Verified & Reviewed

Published on July 10, 2025 Written By Meredith Flora

Published on July 10, 2025 Written By Meredith Flora

Subscribe for More

Inventory accuracy is essential for ecommerce success, but keeping counts aligned with reality can be tricky.

That’s where stock checking and stocktaking come in. Both involve counting inventory, but they serve different purposes: stock checking is a targeted, routine process, while stocktaking is a full physical count conducted less frequently.

To stay agile and avoid costly inventory discrepancies, ecommerce brands need a smart blend of both. In this guide, we’ll break down the key differences, share best practices for each method, and highlight how ShipBob’s tech-driven fulfillment platform helps brands stay on top of their inventory with real-time visibility and built-in verification tools.

Stock checking vs. stocktaking

Stock checking and stocktaking are two essential inventory management processes that help businesses maintain accurate stock levels and prevent costly discrepancies. While both methods involve counting and verifying inventory quantities, they serve distinct purposes and are performed at different frequencies.

To maintain optimal inventory accuracy and efficiency, businesses need to implement a balanced approach that incorporates both regular stock checks and periodic full stocktakes. The rise of digital inventory management tools and automated systems has transformed these traditionally manual processes, enabling real-time visibility and streamlined verification workflows.

Stock checking recap

Stock checking is a targeted, routine process that focuses on specific items, locations, or categories within a warehouse or storage facility. It’s typically a quick, partial count that can be performed without significantly disrupting daily operations.

Businesses often conduct stock checks on a regular schedule or in response to specific triggers, such as low stock alerts or discrepancies between recorded and actual quantities. The primary goal of stock checking is to verify that on-hand quantities match system records, particularly for high-value or fast-moving items.

Stocktaking recap

Stocktaking is a comprehensive, end-to-end count of all inventory in storage. It’s a more formal and thorough process that often ties into accounting and financial reporting requirements.

This process typically requires more planning, resources, and potential operational adjustments to complete successfully. By counting every item in stock, businesses can “reset” their inventory accuracy across the entire organization and identify any discrepancies or issues that need addressing.

Key differences between stock checking and stocktaking

While both stock checking and stocktaking are essential inventory management processes, they differ in several key aspects. Understanding these distinctions is crucial for businesses to implement the right method at the right time, ensuring optimal inventory accuracy and operational efficiency.

Scope and coverage

Stock checking is a targeted, partial inventory count that focuses on specific items, locations, or categories. For example, a business might conduct a stock check on its top 20% of SKUs that drive 80% of sales. This targeted approach allows for more frequent checks without disrupting the entire operation.

In contrast, stocktaking is a comprehensive, complete inventory count that covers every item in storage, including slow-moving and obsolete products. This process ensures that all inventory is accounted for, providing a full picture of the company’s stock levels.

Frequency and timing

Stock checking typically happens more frequently, such as daily or weekly, depending on the business size, complexity, and sales volume. This regular cadence helps maintain inventory accuracy and prevents stockouts by identifying discrepancies quickly.

On the other hand, stocktaking is usually conducted less frequently, such as quarterly or annually. The optimal frequency depends on factors like business size, industry regulations, and financial reporting requirements. Some businesses adopt a continuous stocktaking approach, where they count a portion of their inventory on a rolling basis throughout the year.

When determining the timing of stock checks and stocktakes, businesses should consider their sales cycles and operational demands. Stock checks are best performed during peak seasons to ensure inventory accuracy, while stocktaking is often scheduled during slower periods to minimize disruption.

Purpose and business objectives

The primary focus of stock checking is maintaining operational accuracy and preventing stockouts. By regularly verifying stock levels for high-demand items, businesses can quickly identify and resolve discrepancies, ensuring that the right products are available when customers need them.

Stocktaking, however, has a broader purpose that extends beyond day-to-day operations. This comprehensive process supports financial reporting, loss prevention, and complete inventory reconciliation. Stocktaking creates an accurate picture of the company’s entire inventory and helps businesses make informed decisions, comply with accounting standards, and identify opportunities for process improvements.

Both methods contribute to customer experience and order fulfillment, but in different ways. Stock checking helps maintain a steady flow of goods, preventing delays and backorders, while stocktaking ensures the overall accuracy of the company’s inventory records, which is essential for long-term planning and financial stability.

Resource requirements and disruption

Stock checking typically requires less labor, time, and technology compared to stocktaking, as it deals with a smaller subset of inventory. This targeted approach allows businesses to integrate stock checks into their daily operations with minimal disruption, as the checks can be performed quickly and efficiently.

Stocktaking, on the other hand, often requires more planning, labor, and potential operational adjustments. Because it involves counting every item in storage, businesses may need to allocate additional staff, equipment, and time to complete the process. In some cases, operations may need to be temporarily suspended or scaled back to accommodate the count.

To minimize disruption during both stock checking and stocktaking, businesses should:

- Plan ahead and communicate the schedule to all relevant stakeholders

- Allocate sufficient resources and train staff on proper procedures

- Leverage technology to streamline the counting process and reduce manual errors

- Consider conducting partial counts or cycle counting to spread the workload over time

By understanding the unique resource requirements and potential for disruption associated with each method, businesses can develop strategies to optimize their inventory verification processes and maintain smooth operations.

Effective approaches to inventory stock checking

As businesses grow and their inventory management needs evolve, it’s important to adopt stock checking methodologies that align with operational realities. While traditional approaches like annual full inventory counts still have their place, the rise of digital tools and automated systems has transformed the landscape of inventory verification.

Whether you opt for periodic cycle counting, continuous verification, or a hybrid model, the key is to find a system that integrates seamlessly with your day-to-day operations and provides the level of control you need to drive business success.

Annual full inventory counts

For businesses with smaller inventories or specific regulatory requirements, the traditional approach of conducting a comprehensive annual stocktake remains a viable option. This method involves shutting down operations for a set period to perform a complete count of all items in storage.

While this approach provides a clear “reset” point for inventory accuracy, it does come with some drawbacks. The main challenge is the operational disruption caused by pausing fulfillment activities, which can impact customer experience and revenue. Additionally, counting large volumes of inventory in a single event can be time-consuming and prone to human error.

To mitigate these issues, businesses opting for annual stocktakes should focus on meticulous planning and preparation. This includes organizing the physical counting space, assigning clear roles and responsibilities to team members, and developing a systematic approach to reconciling discrepancies. By investing time upfront to streamline the process, brands can minimize downtime and ensure a more accurate outcome.

Periodic cycle counting

Cycle counting offers a more flexible and efficient alternative to annual stocktakes. This approach involves breaking inventory down into smaller, more manageable subsets and counting them on a rotating schedule throughout the year. By spreading the counting workload over time, businesses can maintain a higher level of accuracy without causing significant operational disruption.

One popular cycle counting method is ABC analysis, which categorizes inventory based on value and transaction volume. Under this system, high-value, fast-moving items (A) are counted more frequently than medium-priority (B) or low-priority (C) items. This ensures that the most critical products are closely monitored while optimizing labor resources.

To implement an effective cycle counting program, businesses should start by establishing clear parameters for each counting cycle. This includes setting thresholds for inventory value, transaction volume, and variance tolerance. By defining these rules upfront, teams can prioritize their efforts and quickly identify discrepancies that warrant further investigation.

Continuous inventory verification

Today, many businesses are shifting towards a model of continuous inventory verification. This approach leverages technology to monitor stock levels in real-time, with automated systems that track inbound and outbound movements as they occur.

Under a continuous verification model, the focus shifts from periodic physical counts to exception-based management. By setting thresholds for acceptable variances, the system can automatically flag discrepancies that require human intervention. This allows businesses to address potential issues proactively, rather than waiting for a scheduled counting event.

Continuous verification is particularly well-suited to businesses with high inventory turnover and complex, multi-channel operations. By providing real-time visibility across the entire supply chain, this approach empowers teams to make informed decisions and respond quickly to changing demand patterns. It also enables a more seamless, uninterrupted fulfillment experience for customers.

Hybrid model for growing ecommerce brands

For many ecommerce businesses, the optimal approach to inventory verification lies somewhere between the extremes of annual stocktakes and fully automated continuous monitoring. A hybrid model that combines elements of both methodologies can provide the flexibility and control needed to scale effectively.

Under a hybrid approach, businesses typically rely on a foundation of real-time, system-driven stock checks to maintain day-to-day accuracy. This ensures that high-priority items and fast-moving SKUs are closely monitored, with any discrepancies quickly flagged for investigation. These automated checks are then supplemented by periodic, targeted cycle counts to verify slower-moving items and reconcile overall inventory levels.

The exact balance between continuous monitoring and physical counting will depend on factors such as business size, product mix, and operational complexity. As brands grow and evolve, they may need to adjust their approach to ensure they’re striking the right balance between accuracy and efficiency.

Ultimately, the key to success with a hybrid model lies in developing a clear, data-driven framework for inventory verification. By setting thresholds for automated checks, establishing a schedule for periodic counts, and defining protocols for discrepancy resolution, businesses can create a system that scales with their needs over time. This flexibility is particularly valuable for ecommerce brands navigating the challenges of rapid growth and changing customer expectations.

“We rely heavily on ShipBob for inventory tracking and forecasting and that’s been a key part of our partnership. Our area of expertise is not logistics or inventory management, so we lean on ShipBob a lot for that. We’ve learned so much about this industry since working with ShipBob, as they are true supply chain experts, which has been good for everyone on our team. When thinking about fulfillment, there’s such a focus on the packing and shipping aspect that the inventory management piece can often go unnoticed. But ShipBob’s ability to help us track and reconcile inventory is really great.”

– Callie Tivnan, E-commerce Manager, and Christina Williams, Customer Success Manager at Barefaced

When to use stock checking vs. stocktaking

While stock checking and stocktaking serve distinct purposes, most businesses need a combination of both methods to maintain optimal inventory accuracy. The key is to find the right balance based on factors like business size, product mix, and sales volume. By understanding when to prioritize each approach, brands can develop a comprehensive inventory verification strategy that scales with their growth.

Business size and growth stage considerations

The size and maturity of your business will significantly influence how you approach stock verification. For startups and small businesses with limited SKUs, manual stock checks may be sufficient to maintain accuracy. However, as order volume increases and inventory expands, the need for more formal stocktaking processes becomes evident.

As a general rule, businesses should consider transitioning to systematic stocktaking when:

- SKU count exceeds 100-200 unique products

- Average daily order volume surpasses 50-100 orders

- Inventory is stored across multiple locations or channels

For enterprise-level organizations with complex supply chains, a robust stocktaking system is essential. This may involve a combination of periodic full counts and targeted cycle counting, supported by advanced inventory management software.

Product-specific factors

The characteristics of your product catalog also play a role in determining the optimal balance between stock checking and stocktaking. Consider the following factors when developing your verification strategy:

- Product value: High-value items may require more frequent stock checks to prevent costly discrepancies. Conversely, lower-value products can be counted less often without significant financial risk.

- Perishability: Products with short shelf lives, such as food or cosmetics, demand more rigorous verification to ensure accuracy and minimize waste.

- Seasonality: Seasonal products may benefit from targeted stock checks before and after peak selling periods to optimize inventory levels.

- Demand variability: Items with unpredictable or fluctuating demand patterns may require more frequent checks to prevent stockouts or overstocking.

By segmenting your inventory based on these characteristics, you can prioritize verification efforts and allocate resources effectively.

Data-driven triggers for each method

In addition to business and product-specific factors, data-driven insights can help determine when to perform stock checks or stocktakes. Key performance indicators (KPIs) such as inventory turnover rate, stock-to-sales ratio, and inventory shrinkage can provide valuable context for verification decisions.

For example, if your inventory shrinkage rate exceeds industry benchmarks, it may indicate a need for more frequent stock checks to identify the root cause. Similarly, if your stock-to-sales ratio is consistently high, a comprehensive stocktake can help identify slow-moving items and optimize inventory levels.

To leverage data effectively, establish thresholds for each KPI that trigger verification activities. This might include:

- Conducting a stock check when inventory turnover falls below a certain threshold

- Initiating a full stocktake when shrinkage exceeds a set percentage

- Reviewing sales data to identify items that require more frequent counting

By combining business context, product knowledge, and data-driven insights, you can develop a tailored approach to stock checking and stocktaking that meets your unique needs.

How ShipBob supports inventory verification

ShipBob’s ecommerce fulfillment platform is designed to support accurate and efficient inventory verification, whether you’re conducting routine stock checks or comprehensive stocktakes. By leveraging advanced technology and established best practices, ShipBob helps merchants maintain tight control over their inventory while minimizing operational disruptions.

Real-time inventory visibility

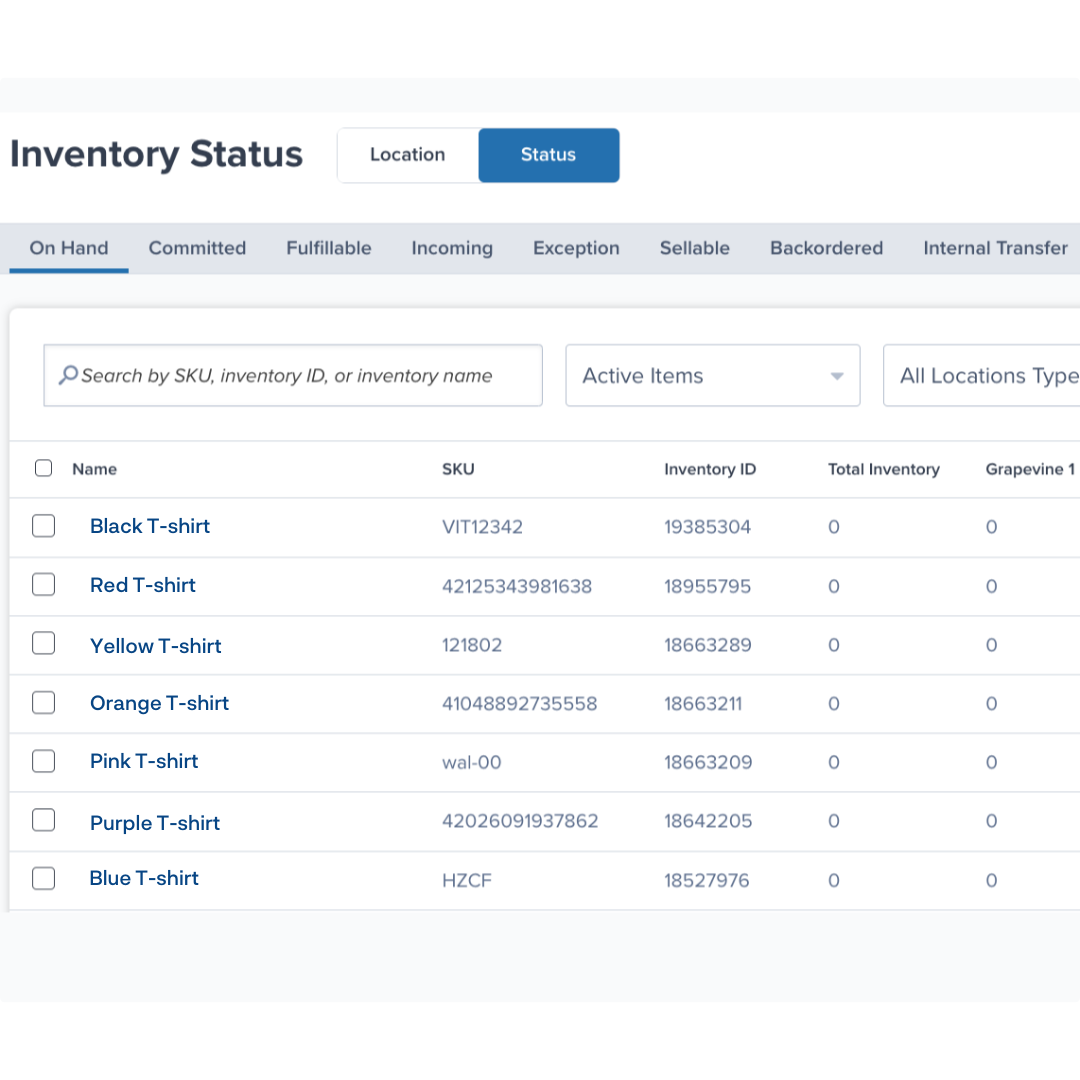

ShipBob’s Inventory Status Page provides merchants with up-to-the-minute information on stock levels across various statuses, including On Hand, Committed, Fulfillable, Incoming, Exception, and Internal Transfer. This real-time visibility allows businesses to quickly verify inventory at any time without disrupting daily operations.

By monitoring stock levels and setting up automated alerts, merchants can proactively prevent stockouts and overstocks, ensuring a positive customer experience and optimizing working capital.

“We have over 5,000 SKUs, but that hasn’t been a problem for us in working with ShipBob. Their dashboard gives us visibility to inventory management, which has been excellent. ShipBob’s inventory counts are very accurate to what’s on-hand, and we can always see what we have available there. We also have an integration between our ERP, NetSuite, and ShipBob, so inventory data is always being fed back into NetSuite for us to view inventory counts there.”

– Charlotte Katona, President of Makesy

Warehouse receiving and verification processes

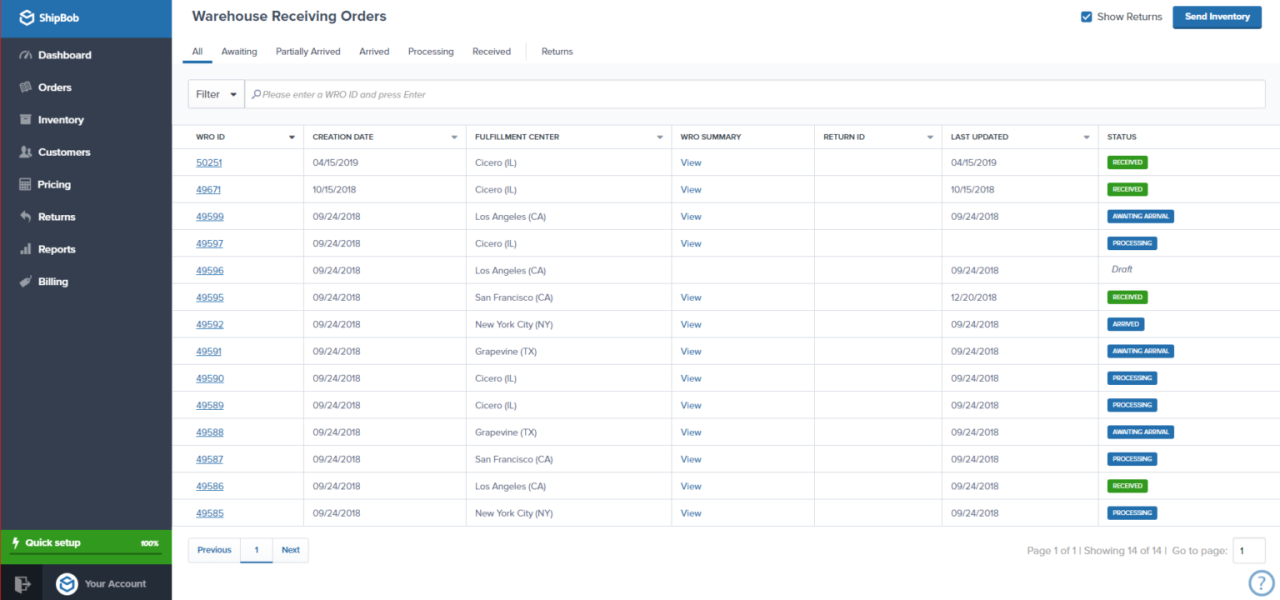

ShipBob’s robust warehouse receiving order (WRO) process ensures that incoming inventory is accurately verified and recorded from the moment it arrives. Items are counted against submitted orders and discrepancies are promptly investigated and resolved.

This initial verification step prevents downstream inventory errors and creates a detailed inventory audit trail for future reference. By establishing accurate inventory records from the start, ShipBob helps merchants maintain a high level of precision throughout the fulfillment process.

Multi-facility inventory management

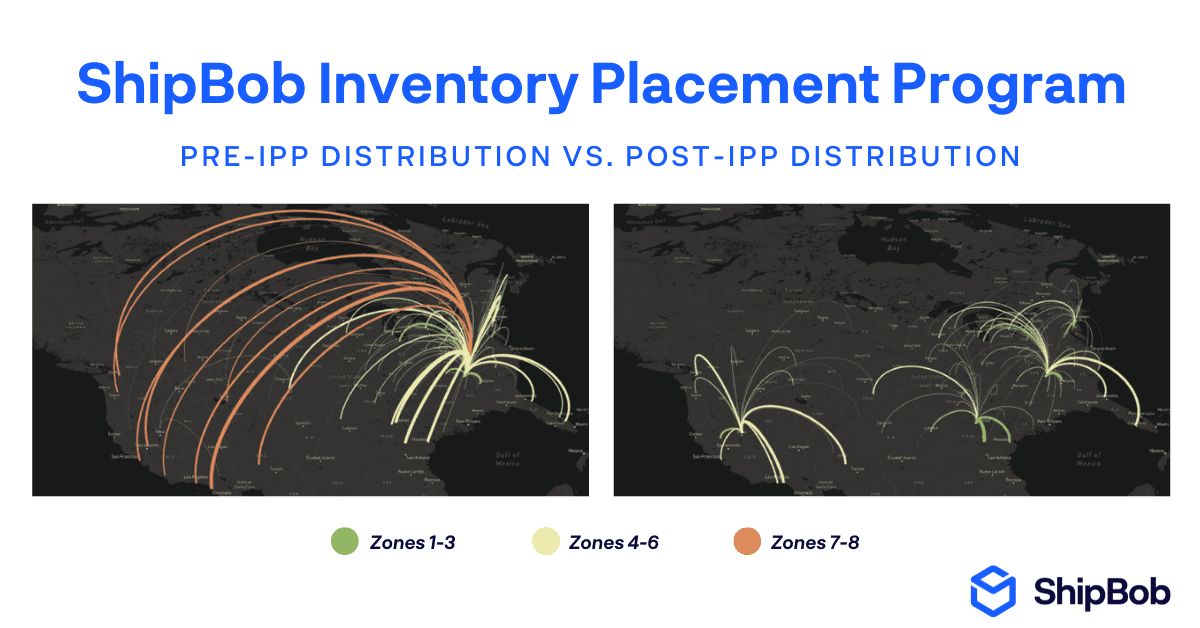

For brands with inventory distributed across multiple of ShipBob’s 60+ fulfillment centers, ShipBob provides centralized visibility and control. Merchants can easily view and verify stock levels at each location, ensuring accuracy across their entire distribution network.

ShipBob’s Inventory Placement Program (IPP) automates and optimizes inventory placement and distribution throughout the US. IPP automatically routes orders to the closest fulfillment center with available stock to reduce shipping costs and transit times while maintaining inventory accuracy.

Discrepancy resolution and exception handling

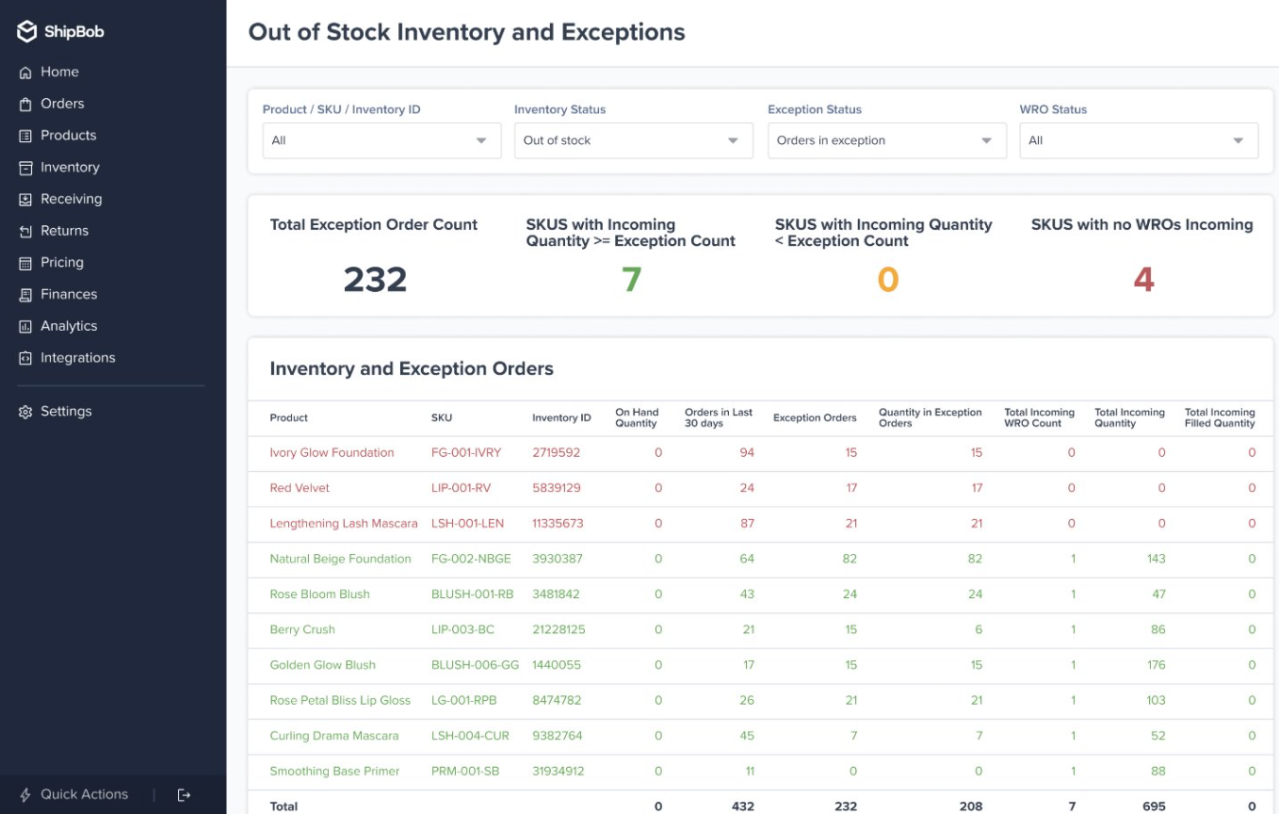

In the event of an inventory discrepancy, ShipBob’s platform provides the tools and processes needed to quickly investigate and resolve the issue. The system compares “Expected” versus “Counted” quantities, highlighting any variances that require attention.

Merchants can access detailed reports and audit trails to help pinpoint the source of the discrepancy and take corrective action. By proactively addressing exceptions, ShipBob helps businesses maintain accurate inventory records and prevent potential customer service issues.

From stocktaking to shipping, ShipBob has you covered

Say goodbye to manual errors and hello to automated inventory management. Learn how ShipBob can help optimize your operations.

Stock checking vs stocktaking FAQs

Below are answers to some of your common questions and queries about stock checking and stocktaking.

How often should I perform stock checks vs. full stocktakes?

The optimal frequency for stock checks and full stocktakes depends on factors like business size, product type, and sales volume. Smaller businesses with limited SKUs may be able to rely on periodic full counts, while larger operations will likely need a combination of frequent targeted checks and less frequent comprehensive stocktakes.

As a general guideline, aim to perform stock checks on high-value or fast-moving items at least weekly, while slower-moving products can be checked monthly or quarterly. Full stocktakes are typically conducted annually, but businesses with complex inventory or strict reporting requirements may need to do them more often. Technology solutions that provide real-time visibility can help you determine the most effective frequency for your business.

When should a growing business transition from manual checks to systematic stocktaking?

As your business grows, you’ll likely reach a point where manual stock checks become inefficient and error-prone. Key indicators that it’s time to transition to more systematic processes include:

- Consistently high order volumes that make it difficult to keep up with manual counts

- Expanding SKU counts that increase the complexity of inventory management

- Multiple sales channels or fulfillment locations that require centralized inventory control

If you find yourself struggling to maintain accuracy with manual methods or spending too much time on inventory verification, it’s probably time to invest in technology solutions that can automate and streamline the process.

What’s the best way to handle discrepancies discovered during counts?

Discrepancies between expected and actual stock levels are inevitable, but how you handle them can make a big difference in maintaining inventory accuracy over time. When variances are discovered during a count, take a systematic approach to investigation:

- Verify the accuracy of the count itself to rule out human error

- Check for recent transactions or movements that might explain the discrepancy

- Look for patterns or trends that might indicate underlying issues like theft, damage, or miscategorization

- Document the discrepancy and any steps taken to investigate or resolve it

Once you’ve identified the cause of the variance, take corrective action to update your records and prevent similar issues in the future. This might involve adjusting processes, implementing new controls, or providing additional training for staff.

How can I minimize disruption during a full stocktake?

Full stocktakes can be disruptive to normal operations, but careful planning and preparation can help minimize the impact. Some strategies to consider:

- Schedule counts for slower periods or outside of normal business hours

- Communicate with customers and suppliers in advance about potential delays

- Assign dedicated teams to the stocktake so that other staff can focus on daily operations

- Organize your physical space and inventory records to make the counting process as efficient as possible

- Use technology solutions like barcode scanners or inventory management software to speed up the process

With the right approach, you can complete a full stocktake without significant disruption to your business.

How does real-time inventory tracking change traditional stock verification methods?

Real-time inventory tracking systems provide continuous visibility into stock levels, reducing the need for manual checks and counts. With up-to-the-minute data on inventory movements, you can identify discrepancies as they happen and take immediate action to investigate and resolve them.

This shifts the focus of stock verification from scheduled checks to exception-based management; allowing you to use real-time data to trigger targeted checks when unusual activity or variances are detected. This lets you catch and correct issues faster, maintaining a higher level of overall accuracy.

How does ShipBob handle inventory verification across multiple fulfillment centers?

ShipBob’s platform is designed to maintain inventory accuracy across our entire fulfillment network. When you store inventory in multiple ShipBob facilities, our system synchronizes data in real-time to provide a centralized view of your stock levels.

This enables you to easily verify inventory quantities across locations without the need for manual reconciliation. From your ShipBob dashboard, you can view up-to-the-minute stock levels for each facility, drill down into specific SKUs, and identify any discrepancies or unusual activity.

This approach supports both routine stock checks and formal stocktakes. For day-to-day verification, you can quickly spot-check inventory levels in each facility and compare them to your expected quantities. And when it’s time for a full count, ShipBob’s team can conduct the stocktake on your behalf, providing you with a complete reconciliation of your inventory across all locations.