services provider to implement it properly.

- Implementation time: Gone are the days of 90 days to pilot a software solution, learn from the pilot, and then spend 12-15 months on a phased implementation project. In 15 months, the world will have changed, along with the brand’s needs.

- Training and processes: Even after a complex implementation is done, improvement is difficult and takes persistence. Without extraordinary processes and management, brands may not realize the expected results from the implemented software.

- High risk of failure: They say the road to hell is paved with good intentions. In Information Technology, however, the road to hell is paved by something else: major system implementations. Ernst & Young reports that as many as 70% of supply chain technology implementations fail.

Potential Solution: Building a New Facility

The current situation: Space constraints in a brand’s current facility can keep a logistics leader up at night. Once a warehouse reaches its capacity, it is natural for a CFO to attempt to capitalize its infrastructure in an attempt to reduce per-parcel operational expenses.

Why it’s not enough: According to BuildingsGuide, even a relatively small 10,000 sq. ft. facility can cost up to $250,000. Of course, such a small facility will not support the needs of a growing brand. For that, a larger 50,000+ sq. ft. facility will cost well over a million dollars to build. These up-front capital requirements put this option out of reach of most brands.

In Search of an Integrated Fulfillment and Software Solution

In logistics, there is always a balance between several considerations:

- Capital expenses

- Footprint

- Customization

- Volume

- Channel capability needs

Outsourcing fulfillment falls short because flexibility often suffers with scale. Managing everything in-house is also complex due to the issues implementing a Warehouse Management System.

This table summarizes the issues and proposes an ideal solution alternative:

| Element | Capital Expense | Footprint | Customization Capability | Volume Capability | Channel Reach |

| Owned Facility | High | Local | High | High | Omnichannel |

| Local 3PL | Low | Regional | Medium | Low | Low |

| DTC 3PL | Low | National | Low | High | 1-2 |

| Global 3PL | Medium | Global | Low | High | High |

| Enterprise WMS | High | Global | High | High | High |

| Ideal Solution | Low | Global | High | High | Omnichannel |

Fulfillment Needs

From a fulfillment point of view, an ideal solution would combine the good parts of 3PL without the limitations. In other words, scale without sacrificing the ability to customize the product packaging and unboxing experience.

| Customization / Scale | Few Products with No or Similar Customizations | Dozens of Products with Different Customization Needs |

| Low volume (< 10,000 orders) | In-house | Local 3PL provider |

| High volume (> 10,000 orders) | Global 3PL provider | Ideal solution needed |

Technology Needs

From a software point of view, the effective solution has the scale of enterprise software but without the up-front capital and implementation costs.

| Capital Expenses / Scale | Lower Capital Expenses | Higher Capital Expenses |

| Low volume (< 10,000 orders) Software / Hardware | Software: Shopify + ShipStation Hardware: None | N/A |

| High volume (> 10,000 orders) Scanning & automation needs | Ideal solution needed | Software: Enterprise WMS Hardware: Conveyors & robotics |

The following section proposes an entirely new market sector that represents a way through these challenges: combining the scale, expertise, and channel capabilities, with low capital requirements.

The Fulfillment Accelerator: A Way Forward

A fast-growing brand that has reached this stage must answer this simple question:

How can the brand move as quickly as possible from sustained early scaling to an established brand?

Unboxing the Fulfillment Accelerator

This report has established that a fast-growing brand needs supply chain excellence to continue its growth trajectory. The worst-case scenario for a brand like this is for more demand than can be fulfilled profitably, causing a plateau in growth.

Unfortunately, current market solutions fall short of preventing this growth plateau. There are solutions for new brands pre-product-market-fit, and there are solutions for established brands with a large amount of capital. In between pre-product-market-fit and established brands, there is a clear gap in available market solutions. To fill this gap, RMW Commerce proposes a new category of fulfillment partner called the Fulfillment Accelerator.

Having eliminated most other alternatives for a growing brand, this category of fulfillment solution has the following broad characteristics:

- Solid capabilities: A combination of software, facilities, workforce, and expertise that can be adopted flexibly in a way the brand sees fit are needed.

- Hard-won expertise: These capabilities must be provided by a real operator, not just a software provider re-selling logistics solutions.

These characteristics ensure that brands not only have the right capabilities but also that they adopt these capabilities quickly and at the right phase in their development.

Requirements of Fulfillment Accelerator Solutions

Solutions in the Fulfillment Accelerator category are designed to offer a new frontier of service for these brands, in an affordable way.

| Requirement | Description |

| Inventory Management | While solutions like ShipStation, Shopify, and spreadsheets can work for SMBs, a mid-market brand needs unified inventory visibility across channels. Technology and improved processes work together to deliver the desired solution: near-perfect inventory accuracy and visibility. |

| Access to Low Rates | Growing brands are not established enough to get the industry’s best rates, but can “punch above their weight” by using the rates from a larger partner. |

| Low Capital Requirements | Brands cannot afford to spend 6+ figures and 9+ months implementing enterprise supply chain software. Instead, the barrier to adoption must be low and funded by operating expenses. |

| High Throughput | Scale in inbound and outbound processing is table-stakes for a growing brand. The solution must handle sustained throughput and sudden bursts created by viral videos, and promotional events. |

| Date-Definite Delivery | An outstanding experience requires the ability of a brand to make consistent promises they can deliver. This critical marketing benefit can only be achieved if a brand can promise an accurate delivery date up-front, and then consistently deliver on it. |

| Omnichannel Capabilities | Growing, modern brands require support for DTC, store replenishment, marketplace preparation, and retail dropship capabilities. |

| Customization at Scale | Ability to support custom packaging, marketing inserts, tissue paper, and custom rules by product segment. If a brand’s unboxing experience is not unique, it will struggle to differentiate in a crowded market. |

| Global By Default | Top brands have the technology to market to the world’s buyers. As traction builds in new geographies, a provider with a warehouse presence in essential markets is critical for a brand to capitalize on these opportunities. |

Benefits of Fulfillment Accelerator Solutions

As a category, solutions in the Fulfillment Accelerator category have the following major advantages over other solutions.

| Benefit | Description |

| Operating Leverage | Growing brands need to ensure that EBITA can grow faster than revenue. This can only be done if parcel volume does not require a similar growth in warehouse headcount. |

| Customer Loyalty | Long-term customer loyalty involves keeping promises. A delivery promise, backed by branded, customizable packaging, delivers the fantastic post-purchase experience that all brands seek. |

| Faster Time-to-Market | Time is of the essence for a growing brand. Cloud-based solutions and concierge onboarding can help onboard a brand in weeks rather than months — significantly improving speed to market and sidestepping competitive pressures. |

In addition to these benefits, solutions in the Fulfillment Accelerator category reduce the risk of implementation failure due to low up-front costs and shorter implementation times of cloud-based technologies. Companies in the Fulfillment Accelerator category must provide detailed onboarding guidance to ensure a successful launch.

In some ways, a Fulfillment Accelerator partner can become the de facto Chief Supply Chain Officer — a role that a brand may not be able to afford at this stage of growth.

Fulfillment Accelerators Meet Growing Brands Where They Are

While this report presents a brand’s journey as linear, in practice, it is not. Experience and research finds that at least 70% of fast-growing brands are fulfilling from an existing leased facility with their labor, while the remaining have fully outsourced fulfillment to local or global third-party logistics providers.

Providers in the Fulfillment Accelerator category can be a good match for companies in this situation:

- Software and process expertise can be applied to a brand’s existing facility and labor investments, without adopting other solution elements.

- Improved shipping rate cards can immediately improve a brand’s unit economics.

- New facilities can be brought to bear to reduce cost and delivery time in existing markets.

- New channels and capabilities can be unlocked within existing facilities, or using outsourced facilities.

- International markets can be unlocked without disrupting the operation of existing facilities.

The key differentiator of a Fulfillment Accelerator solution is its flexibility in technology adoption and facility ownership: growing brands can choose their own path.

Evaluation and Adoption Concerns

Evaluation Criteria

As a new space, many brands may not be familiar with evaluating Fulfillment Accelerator solutions. This section aims to guide brands evaluating and adopting new entrants to the space. These requirements are as follows:

| Requirement | Description |

| Inventory Accuracy | A mid-market brand needs unified inventory visibility across channels. This requires both process and technology improvements. |

| Access to Low Rates | A mid-market but growing brand should be able to save on their current “rack rates.” |

| Easy to Adopt | Large capex requirements are a non-starter. Implementation time and cost barriers to adoption must be low. |

| Omnichannel Capabilities | Growing, modern brands require support for DTC, store replenishment, marketplace preparation, and retail dropship capabilities. |

| Customization at Scale | The ability to support custom packaging, marketing inserts, tissue paper, and custom rules by product segment is required. |

| Dedicated Support and Account Management | Is a named contact reachable at any time? Does the provider have personnel on-site in each facility? |

| Supports Both In-Sourced and Outsourced Solutions | Brands need the flexibility to use the same set of software and processes regardless of whether they are being used in a brand’s own facility or those of an outsourced provider. |

An operator mentality is also important. While there are many logistics providers in the market, many of them are so-called technology-only 4PLs. This means that the vast majority of these players have no real-world logistics experience: instead, they are software developers. Any software they provide could be rejected by real operators if they are not simultaneously “eating their own dog food.”

“During our evaluation, ShipBob stood out to us because it was the only company using its own software in its own facilities. This is one of the company’s core differentiators.” – Ben Tietje, VP Operations, Earthley

Adoption Concerns

The goal of this section is to dispel common misconceptions and offer considerations to potential buyers to help a brand owner become comfortable with any risks or tradeoffs.

How Can I Trust Another Provider?

Most merchants have been burned by one or more providers and worry about giving too much control to a third-party.

| Concern | Questions to Address the Concern | Impact |

| Burned By a 3PL Before | Does the provider allow the brand’s owned facility in addition to outsourcing? Is there a dedicated account manager? What is the returns process? How many facilities does the provider own and operate? | Top providers can provide a thorough onboarding and service plan, in addition to solid category-specific references. |

| Worried About Lack of Control | How are non-owned facilities managed? Can the software be used in the brand’s own facility? Can the software integrate with the brand’s existing in-house software? | Real-time visibility and proper client service is the antidote to the lack of control. The provider’s software should integrate seamlessly with a brand’s existing technology assets. |

How Quickly Can I Achieve the Promised Results?

Speed to market is critical to the success of mid-market brands. Even if a solution provides solid capabilities, ease of adoption is often the deciding factor for the success of a long-term relationship.

| Questions to Address the Concern | Impact |

| How long will the provider be at the brand’s facility during launch? What is the full picture of all expenses incurred during onboarding? How quickly have customers in similar situations onboarded? What issues are likely during onboarding? | The best providers can ensure that the solution is affordable for a brand not spending hundreds of thousands of dollars up-front for a new solution. |

Will I Outgrow the Solution?

The final part of an evaluation is calculating how long a potential solution will be viable for the business. Onboarding to any solution usually takes weeks or months, depending on the solution. If a brand’s business outgrows the solution too soon, the promised results may never be achieved.

| Concern | Questions to Address the Concern | Impact |

| Flexibility | Will the solution integrate with existing technology solutions? How difficult is the integration process? Can the brand continue to operate in its own facilities? When do enterprise clients stop working with the provider and move everything in-house? | Asking difficult questions to a provider in advance of the relationship helps understand the risks involved in a major decision. |

| Client Retention | Can the provider offer several references in the same category that have been with the solution for more than two years? Can the provider explain specifically how the brand’s intake, pick/pack, and shipping processes will change after adopting the solution? How will the provider help train the brand’s staff? | Brands that learn from other clients on the platform can predict their own experiences of being a customer of the solution as well. |

The Future of the Fulfillment Accelerator Category

The future roadmap of the Fulfillment Accelerator category will fall into the following themes:

- Ability to support new markets and channels

- Ability to support new and different types of specialized products

- Ability to support increased automation

The more capabilities that are provided by Fulfillment Accelerators, the faster brands will be able to scale due to the benefits delivered.

The future is bright for growing brands with the right supply chain partner. Coming out of a hyper-growth COVID period, the capital available to brands has declined. This has forced many brands to shelve their hyper-growth plans and, instead, increase their concern for EBITDA. At the same time, the channel, operational, and market capabilities that brands need to survive have never been greater.

Growing brands have reached a breaking point and are searching for solutions.

Unfortunately, the tools available to brands in the past are not the ones that will power the next wave of growth. Building the brand’s own facility, outsourcing entirely to a 3PL, and implementing an enterprise Warehouse Management System are all fraught with peril. These solutions come with high capital costs, lack of control, and diminished visibility.

Fortunately, another category of supply chain solution exists in today’s market: the Fulfillment Accelerator. Solutions in this category offer medium-term scalability options, combining high-throughput, low-capital requirements, and impressive customizability. Most importantly, this category’s solution is immediately accretive to the brand’s bottom line because of attractive shipping rate cards and access to new markets. As the Fulfillment Accelerator category grows over time, it will become more viable as a solution not only for mid-market brands, but also complex enterprise operators, too.

This report has been written by RMW Commerce, commissioned by ShipBob. We thank Rick Watson for his report.

How ShipBob Fills the Gap in the Market

As a consultant in the industry who has a deep understanding of mid-market brands’ needs, we agree with Rick Watson’s perspective.

We’re so bullish on it in fact, that ShipBob offers the Fulfillment Accelerator solution and more.

No matter how you fulfill orders, your business can leverage ShipBob’s solutions to achieve more accurate, efficient, and affordable fulfillment – no matter whether you’re using a fully outsourced model, a warehouse management system (WMS) for in-house fulfillment, or a hybrid approach.

- Outsource fulfillment: If you’re looking to take a hands-off approach to fulfillment, ShipBob can store your inventory and pick, pack, and ship orders for you from any of our fulfillment centers in the US, Canada, the UK, mainland Europe, and Australia.

- Keep fulfillment in-house with ShipBob WMS: If you have your own warehouse, you can implement the ShipBob WMS to power your entire global fulfillment network.

- Turn to a hybrid fulfillment model: Have a warehouse but want to optimize costs for your best-sellers, unlock additional scale, or cater to a region you’re not located near? Use ShipBob’s WMS in your warehouse(s), and leverage any of ShipBob’s fulfillment centers in other regions or countries to reduce transit times and shipping costs.

| Features and capabilities you unlock | Outsourced fulfillment to ShipBob | ShipBob WMS |

| Turnkey integrations with all major ecommerce platforms | X | X |

| API & dozens of integrations in the ShipBob App Store (e.g., NetSuite, Klaviyo, & Gorgias) | X | X |

| The ShipBob dashboard (real-time inventory, order, shipment, and returns management software) | X | X |

| Standalone WMS for your own warehouse (advance features like cluster picking, batch picking, and pick to cart, etc.) | X | |

| ShipBob’s global fulfillment center network (US, Canada, UK, EU, & Australia) | X | X |

| DDP & DDU international shipping from any location | X | X |

| Advance analytics and reporting tools | X | X |

| Omnichannel & marketplace integrations (e.g., Amazon FBM, Amazon FBA prep) | X | X |

| B2B & EDI capabilities for both retail distribution & dropshipping | X | X |

| Customization & branded unboxing capabilities | X | X |

| White-glove onboarding & support | X | X |

| A dedicated Merchant Success Manager and an Executive Sponsor | X | X |

Want to learn more?

Download Rick’s full report here, or click the links below to explore each of ShipBob’s solutions to discover which is right for your business.

Outsource Fulfillment to ShipBob or Get ShipBob WMS for My Warehouse