Verified & Reviewed

Published on January 22, 2026 Written By Meredith Flora

Published on January 22, 2026 Written By Meredith Flora

Subscribe for More

Stockpile inventory serves as your business’s insurance policy against the unpredictable. It’s the strategic reserve that keeps your operations running smoothly when standard inventory levels fall short, whether it’s from a viral social media moment or seasonal demand exceeding your forecasts.

This guide covers the essentials of stockpile inventory management, from understanding how it differs from regular inventory to implementing best practices for your business. You’ll discover when to build reserves, how to maintain optimal levels, which KPIs to track, and how modern fulfillment technology helps you manage stockpiles across multiple locations with better visibility and control.

What is stockpile inventory (and how is it different from standard inventory)?

Stockpile inventory is the strategic reserve of products that businesses maintain above and beyond their regular working inventory levels. Unlike standard inventory that’s actively cycling through your fulfillment process to meet current demand, stockpile inventory serves as a protective cushion against unexpected events (e.g., a sudden surge in orders, supply chain disruptions, or extended supplier lead times).

Think of it this way: if your working inventory is the cash in your wallet for daily expenses, your stockpile inventory is your emergency fund. It’s there when you need it, but you’re not dipping into it for routine operations.

This differs from other inventory concepts you might encounter:

- Safety stock typically refers to a smaller buffer built into your reorder calculations to prevent stockouts during normal demand fluctuations.

- Buffer stock often gets used interchangeably with safety stock, though some businesses use it to describe inventory held between production stages.

- Working inventory is what you’re actively selling and replenishing on your regular cycle.

The core purpose of stockpile inventory is risk mitigation. It’s your insurance policy against the unpredictable, protecting your ability to fulfill orders when standard inventory planning falls short. Whether you’re preparing for peak season, hedging against supplier delays, or ensuring you can capitalize on unexpected viral moments, a well-managed stockpile keeps your business running when others might have to turn customers away.

Industries that rely on stockpiles

While stockpile inventory management is valuable across many sectors, certain industries depend on it more heavily due to their unique operational requirements and risk profiles.

- Ecommerce and CPG brands often maintain stockpiles to handle seasonal spikes, promotional periods, and the increasingly common phenomenon of social media-driven demand surges. A beauty brand might stockpile ahead of holiday gift-giving season, while a fitness equipment company builds reserves before New Year’s resolution season kicks in.

- Government agencies and disaster relief organizations maintain stockpiles for entirely different reasons: their reserves must be ready to deploy at a moment’s notice for emergency response. These stockpiles often include medical supplies, emergency equipment, and essential goods with strict compliance requirements around minimum quantities and expiration date management.

- Manufacturers use stockpile inventory to protect against raw material shortages or component delays that could shut down production lines. For them, the cost of maintaining extra inventory is often far less than the cost of idle equipment and workers.

Each industry faces unique challenges with shelf life, compliance requirements, and demand patterns. Food and pharmaceutical companies must carefully manage expiration dates and rotation protocols. Electronics retailers worry about technological obsolescence. Fashion brands navigate seasonal relevance. Your stockpile strategy needs to account for these industry-specific factors.

Stockpile vs. standard inventory overview

| Aspect | Standard Inventory | Stockpile Inventory |

| Reorder Cadence | Regular, predictable cycles based on average demand | Irregular, based on risk assessment and strategic planning |

| Storage Strategy | Prime picking locations for efficiency | Can utilize overflow areas or separate facilities |

| Turnover Rate | High — ideally turning multiple times per month | Lower — may sit for months until needed |

| Cost Considerations | Focus on minimizing holding costs | Balance holding costs against stockout risks |

| Primary KPIs | Inventory turnover, days on hand | Service level maintenance, stockout prevention rate |

| Demand Planning | Based on historical sales and forecasts | Based on worst-case scenarios and risk tolerance |

The biggest challenges of stockpile inventory management

Without proper management, stockpile inventory can quickly transform from a strategic asset into a financial drain. Here are the four major hurdles brands face when maintaining inventory reserves:

Balancing overstock risk vs. stockout risk

Finding the sweet spot between too much and too little stockpile is perhaps the most challenging balancing act. Excessive reserves tie up capital and rack up carrying costs through storage fees, insurance, and obsolescence risk. Too little defeats the purpose entirely, leaving you vulnerable to stockouts when demand spikes or supply chains falter.

The solution lies in data-driven forecasting that sets optimal levels based on lead times, sales velocity, and seasonality for each SKU, a process that requires continuous monitoring as your business evolves.

Maintaining real-time visibility across locations

As you expand to multiple warehouses and sales channels, inventory tracking becomes exponentially more complex. Without a centralized system, you might face stockouts in one location while excess inventory sits in another.

Multi-channel selling compounds this challenge, as your Shopify store, Amazon listings, and wholesale accounts all draw from the same inventory pool. Modern warehouse management systems solve this by providing unified visibility. For example, when Pit Viper implemented ShipBob’s warehouse management system, they achieved 99.7% order accuracy, eliminating thousands of mispicks annually.

Managing damaged goods, returns, and shrinkage

Warehouse realities like product damage, returns, and shrinkage can silently erode your reserves. Without proper protocols for inspecting, quarantining, and processing these exceptions, your actual available stockpile may be significantly less than what’s recorded.

Effective management requires clear SOPs, dedicated quarantine zones, disposition codes for tracking reasons for removal, and barcode scanning for accurate movement tracking. Advanced systems can automate much of this process, ensuring your inventory counts remain reliable.

Forecasting unpredictable demand

Predicting the unpredictable presents a fundamental challenge. Stockpiles exist for unexpected scenarios, yet you need a framework to determine appropriate reserve levels.

Traditional forecasting often fails to account for sudden market shifts, viral social moments, or supply disruptions. The complexity multiplies when considering product lifecycles, seasonality, and regional demand variations.

Modern solutions like ShipBob’s Inventory Placement Program combine historical data with external factors to automatically distribute inventory based on actual order patterns, helping brands maintain appropriate regional stockpile levels without manual calculations and preventing both overstocking and stockouts.

7 best practices for proactive stockpile inventory management

Managing stockpile inventory effectively requires a strategic approach that balances protection against stockouts with the costs of holding extra inventory. Here are seven proven practices to help you maintain the right reserve levels while keeping costs under control.

1. Set clear service-level goals for your reserve

Before building your stockpile, define exactly what you’re protecting against. Establish specific days of cover targets for each product category. For instance, maintaining 30 days of inventory for your top sellers versus 14 days for slower-moving items.

Create a critical SKU list identifying which products absolutely cannot go out of stock, whether due to customer expectations, contractual obligations, or profit margins. Set reorder points that trigger replenishment before you dip into your stockpile, ensuring your reserve remains intact for true emergencies.

2. Use data-driven forecasting models

Relying on gut instinct for stockpile levels is a recipe for either excess inventory or stockouts. Instead, combine your historical sales data with external factors such as seasonality, marketing campaigns, and market trends to build more accurate forecasts.

Track key performance indicators, including inventory turnover rate (how quickly you’re selling through stock), shrinkage percentage (losses from damage, theft, or counting errors), and carrying cost as a percentage of inventory value. This data-driven approach helps you right-size your stockpile based on actual patterns rather than assumptions.

3. Distribute inventory across strategic locations

Storing all your stockpile in one location creates unnecessary risk and shipping costs. By distributing inventory, you can position products closer to customers while also protecting against regional disruptions. This strategy can reduce last-mile shipping costs significantly and cut transit times by up to 50%.

When you spread inventory across multiple fulfillment centers, whether through a fulfillment partner or your own facilities, you’re not only improving delivery speed but also building redundancy into your supply chain.

4. Adopt advanced measurement technologies

Traditional manual counting methods leave room for error, especially with large stockpiles. Modern technologies like drone-based inventory counts or LiDAR volume measurements can dramatically improve accuracy while reducing labor costs. These volumetric measurement tools are particularly useful for bulk inventory or for irregularly shaped products. The key is syncing this volumetric data with your standard unit counts in your warehouse management system, ensuring all stakeholders have access to the same accurate information.

5. Automate replenishment and allocation rules

Manual inventory management becomes increasingly error-prone as your business scales. Set up dynamic minimum and maximum inventory levels that automatically adjust based on sales velocity and lead times. Implement lot and batch tracking to manage expiration dates and ensure proper rotation. Configure your systems to automatically generate purchase orders when inventory hits predetermined thresholds. For businesses using Excel or ERP systems, ensure proper integration with your fulfillment operations to avoid sync issues that can lead to overselling or understocking.

6. Build SOPs for damaged goods and expirations

Your stockpile is only valuable if the inventory remains sellable. Develop standard operating procedures for handling damaged goods, including clear quarantine workflows that separate questionable inventory from sellable stock. Implement disposition codes that categorize why items are removed from inventory (damage, expiration, quality issues) to identify patterns and prevent future losses. Set up automated alerts for products approaching expiration dates, giving you time to move inventory through promotions or alternative channels before it becomes unsellable.

7. Monitor KPIs and run periodic ROI audits

What gets measured gets managed. Track critical metrics including shrinkage percentage, carrying cost per unit, fill rate, and working capital tied up in stockpile inventory. But don’t stop at tracking.

Regularly audit whether your stockpile strategy delivers positive ROI. Calculate the cost of holding extra inventory (storage, capital, obsolescence risk) against the benefits (prevented stockouts, maintained customer satisfaction, captured sales during demand spikes). This cost-benefit analysis helps you continuously optimize reserve levels, ensuring your stockpile remains an asset rather than a liability.

How ShipBob gives brands real-time control over stockpile inventory

Managing stockpile inventory becomes exponentially easier with the right technology and fulfillment infrastructure. Here’s how ShipBob’s platform delivers the strategic inventory management and flow brands need to maintain optimal reserves without the typical headaches.

WMS for in-house or outsourced stockpiles

ShipBob’s warehouse management system provides the foundation for effective stockpile control, whether you manage your own warehouse or outsource fulfillment. The intuitive platform gets you operational quickly. For instance, Bunker Branding imported and organized 200,000 SKUs without extensive training or implementation delays.

Gain granular control through optimized storage strategies, automated reorder point alerts, and real-time tracking across all locations. Designate specific zones for stockpile inventory, implement rotation rules to prevent expirations, and monitor your reserves in real time.

For self-managed warehouses, the system eliminates the need for spreadsheets and disconnected tools. Everything from receiving to cycle counting happens on a single unified platform, reducing errors and building confidence in your inventory data.

“We’ve always had a pretty low fulfillment error rate. But keeping that number low has become harder the larger we get. Now we have over 200,000 SKUs on our website. It became difficult to make sure everyone was doing fulfillment in the right way.

ShipBob’s WMS makes it almost impossible to do things wrong. Eliminating the potential for human error during picking and packing has been great. Last time I checked, our error rate was less than 1%. We’re shipping out over 10,000 orders per month.“

Clint Sanders, Vice President of Operations at Bunker Branding

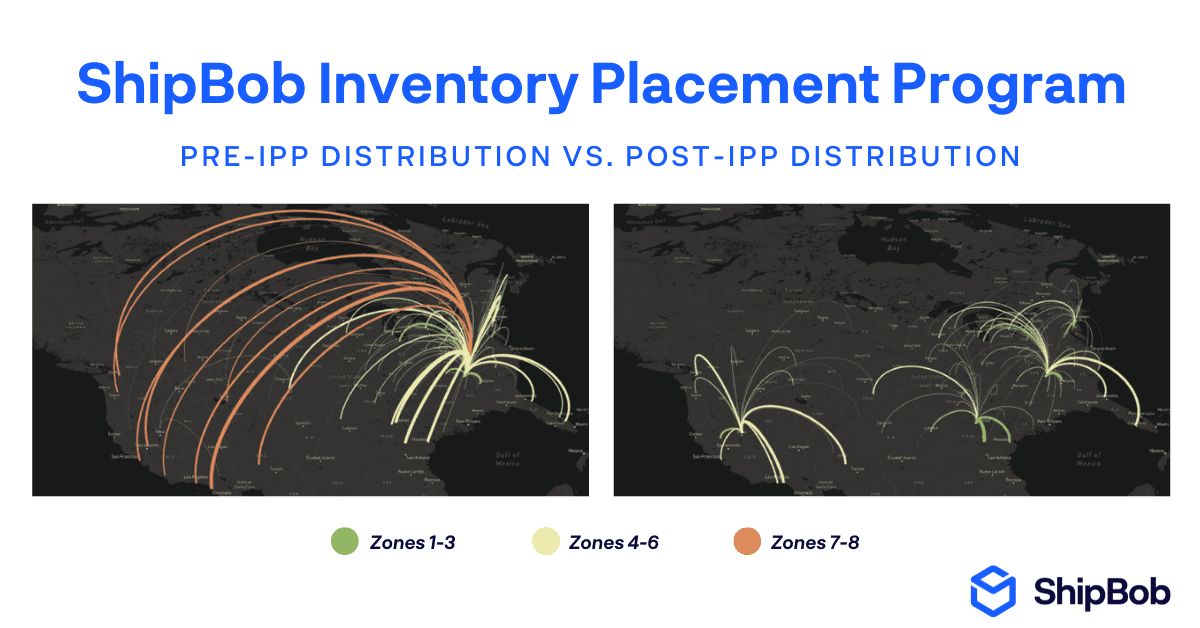

Inventory Placement Program for automated distribution

ShipBob’s Inventory Placement Program (IPP) eliminates the guesswork of where to store stockpile inventory for maximum effectiveness. Using historical order data and predictive algorithms, IPP automatically distributes your inventory across optimal fulfillment centers in the US.

The system analyzes shipping destinations and automatically suggests (or executes) inventory transfers to position stock closer to customers. Your stockpile isn’t gathering dust in one location; it’s strategically placed where you’re most likely to need it.

Brands using IPP have reduced shipping costs and cut delivery times by up to 50% while maintaining better regional stockpile coverage. The algorithm handles distribution calculations automatically, adjusting based on real-time demand patterns.

Omnichannel visibility and analytics suite

ShipBob’s platform provides a single source of truth that integrates with major ecommerce platforms like Shopify, Amazon, and B2B portals, ensuring accurate stockpile levels across all sales channels.

The analytics suite delivers actionable insights about stockpile performance through metrics such as days of stock on hand, SKU-level carrying costs, and stockout prevention rates. Custom reports identify which products need larger reserves and which might be overstocked.

Bloom Nutrition uses these analytics to maintain tight control over inventory investment and avoid surprise financial write-offs. The visibility helps them make informed decisions about tapping into stockpile versus placing emergency supplier orders.

“As you get larger, customer expectations increase – and as expectations increase, so does the importance of quality and service. So we weren’t just looking for the lowest cost-provider, but a partner that could also give our customers a really good experience that’s consistent with the high standards to which we hold our brand holds. That’s what’s going help a business scale in the long run, and that’s what ShipBob provides us.”

Neil Blewitt, SVP of Operations at Bloom Nutrition

Hybrid fulfillment flexibility

ShipBob’s hybrid fulfillment model gives you the flexibility to keep a critical stockpile in your own warehouse while leveraging ShipBob’s network for overflow or strategic reserve placement.

This approach lets you maintain direct control over essential inventory while using ShipBob to handle demand spikes without adding headcount or warehouse space. During peak seasons, quickly shift inventory to ShipBob’s facilities to handle increased volume, then scale back during slower periods.

The hybrid model works especially well for unique requirements, such as keeping customization in-house while ShipBob manages standard product stockpiles, or storing fast-moving inventory in your warehouse while positioning slower-moving reserves in ShipBob’s facilities.

All inventory is managed through a single platform, giving you unified reporting, consistent processes, and the ability to fulfill orders from the optimal location for each customer.

Get started with ShipBob

Connect with the ShipBob team to learn more about how our platform can help you manage and optimize inventory.

FAQs about stockpile inventory

Quick answers to common questions about managing stockpile inventory for your ecommerce business.

How much stockpile inventory should an ecommerce brand keep?

Aim for 30-60 days of coverage for your bestsellers, adjusting based on your specific needs. Consider lead times, seasonal demand, and cash flow when setting your levels.

High-velocity products or items with long lead times may need larger reserves, while slower-moving items or products with short shelf lives should have smaller stockpiles to avoid tying up capital.

What KPIs matter most for stockpile inventory management?

Focus on carrying cost percentage (what you’re spending to hold inventory), inventory turnover rate (how quickly stock moves), and stockout frequency (how often you run out).

Also track shrinkage rate, days of inventory on hand, and fill rate to ensure your stockpile strategy prevents stockouts without excessive holding costs.

How does ShipBob help manage stockpile inventory across multiple warehouses?

ShipBob’s platform shows real-time inventory levels across all fulfillment centers in a single dashboard. Track quantities by SKU, set automatic reorder points, and monitor inventory movement without switching between systems.

Set custom allocation rules to distribute stockpile inventory based on demand patterns, maintaining optimal levels at each location without managing multiple spreadsheets.

Can I integrate ShipBob’s WMS with my existing ERP or Excel workflows?

Yes, ShipBob’s WMS integrates with major ERP systems and accepts Excel data imports. Sync inventory levels, orders, and product information while maintaining your existing workflows.

Use APIs and pre-built connectors to keep data consistent across your tech stack. Many brands start with a simple SKU catalog import via CSV and expand their integration as they grow.

What technologies can improve stockpile counting accuracy?

Drone-mounted LiDAR sensors can quickly count bulk inventory in large spaces, capturing measurements and spotting discrepancies faster than manual counts.

RFID tags, automated barcode scanners, and computer vision also enhance accuracy. Choose solutions that integrate with your WMS to automatically update records and flag variances.

How do I prevent overstocking when building a reserve?

Use accurate demand forecasting based on historical data, seasonal trends, and upcoming promotions. Set maximum levels for each SKU with alerts when you approach these thresholds.

Conduct regular inventory audits, implement FIFO rotation, and establish clear rules for aging inventory to keep your stockpile fresh and minimize write-offs.

Does ShipBob support hybrid fulfillment models for partial stockpiles?

Yes, ShipBob supports keeping some inventory in your warehouse while storing overflow or strategic reserves in our fulfillment centers. Scale up during peak seasons without year-round warehouse commitments.

Route orders seamlessly between your facility and ShipBob’s network based on inventory availability and customer proximity, with full visibility across all locations through one unified dashboard.