Verified & Reviewed

Last updated on October 7, 2025 Written By Rachel Hand

Last updated on October 7, 2025 Written By Rachel Hand

Subscribe for More

Maintaining an accurate inventory count is essential for any growing ecommerce brand – but as operations scale, so does the complexity of tracking stock across multiple SKUs and locations.

That’s where a wall-to-wall inventory count comes in.

Also known as a full physical inventory count, wall-to-wall inventory provides a complete snapshot of your stock at a specific moment, helping you reconcile discrepancies, prepare for audits, and improve data accuracy.

On the other hand, it can also be resource-intensive, and often disruptive – unless you have the right tools and strategy.

In this guide, we’ll break down what wall-to-wall inventory means, when to use it, and how to streamline the process with modern technology and the right fulfillment partner.

What is wall-to-wall inventory?

Wall-to-wall inventory, also known as a full physical inventory or a complete stock take, refers to the comprehensive process of counting and verifying every single item in a warehouse, storage facility, or retail store.

This thorough approach to inventory counting provides a complete and accurate “snapshot” of your entire inventory at a specific point in time, and helps you make sure your records reflect the actual stock levels on hand.

Unlike other inventory counting methods that focus on specific subsets of products on a rotating basis (like inventory cycle counting), a wall-to-wall count covers every SKU in your facility without exception. This complete coverage is what sets wall-to-wall inventory apart, making it an essential tool for reconciling data discrepancies, identifying stock issues, and ensuring the overall accuracy of your inventory records.

When and why do businesses conduct wall-to-wall inventory counts?

There are several scenarios that typically trigger the need for a comprehensive wall-to-wall inventory count. Some of the most common reasons include:

- Annual audits: Many businesses, particularly those in the retail sector, conduct full inventory counts at the end of their fiscal year to ensure accurate financial reporting and valuation of their stock.

- System migrations or implementations: When transitioning to a new inventory management system or ERP platform, a wall-to-wall count helps verify data accuracy and identify any discrepancies between the physical stock and digital records.

- Suspected inventory issues: If a company suspects significant stock discrepancies, theft, or other inventory-related problems, a complete count can help pinpoint the source of the issue and provide a fresh baseline for moving forward.

In addition to these specific triggers, many seasonal businesses strategically schedule their wall-to-wall counts during slower periods to minimize disruption to normal operations. This approach allows them to reconcile their inventory data before entering peak seasons, ensuring they have an accurate picture of their stock levels when it matters most.

For ecommerce businesses that utilize multiple fulfillment centers or warehouses, coordinating simultaneous wall-to-wall counts across all locations provides a network-wide inventory count at a single point in time. This synchronization is crucial for maintaining accurate stock records and making informed decisions about product allocation, reordering, and distribution.

6 wall-to-wall inventory count best practices

Conducting a successful wall-to-wall inventory count requires careful planning and execution. By following these best practices, you can ensure an efficient and accurate count while minimizing disruption to your regular operations.

1. Evaluate labor and time requirements

Before beginning your count, it’s essential to estimate the labor and time needed to complete the process.

A good rule of thumb is to allocate one counter for every 500-1000 SKUs, depending on the size and complexity of your inventory. For example, if you have 5,000 SKUs, you may need a team of 5-10 counters.

It’s also important to consider the size and layout of your storage area when estimating time requirements. Counting small, easily accessible items will generally be faster than counting bulky or hard-to-reach products.

To streamline the process, consider breaking your count into manageable sections or zones. This approach allows you to assign specific areas to each counting team, reducing the risk of duplicated efforts or missed items.

2. Organize and label all SKUs properly

A well-organized inventory is crucial for an accurate count. Before beginning, make sure you:

- Ensure that all products are properly labeled and stored in their designated locations (this may involve temporary location mapping or zone designation in your warehouse setup to help counters navigate the area efficiently).

- Pay special attention to similar-looking products, as these can easily be miscounted. Consider using color-coded labels or separate storage areas to differentiate between items with similar packaging or appearance.

- Conduct a pre-count clean-up, straightening shelves and removing any debris or clutter that could hinder the counting process.

- Create a clear map or diagram of the counting area with labeled sections can further streamline the process and reduce the risk of errors.

3. Train teams and verify data entry

Proper training is essential for ensuring that your counting teams are equipped to perform their tasks accurately and efficiently. Develop a comprehensive training program that covers the entire counting process, from identifying and recording SKUs to handling discrepancies and verifying data entry.

Provide hands-on practice sessions to familiarize counters with the tools and techniques they’ll be using, such as barcode scanners or manual counting procedures. Create clear documentation and quick-reference guides that team members can refer to during the count.

To minimize errors, consider implementing a two-person counting system, where one team member counts the items while the other verifies the count and records the data. This approach helps catch mistakes in real-time and ensures a higher level of accuracy.

4. Plan for discrepancies and post-count reconciliation

No matter how carefully you plan and execute your count, discrepancies are almost inevitable. Establish a systematic approach for investigating and resolving variances, with clear guidelines for acceptable thresholds based on product value or other factors.

Assign specific team members to investigate discrepancies, and create a standardized reconciliation workflow. This might involve recounting specific items, checking for misplaced inventory, or comparing data entry records.

Be sure to document all discrepancies and their resolutions for future reference and auditing purposes. This information can be valuable for identifying patterns or areas for improvement in your inventory management processes.

5. Maintain some operational continuity

While a wall-to-wall count is a significant undertaking, it doesn’t have to mean a complete shutdown of your business. With careful planning, you can maintain essential operations while still conducting a thorough count.

Consider strategies like staggering counts across different sections or facilities, or scheduling the count during slower business periods. Prioritize counting areas that have the least impact on customer orders or production schedules.

If you anticipate any delays or disruptions, be sure to communicate proactively with your customers and stakeholders. Develop communication templates that explain the reason for the count and provide realistic timelines for any affected orders.

You may also need to temporarily modify your picking paths or fulfillment workflows during the count. Work with your operations team to develop a plan that minimizes disruption while still allowing the count to proceed efficiently.

6. Streamline your wall-to-wall counts with technology

While the basic principles of wall-to-wall inventory counting remain constant, modern technology has revolutionized the process. Implementing the right tools and systems can dramatically reduce counting time and improve accuracy, ultimately saving your business time and money.

Recommended barcode scanners and mobile devices

Investing in high-quality barcode scanners and mobile devices is one of the most effective ways to streamline your counting process. Look for devices with features like long battery life, durable construction, and fast scanning speeds.

Mobile scanning devices offer greater flexibility and efficiency than fixed terminals, allowing counters to move freely through the warehouse. Consider accessories like wearable scanners or voice-picking systems to further optimize the process.

Warehouse management software features

A robust warehouse management system (WMS) is essential for efficient inventory counting. Look for features like real-time data synchronization, customizable counting workflows, and integration with your existing ERP or accounting systems.

ShipBob’s WMS, for example, offers a range of tools to streamline inventory management, including real-time inventory tracking, automated reorder points, and advanced reporting capabilities. By centralizing your inventory data in a single, cloud-based platform, you can ensure accuracy and consistency across all your counting processes.

“Integrating ShipBob’s WMS into our Miami warehouse has really helped our in-house business on so many levels. It did wonders for our inventory accuracy—having a system that would decrement inventory in real-time based on shipments gave us a lot more insight into our inventory movement and made our inventory counts in different fulfillment stages much more reliable.

Before ShipBob, we used to do a lot of that tracking and updating manually and it was a lot more work for our team as well, so automating everything through ShipBob’s WMS has been very helpful. Also with the amount of sales volume that we drive, we have to nail our inventory tracking across the entire supply chain.”

Rachel Tannenholz, President, and Melissa Mosheim, Director of Logistics at Aroma360

Integrations with ERP platforms

Seamless integration between your counting tools and ERP platform is crucial for maintaining accurate inventory records. Look for solutions that offer real-time data synchronization and robust API connections.

Many modern inventory management systems offer pre-built integrations with popular ERP platforms like NetSuite, SAP, or Microsoft Dynamics. These integrations allow for automatic data transfer and reconciliation, reducing the risk of manual errors and ensuring a single source of truth for your inventory data.

Real-time data synchronization and analytics

One of the most significant advantages of modern inventory counting technology is the ability to access and analyze data in real-time. Cloud-based systems enable instant updates and verification, allowing you to identify and resolve discrepancies as they occur.

Real-time analytics can also provide valuable insights into your counting process, such as identifying bottlenecks or areas for improvement. Dashboards and reporting tools can help you monitor progress across multiple locations and teams, ensuring a consistent and efficient count.

Before beginning your count, be sure to thoroughly test your equipment and connectivity to avoid any technical issues. It’s also a good idea to invest in backup systems or contingency plans in case of unexpected technology failures.

Wall-to-wall inventory vs. cycle counting

| Wall-to-Wall Count | Cycle Count |

| A one-time process | An ongoing process |

| Provides a complete snapshot of your entire stock at one specific point in time | Counts portions of your inventory on a rotating schedule |

| Require significant resources | Less resource-intensive |

| Can be disruptive to regular operations | Minimally disruptive to regular operations |

| Comprehensive in scope | Partial in scope |

While a wall-to-wall inventory count provides a complete and accurate snapshot of your entire stock at a specific point in time, cycle counting is an ongoing process that counts portions of your inventory on a rotating schedule. Wall-to-wall counts require significant resources and can be disruptive to regular operations, but they offer the highest level of accuracy and comprehensiveness.

Cycle counting, on the other hand, is less resource-intensive and can be conducted without major disruptions to daily business. By counting a subset of your inventory on a regular basis, you can maintain a high level of accuracy between full counts and identify issues more quickly.

Many businesses use a hybrid approach, conducting an annual wall-to-wall count supplemented by regular cycle counts throughout the year. This combination provides the best of both worlds: a complete and accurate baseline from the full count, and ongoing accuracy maintenance from the cycle counts.

When to conduct a full count

There are certain scenarios where a wall-to-wall count is necessary to restore confidence in your inventory data and ensure accuracy. These include:

- Major discrepancies between recorded and actual stock levels

- Implementation of a new inventory management system

- Annual financial audits or tax reporting requirements

- Preparation for peak sales periods or seasonal demand spikes

Conducting a full count before a high-volume period, such as the holiday season, can help ensure that your inventory records are accurate and up-to-date, reducing the risk of stockouts or overselling. Similarly, a wall-to-wall count after a system crash or major data issue can help restore confidence in your inventory data and provide a fresh baseline for moving forward.

When planning a full count, it’s important to schedule it during a lower-volume period to minimize disruption to your regular operations. This may involve conducting the count outside of normal business hours or breaking it into smaller sections to be completed over a longer period.

When cycle counting makes more sense

For businesses with stable operations and consistent inventory levels, cycle counting can be a more efficient and manageable approach to maintaining accuracy. By counting a portion of your inventory on a regular basis, you can spread the workload throughout the year and identify issues more quickly.

Cycle counting is particularly useful for businesses with large SKU counts, as counting every item in a single session may be impractical or impossible. By focusing on a subset of your inventory each cycle, you can ensure that every item is counted at least once within a specified timeframe.

Cycle counting can also be used to supplement wall-to-wall counts, helping to maintain accuracy between full counts. Identifying and correcting discrepancies on a regular basis helps you reduce the likelihood of major issues arising during your annual full count.

5 benefits of conducting a wall-to-wall count

While a wall-to-wall inventory count can be a significant undertaking, the benefits it provides extend far beyond simple stock verification.

Identifying shrinkage and discrepancies

One of the primary benefits of a wall-to-wall count is the ability to identify inventory shrinkage and discrepancies. When you compare your physical stock levels to your recorded inventory data, you can uncover issues such as theft, damage, or administrative errors.

When investigating discrepancies, it’s important to categorize them based on their root cause. This can help you identify patterns and develop targeted solutions to prevent future issues. For example, if you discover a high level of theft in a particular product category, you may need to implement additional security measures or adjust your storage practices.

Setting acceptable variance thresholds based on industry standards can help you prioritize your investigations and focus on the most significant discrepancies. Addressing these issues proactively lets you reduce the financial impact of inventory shrinkage and improve your overall profitability.

Boosting data accuracy and trust

Another key benefit of a wall-to-wall count is the improvement in overall data accuracy and trust as reconciling your physical inventory with your system records keeps your inventory data is reliable and up-to-date.

Accurate inventory data has far-reaching effects on your business, from improved sales forecasting and purchasing decisions to more reliable financial reporting. When your inventory records are trusted across departments, you can make informed decisions with confidence, reducing the risk of stockouts, overstocking, or other costly errors.

Accurate inventory data is also essential for financial valuation and reporting. If your inventory records reflect your actual stock levels, you can provide stakeholders with a clear and accurate picture of your business’s financial health.

Improving loss prevention

In addition to identifying existing shrinkage issues, a wall-to-wall count can also help you improve your overall loss prevention strategies. In thoroughly examining your inventory and storage practices during the counting process, you may uncover vulnerabilities or weaknesses in your security measures.

Based on your findings, you can then implement additional controls or adjust your procedures to reduce the risk of future losses. For example, you may need to install security cameras in high-risk areas, implement stricter access controls, or provide additional training for your staff on proper handling and storage techniques.

By conducting regular wall-to-wall counts and analyzing the results, you can continuously refine your loss prevention strategies and minimize the impact of inventory shrinkage on your bottom line.

Enhancing forecasting and demand planning

Accurate inventory data is essential for effective forecasting and demand planning. While it’s not the quickest approach, a wall-to-wall count makes sure that your baseline inventory levels are correct and provides a solid foundation for your sales projections and purchasing decisions.

Similarly, a wall-to-wall count can help you pinpoint slow-moving SKUs or excess inventory during a full count. With this information, you are equipped to make more informed decisions about your product assortment and lifecycle management (such as discontinuing or liquidating products that aren’t selling to free up valuable storage space).

Accurate inventory data also enables you to set appropriate reorder points and safety stock levels, reducing the risk of stockouts or overstocking. For seasonal businesses, conducting a wall-to-wall count before peak periods can help ensure that you have the right products in the right quantities to meet customer demand.

Restoring confidence after data issues

In the event of a major system failure or data corruption, a wall-to-wall inventory count restores confidence in your inventory records. Starting fresh with a complete and accurate count means you know your inventory data reflects your actual stock levels, giving you a reliable baseline (and peace of mind) moving forward.

This process can also help you identify any issues with your new inventory management system or processes. Your physical count should match your system records exactly; if it doesn’t, you have the opportunity to fix discrepancies or errors that may have occurred during the transition.

In addition to the practical benefits, conducting a full count after a major data issue can also provide a psychological boost for your team. It’s a good way to clean the slate and help your team “start fresh” with newly-verified inventory data that they know they can trust.

How ShipBob goes beyond “wall-to-wall” with continuous inventory accuracy

ShipBob’s technology-driven approach to inventory management offers ecommerce businesses a powerful alternative to traditional wall-to-wall counting. By providing real-time visibility and automated workflows across a global network of fulfillment centers, ShipBob enables brands to maintain a high level of inventory accuracy without the disruption and resource drain of a full physical count.

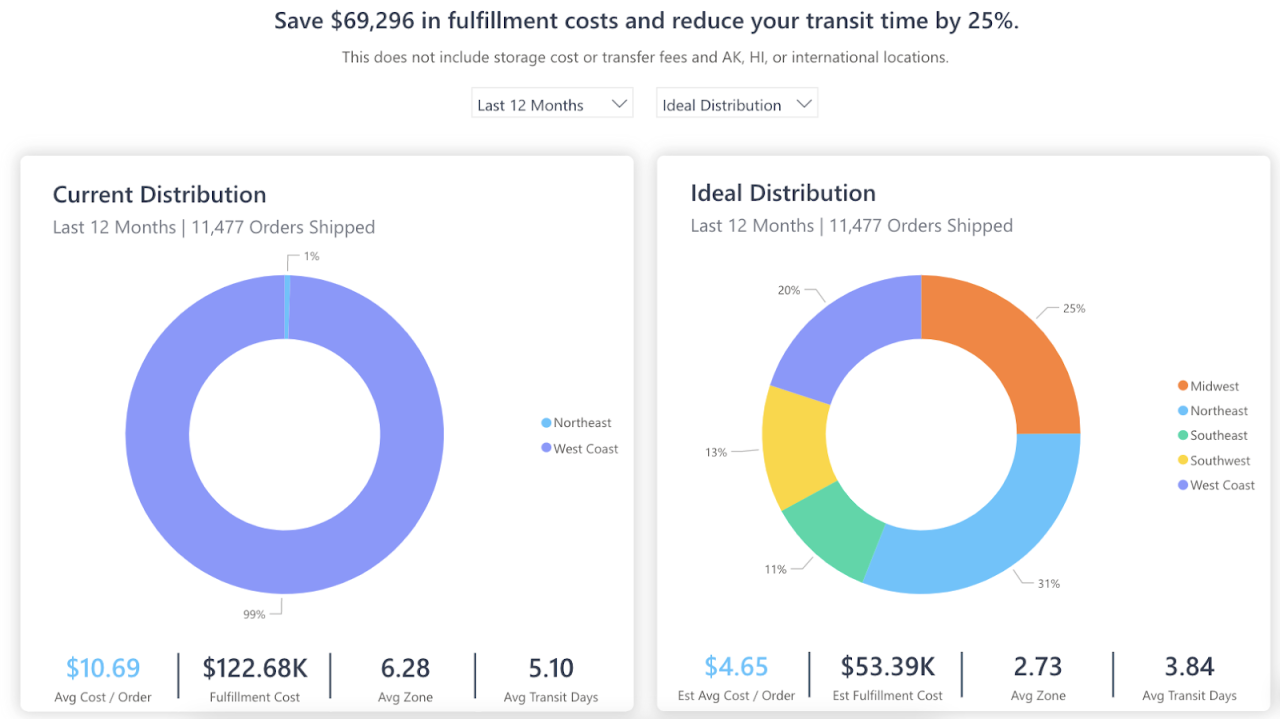

Real-time visibility across multiple locations

One of the key advantages of ShipBob’s platform is the ability to track inventory levels and status across multiple fulfillment centers in real-time. This comprehensive visibility mirrors the coverage of a wall-to-wall count, but on a much larger scale, encompassing your entire distribution network.

ShipBob’s technology continuously monitors inventory levels, providing up-to-the-minute data on stock quantities, allocation, and movement. This real-time tracking helps brands quickly identify discrepancies or potential issues, allowing for proactive resolution without the need for a full physical count.

This multi-location visibility also supports strategic inventory distribution decisions. By analyzing stock levels and demand patterns across your network, you can optimize your inventory allocation to ensure the right products are in the right places at the right times.

“One of my favorite parts of ShipBob’s solution is the analytics I get through the ShipBob dashboard. I use the reporting constantly, especially to track my stock. It’s even helping me get better at inventory forecasting. Before, I was just fumbling through the demand planning process and just ordering inventory based on what sold out. But now I have insight into metrics like SKU velocity and inventory days on hand, and I’m using that to decide what to reorder and how much of it I need. That helps a lot, especially now that the brand is scaling and I’m ordering my products in bigger batches.”

Luke Rolls, Founder of The Protein Pancake

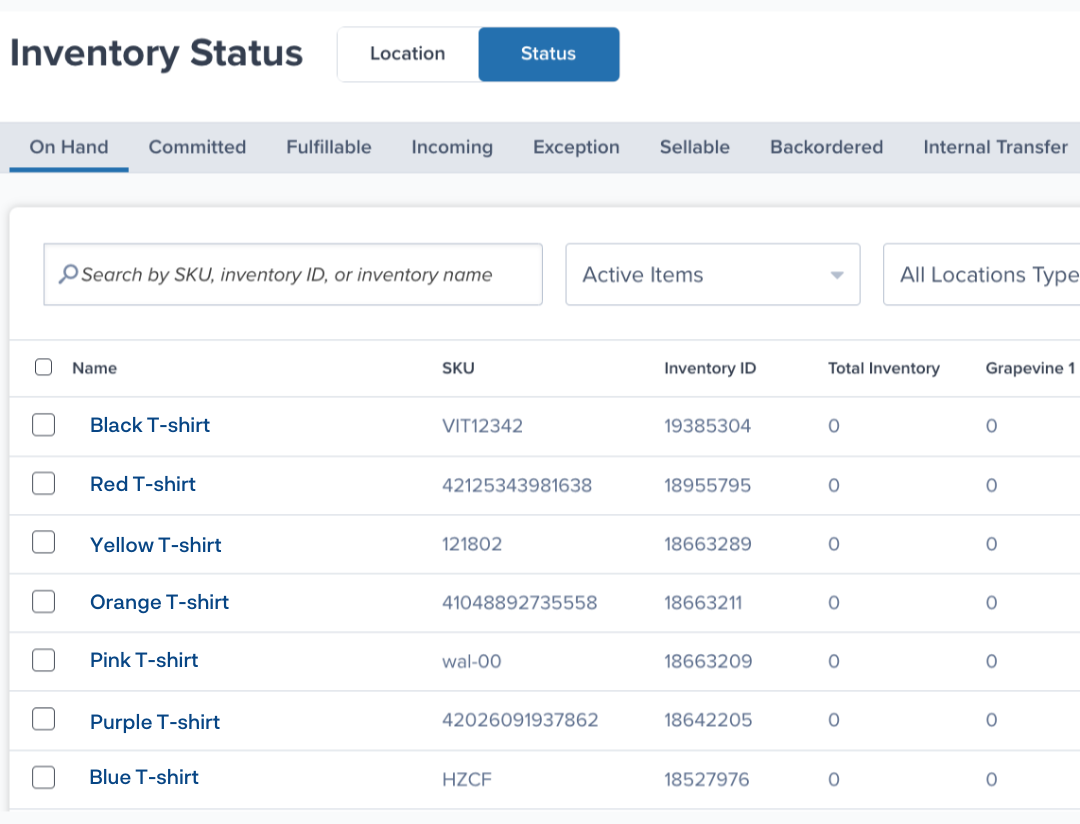

Integrated inventory status page

ShipBob’s integrated inventory status page provides a centralized view of your inventory across all locations, with detailed status categories like On Hand, Committed, Fulfillable, and more. This comprehensive dashboard gives you a “wall-to-wall” perspective of your inventory, without the need for a physical count.

By consolidating your inventory data in a single, easy-to-use interface, ShipBob helps you quickly check stock levels, identify potential shortages, and monitor inventory KPIs. This real-time visibility eliminates the need for manual reconciliation across multiple systems, reducing the risk of errors and discrepancies.

The inventory status page also provides automatic updates and adjustments based on real-time order and fulfillment data. As orders are processed and inventory is consumed, the system dynamically updates stock levels and allocation, ensuring perpetual accuracy without the need for manual intervention.

“We have over 5,000 SKUs, but that hasn’t been a problem for us in working with ShipBob. Their dashboard gives us visibility to inventory management, which has been excellent. ShipBob’s inventory counts are very accurate to what’s on-hand, and we can always see what we have available there. We also have an integration between our ERP, NetSuite, and ShipBob, so inventory data is always being fed back into NetSuite for us to view inventory counts there.”

Charlotte Katona, President of Makesy

Automated workflows and scalable operations

ShipBob’s platform is built on a foundation of automated workflows and processes that ensure accuracy and efficiency at every stage of the fulfillment process. From receiving and putaway to picking, packing, and shipping, ShipBob’s technology streamlines and optimizes each step, minimizing the risk of errors and discrepancies.

These automated workflows mirror the thoroughness and precision of a wall-to-wall inventory approach, but with the added benefits of speed and scalability. By minimizing manual touchpoints and automating key processes, ShipBob reduces the need for frequent physical counts, while still maintaining a high level of accuracy.

As your business grows and your inventory expands, ShipBob’s infrastructure is designed to scale with you. With a network of strategically located fulfillment centers and flexible storage options, ShipBob can accommodate your increasing inventory needs without sacrificing visibility or accuracy.

“From the very beginning, I knew we would need a partner that also had fulfillment centers in or near all the countries we sell to – and the ones we want to expand into – so that I could cut shipping times and costs for those shoppers as well. That’s part of why we went with ShipBob: they have a huge global presence, including fulfillment centers in key markets like the UK, the US, and Canada. They had great coverage for the places we were selling and the places on our growth roadmap, so we could scale without a lot of complications.”

Luke Rolls, Founder of The Protein Pancake

For more information on how ShipBob can help you store, manage, and audit your inventory, click the button below to get in touch.

Wall-to-wall inventory FAQs

Here are answers to some of the most common questions about wall-to-wall inventory counts.

What is the difference between wall-to-wall inventory and cycle counting?

Wall-to-wall inventory is a comprehensive, one-time count of every item in a warehouse or store, providing a complete snapshot of stock levels at a specific point in time.

Cycle counting, on the other hand, is an ongoing process that counts a portion of inventory on a rotating schedule.

While wall-to-wall counts ensure 100% accuracy at a given moment, cycle counting aims to maintain accuracy over time by regularly verifying portions of stock.

Can I find wall-to-wall inventory services to handle the process for me?

Yes, there are specialized inventory counting services that can manage the entire wall-to-wall counting process for your business.

When evaluating third-party providers, look for experience in your industry, advanced technology, and a proven track record of accuracy. Keep in mind that even when outsourcing, you’ll still need to prepare internally and coordinate with the service provider.

If you’re already working with a fulfillment partner like ShipBob, they may be able to handle inventory counts on your behalf, reducing the need for a separate service.

How often should a retailer conduct a full inventory count?

The frequency of full inventory counts varies by industry and business type, but most retailers conduct wall-to-wall counts at least once a year, often at the end of the fiscal year for financial reporting.

High-volume businesses or those with complex inventory may count more frequently, while slower-moving inventory may require less frequent counts. Factors like SKU count, turnover rate, and regulatory requirements also influence counting schedules.

With ShipBob’s real-time inventory visibility, you may be able to reduce the frequency of manual counts while maintaining accuracy.

How do I minimize disruptions to regular operations during a full count?

To minimize operational disruptions during a wall-to-wall count, schedule the count during slower periods and communicate the timeline to all stakeholders in advance.

If possible, break the count into zones or sections, allowing partial operations to continue in unaffected areas. Prioritize counting based on operational impact, focusing on high-traffic areas during off-hours.

If you’re working with a fulfillment partner like ShipBob, their distributed network can help maintain operations during counts by leveraging multiple locations.

What is the best way to sync my inventory data with an ERP or WMS?

Most modern inventory management systems offer integration options with popular ERPs and WMSs, either through native connectors or API customization.

When evaluating tools, prioritize those with pre-built integrations for your specific systems to streamline implementation. Before the count, thoroughly test data flows between systems to ensure accuracy and troubleshoot any issues.

ShipBob’s platform offers native integrations with leading ecommerce platforms and ERPs, making it easy to sync inventory data across your tech stack.

How does ShipBob help maintain accurate stock levels across multiple sites?

ShipBob’s fulfillment platform provides real-time inventory visibility across its entire global network, centralizing stock data from multiple locations into a single view.

This approach eliminates the need for separate counts at each site, as inventory data is continuously updated as orders are processed. ShipBob’s receiving and quality control processes ensure accuracy from the moment inventory arrives, while its technology automatically tracks inventory movements across facilities.

With ShipBob, you can achieve the benefits of wall-to-wall inventory visibility without the operational disruptions of traditional manual counts.

What are the main causes of inventory discrepancies during wall-to-wall counts?

Common causes of inventory discrepancies include theft, damage, and administrative errors like incorrect receiving or shipping quantities.

Miscounts can also occur due to human error, particularly with similar-looking products or disorganized storage areas.

To identify discrepancies, compare counted quantities to recorded levels and investigate any variances beyond established thresholds.

ShipBob’s technology and processes are designed to minimize these common errors, with barcode scanning, real-time updates, and regular audits to maintain accuracy.