Warehouse operations get complicated. That’s why lots of brands use a warehouse management system, or WMS, to get better visibility and control over your warehousing operations, helping you streamline workflows and improve efficiency.

But getting a WMS up and running is easier said than done. It takes a lot of work, and could involves expensive downtime and steep learning curves if not done correctly.

In this post, we’ll walk through the steps to successfully set up a WMS. We also provide you with a checklist that will guide implementation, and make the process as seamless and streamlined as possible.

The importance of thorough warehouse management system implementation (vs. basic WMS setup)

Implementing a warehouse management system is more than simply installing software and running with it. The system needs to be carefully integrated into different aspects of your warehouse operations, with hands-on training to help users gain experience using it.

It’s important to be thorough take your time and be thorough during implementation, because a well-thought out and executed implementation will:

- Minimize issues and troubleshooting: If the WMS isn’t properly integrated into your warehouse workflow, you risk creating delays and errors to clean up.

- Increase efficiency: A thorough WMS implementation process lets you customize the WMS fits into your operations according to your exact needs for greater warehouse efficiency.

- Shorten the learning curve: Hands-on learning experiences and tutorial sessions teach workers to adopt the system, and make it easier for them to use the new system in their day-to-day tasks.

- Reduce downtime: Taking the time upfront to test and optimize the WMS means less issues pop up after the go-live phase. This prevents more downtime int he future, which boosts your warehouse productivity.

“Onboarding with ShipBob’s WMS was our first time connecting to a warehouse management system, so we had to get data and SKUs synced with the platform, do warehouse mapping, and get our various integrations (like Shopify and NetSuite) set up.

Once everything was in place, we just had to flip a switch to start fulfilling orders. The ShipBob team even came out to our facility for a week to show us how to do everything. It was a super straightforward process. It’s a very plug-and-play solution that is also customizable to our workflows.”

Jourdan Davis, Operations Manager at Pit Viper

Common WMS implementation challenges

WMS deployment is an intensive and time-consuming process — and comes with lots of challenges. Here are some of the most common stumbling blocks on the road to implementation that you should prepare for.

Resistance to change

When your warehouse staff is used to doing things a certain way, you may face some resistance when implementing a new system. Although clunky and outdated, your existing technology is familiar; a new WMS, on the other hand, presents more work and a learning curve.

Providing sufficient training and support is crucial to help them understand the benefits of a new WMS so they can embrace the change.

Data migration errors

Missing or inaccurate data is not uncommon when migrating to a new WMS. A comprehensive data backup is necessary to protect against any data loss that might occur during migration.

Technical issues

Hardware compatibility issues and software glitches are also common when integrating a new WMS. To minimize bugs, make sure your WMS is compatible with your existing tech stack before making the move. Quickly identify and resolve any software glitches during implementation to prevent issues further down the line.

Adaptation challenges

Even after system implementation, employees may have a hard time adapting to it and incorporating it into their day-to-day jobs. Ask for feedback on user challenges — both immediately and a few months in — and provide targeted training sessions for underutilized features.

Unrealistic timelines

WMS implementation takes time and involves multiple phases. If you set unrealistic timelines or milestones, you may be tempted to rush through these phases, which leads to incomplete deployment or insufficient training. Instead, try to keep a realistic timeline for implementing a new WMS and build in time to allow flexibility for unforeseen delays.

5-phase WMS implementation roadmap

There are 5 main phases in a smooth WMS implementation. We’ll break down each phase, and share pro tips for mastering them.

Phase 1: Planning and requirements

The first phase is all about planning: getting organized and thinking through what your business really needs before setting up your new warehouse management system (WMS). It’s kind of like making a game plan, so you know what to expect and what to aim for.

Start by talking with stakeholders from different teams — especially the ones who will be using the system every day. Ask them what’s working, what’s not, and what tools they wish they had. This helps you make a list of the most important features your new system should have.

For example, maybe your team struggles with sending out the right orders, or maybe shipping is just too slow. Knowing these pain points helps you look for a system that can fix them.

Next, build a team to lead the implementation. These are the people who will keep things on track, so make sure everyone has a clear role and knows what they’re responsible for.

You’ll also want to set a timeline for the project. Break the work into steps and figure out when each one needs to be done. This makes it easier to plan a schedule, allocate resources, and keep everything moving forward.

Phase 2: System configuration and integration

The next step is to configure your WMS so that it works the way your business needs it to. This involves making sure that the WMS integrates directly with all your other tools.

Your WMS should seamlessly connect with your sales channels (e.g., your online store, Amazon, and other marketplaces), your inventory management software, and any shipping tools you use. That way, you don’t have to jump between different systems to manage orders, track inventory, or ship packages.

ShipBob’s WMS, for example, connects with dozens of popular ecommerce tools, so you can manage your inventory, orders, fulfillment, and shipping from one platform.

There are also other add-ons you can use, like tools for marketing, customer relationship management (CRM), custom packaging, web design, accounting, and more—basically, whatever you need to run your business more easily. Your WMS should integrate with these as well.

Phase 3: Training and change management

This step is all about preparing your warehouse team for the transition, and helping them get comfortable with the new system. This can be one of the trickiest parts of any implementation — but good training and hands-on practice make it much easier.

Everyone learns differently, so it’s important to train each group based on what they actually do. For example, your picking team should learn how the WMS helps them optimize pick paths and verify pick lists faster. Your packing team might need to learn how the WMS determines the ideal box size for each unique order.

It’s also smart to have a plan to help people adjust to the changes. Keep your team involved in the process, check in regularly, and be ready to help anyone who needs extra support.

If you’re using something like ShipBob’s WMS, you also get help with onboarding. Their team goes beyond just setting up the system—they take a close look at your warehouse and suggest ways to make things run more smoothly. This can help speed up your order process and make the whole team more efficient.

In this stage, hands-on help hands-on help from experts can make all the difference. That’s why ShipBob offers dedicated onboarding support to brands implementing ShipBob WMS in their own warehouses — and not just basic help. ShipBob’s boots-on-the-ground team helps you audit your warehouse, identify areas to optimize, and suggest ways to improve your warehouse set up to improve fulfillment workflows and boost efficiency.

Phase 4: Pilot testing and go-live

Before you fully switch over to the new WMS, you need to test it to make sure everything works the way it should. Try out daily warehousing tasks, like receiving inventory, putaway, picking, packing, and shipping. This helps you see how the WMS handles all parts of your warehouse process.

This is also the time when your team gets to use the system and give feedback. They might spot glitches, pinpoint workflow bottlenecks, or suggest ways to make the system easier to use. That way, you can fix those problems before launching the software across your entire warehouse.

Once the bugs are worked out, it’s time for the big moment: your go-live. That’s when you officially start using the WMS to run your warehouse. If possible, schedule go-live during a slower time or off season, so if anything goes wrong, it won’t cause too many issues. Keep everyone in the loop about when it’s happening and what to expect.

Also, make sure you’ve got a support team ready to help. This should include both your own IT team and a representative from your WMS provider, just in case any issues pop up right after launch.

Phase 5: Post-implementation optimizations

Just because the system is up and running doesn’t mean the work is done. After the launch, you’ll need some time to make sure everything’s working smoothly — and figure out how to get the most out of the new WMS.

Keep an eye on how things are going by tracking warehouse KPIs (like on-time fulfillment rate, order accuracy, picking accuracy, and more). These metrics give you insight into your warehouse’s operational performance, and help you pinpoint what’s going well and what areas you might still need to improve.

You should also check in with your team regularly. Ask how the system’s working for them and if they’ve run into any problems. Their feedback can help you make small changes that lead to even better warehouse optimizations over time.

WMS implementation checklist

With so many moving parts involved in the WMS implementation process, it’s easy for some things to fall through the cracks. Here’s a handy WMS implementation checklist to ensure you have everything covered.

Cross-functional project team roles

As you prepare for implementation, make sure to set up a cross-functional team to oversee the process. You’ll want to:

- Involve representatives from IT, operations, finance, and other relevant departments.

- Choose representatives with significant influence in their respective departments. Think: Director of Fulfillment, Warehouse Managers, Director of Logistics, etc.

- Assign roles and specify the responsibilities of each team member.

Budgeting and timeline management

WMS implementation projects tend to be time-consuming and expensive. To keep your budget and timeline intact, make sure you:

- Research realistic pricing estimates for various cost factors, including maintenance, training, software updates, support, and platform licensing fees.

- Evaluate the total cost of ownership while considering the direct and indirect costs that you might incur over the system’s lifespan.

- Allocate your budget based on the above estimates.

- Have a phase-wise breakdown of the implementation project and create specific timelines, milestones, and steps for each phase.

- Build in room for flexibility in your schedule, so you can prepare for unforeseen issues and delays.

Risk mitigation and troubleshooting

Implementing a new WMS comes with significant risks, as you have to deal with a complete technology overhaul. Mitigating these risks is a crucial part of effective supply chain risk management, so you should:

- Thoroughly evaluate the new WMS’s compatibility with your existing tech stack, user-friendliness, and integration capabilities.

- Accurately and consistently format all your data to prepare for migration.

- Prepare comprehensive data backups to prevent permanent data loss during the migration process.

- Make sure that all operational areas are covered during testing.

- Catch and fix glitches and compatibility issues as soon as possible.

- Collect user feedback to identify any issues with functionality or usability.

- Make adjustments based on user feedback and test results.

- Set up a dedicated support team to offer help in case any issue arises during your system go-live.

Measuring ROI and success metrics

Even after deployment, you must constantly monitor performance to ensure successful implementation. The following steps will help you measure ROI while further optimizing your operations:

- Define and track success metrics to measure performance at different warehouse processes. This may include KPIs like inventory accuracy, warehouse productivity, on-time fulfillment rate, order cycle time, and so on.

- Set up benchmarks to help you understand how the new WMS is affecting the above metrics.

- Establish timelines of measurement so you can compare performance at realistic intervals.

- Schedule regular reviews and feedback sessions to facilitate continuous improvement.

Real-world example: Elwood Clothing

As Elwood Clothing expanded their product line to 3,500+ SKUs, managing them all on Shopify alone got too complicated — and unsustainable. They needed a more robust and comprehensive solution to support their operations.

Enter the ShipBob WMS, which enabled them to keep their existing inventory and warehouse facility while still optimizing their warehouse operations.

With a dedicated representative coming on-site to set up the WMS, it took just a couple of weeks for Elwood Clothing to revamp their entire logistics operation. Their ShipBob onboarding specialist came out to their warehouse to show them how to set up all their inventory storage locations, hardware, and software in-person.

With ShipBob’s WMS powering their fulfillment, Elwood has been able to fulfill 70,000 orders per month during peak season, and save $200,000/year on shipping thanks to the ShipBob WMS’s built-in carrier selection algorithm.

“Implementing ShipBob’s WMS in our warehouse was so much easier than I expected, because ShipBob sent a representative out to our warehouse for a couple of weeks to essentially revamp our entire operation.

We got new racking and equipment, and they showed us how to set up all our inventory storage locations, hardware, and software, including both their desktop and WMS application (ToolBob) for managers and the mobile app for pickers (MiniBob).

Most importantly, they didn’t leave until everything was right. It wasn’t like they had a deadline for finishing the setup, and if we didn’t meet it, we’d have to finish on our own – not at all. Instead, they took their time and made sure we were in a good place and were comfortable operating independently before they left. They never left us high and dry.

Having someone right there with us to walk us through the whole implementation process in-person was amazing. We also had an Implementation Manager, Lacey, who helped coordinate all the onboarding and training for me and my team, which was awesome as well. Overall, we had so much support, and it really made the transition seamless.”

Tim Poyer, VP of Operations and Logistics at Elwood Clothing

Considering external WMS consultants

External WMS consultants can be a game-changer for your implementation success, provided you’re working with the right ones. With years of industry expertise and in-depth system knowledge, the right WMS consultants can give you hands-on assistance in implementing the system for your operation.

In addition to helping you set up the software and hardware, they can provide hands-on training on how to work the system. Not to mention additional insights and suggestions on how to optimize your warehouse setup for greater efficiency.

However, it all boils down to working with WMS providers who don’t take a hands-off approach to system integration. Many providers simply help you set up the system and leave you to figure it out on your own. Be sure to check client testimonials and reviews, and ask plenty of questions during the vendor vetting process.

“Our ShipBob Implementation Specialist helped us tremendously during the WMS onboarding. Structurally, the way we had our warehouse set up was fine. We didn’t need to move racks or pack tables, but our processes needed to be reworked.

Luckily, we had a lot of support. ShipBob sent our Implementation Specialist out to our site to help us get our warehouse up and running. He basically set the system up for us. When he was done, he gave us the greenlight to start using it and it worked perfectly. The hands-on onboarding from ShipBob taught us how to create efficient pick paths.”

Adam LaGesse, Global Warehousing Director at Spikeball

How a well-implemented WMS enables advanced ecommerce workflows

When a WMS is well-implemented and working properly, it’s magic for your warehouse operations. Here are just some of the advanced workflows that a WMS streamlines, and how ShipBob’s WMS goes above and beyond to optimize them further.

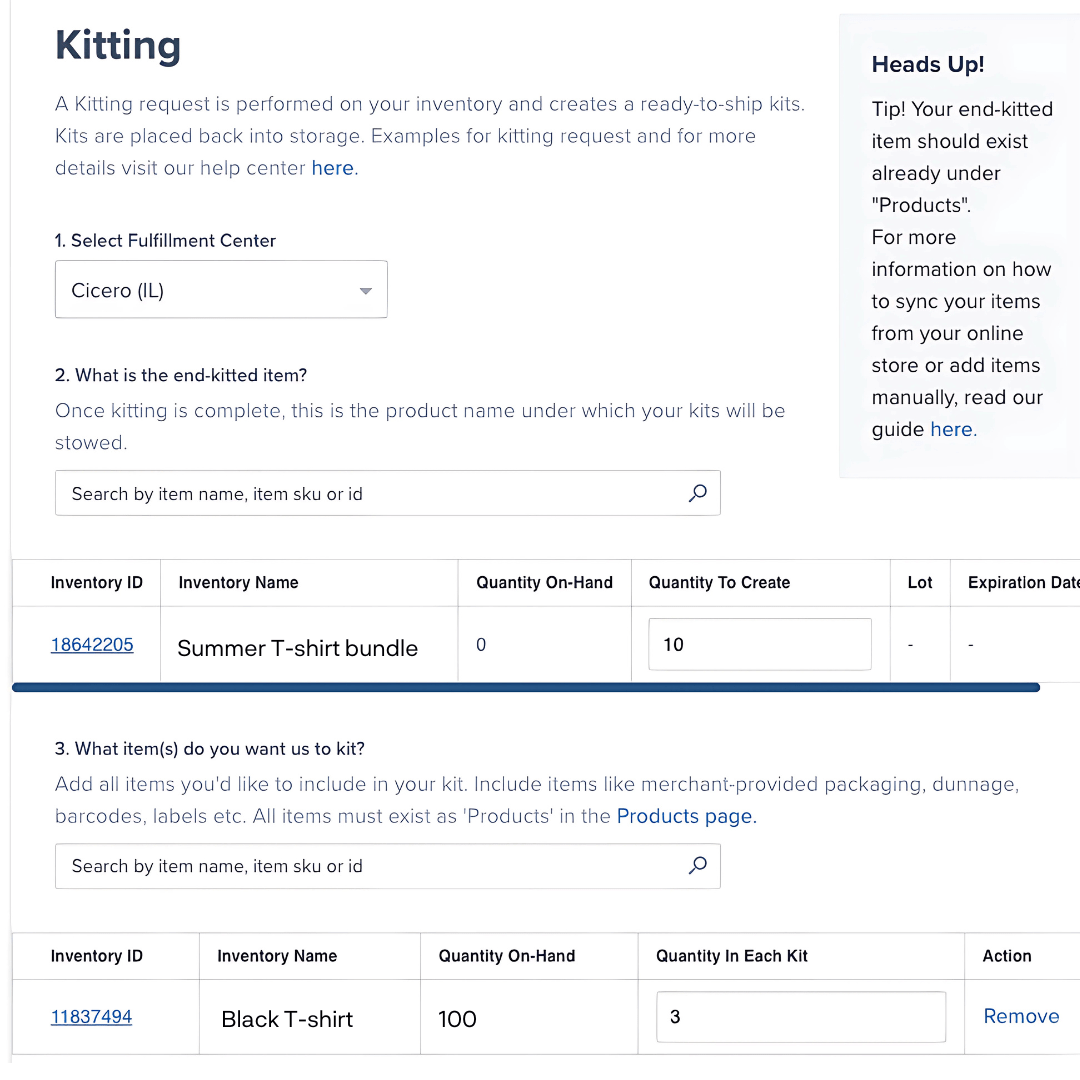

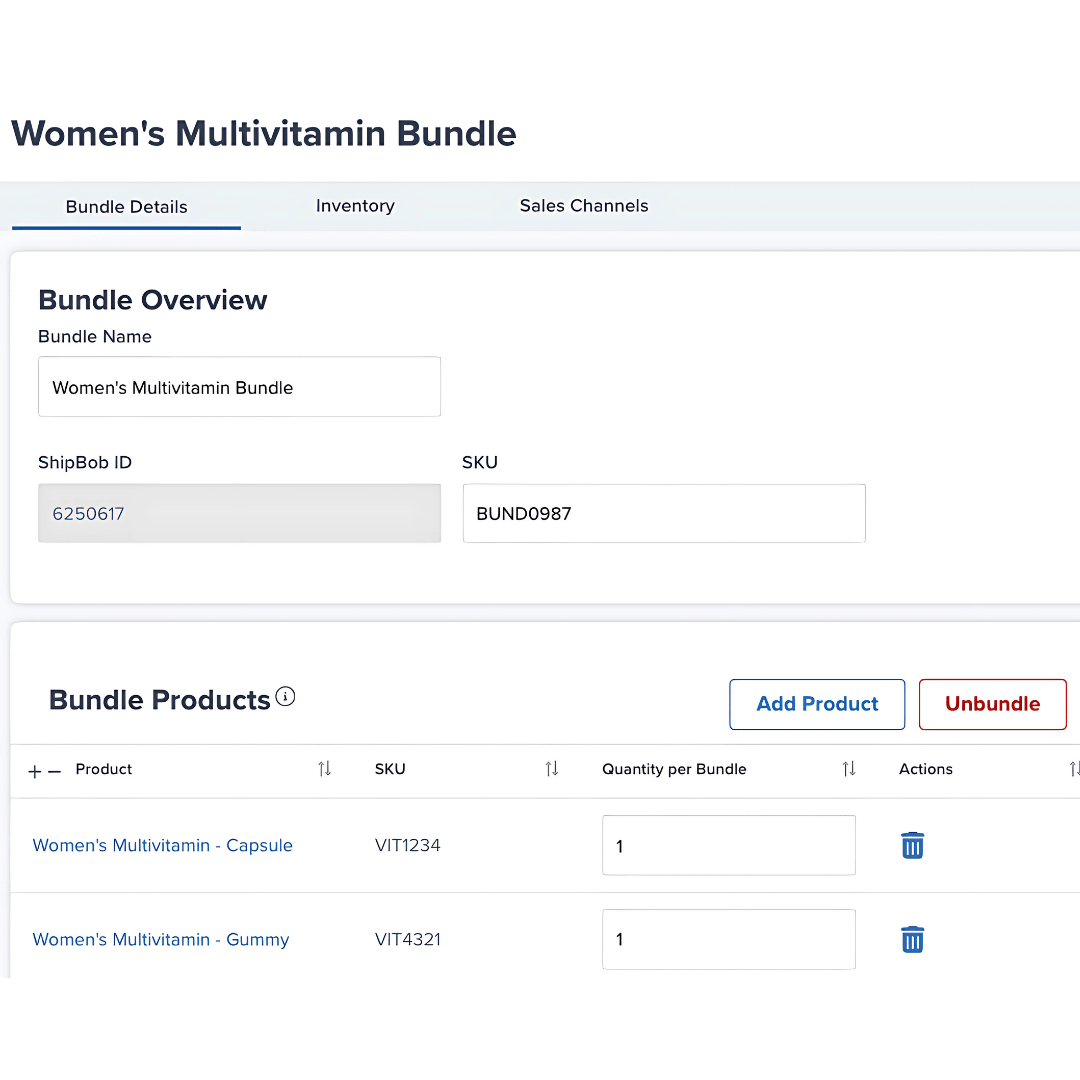

Kitting, bundling, and subscription box management

Kitting, bundling, and managing subscriptions are all very complicated, time-consuming endeavors — but the right WMS can help you automate much of the tedium and logic involved.

ShipBob WMS comes with powerful features to manage kitting, product bundling, and subscription boxes. You can easily create kits and bundles and even modify them from the ShipBob dashboard. You also get accurate insights into your inventory levels, whether you choose to sell products individually or as part of a kit or bundle.

ShipBob WMS also features our Customization Suite of features, which lets you add custom-branded packaging and personalized inserts to orders to create a memorable unboxing experience to retain long-term subscribers.

Bloom Nutrition

Our Place

Cowboy Colostrum

Handling returns and reverse logistics

Returns are difficult to process manually; with a WMS, they get a whole lot easier.

With ShipBob’s WMS specifically, you can easily optimize your returns management process using various tools and integrations. The platform integrates with leading returns management platforms so you can manage the entire process and track returns logistics in one place.

ShipBob also offers flexibility when it comes to managing returned items. You can choose to have them restocked, quarantined, or disposed of based on the type of product and return reason.

Serial and lot number tracking

When you sell perishable products, it’s absolutely critical to track lots and monitor freshness. A good WMS will have the ability to track that information for you, ensuring better traceability and making product recalls easier.

ShipBob WMS, for example, includes lot tracking capabilities that allow you to assign a lot number to specific items, and store lots separately to avoid confusion and costly mispicks.

ShipBob WMS also uses the first in, first out (FIFO) inventory allocation logic designed to identify shelves that contain items with an expiry date first and always ship the nearest expiring lot date first, so you can maximize ROI on your inventory and avoid deadstock.

“Many of our products have expiration dates, so it’s incredibly important for us to track and maintain inventory freshness – and ShipBob’s lot control features make that really easy.

When we send new inventory to ShipBob, all we have to do is mark it as a lot product in the ShipBob dashboard and list the lot number and expiration date for each lot on the warehouse receiving order (WRO). From there, ShipBob handles receiving and stores each lot separately for trackability and so there’s no confusion when it’s time to pick.

At our scale, it would be impossible to manually check the expiration date of every single unit we ship, so leveraging ShipBob’s lot capabilities gives us much more peace of mind.”

Neil Blewitt, SVP of Operations at Bloom Nutrition

Preparing for international expansion

If an international expansion is in the cards, a robust WMS implementation helps you lay the foundation to effectively scale your operations.

ShipBob’s international fulfillment network makes sure you’re covered when it’s time to take your business across the borders. You can strategically leverage this network to streamline global shipping, and minimize cross-border complexities.

“Distributing inventory across the world with ShipBob drastically cut our transit times. When we were only shipping from our Miami, FL warehouse, it would take us 25 days to deliver an order to a customer in the EU, while using ShipBob’s UK fulfillment center, it takes only 3 days. That’s an 88% reduction in shipping time for those international customers!”

Rachel Tannenholz, President of Aroma360

Turn your warehouse into a competitive advantage with ShipBob’s WMS

With powerful capabilities to support different aspects of your warehouse operations, ShipBob’s WMS holds the key to unlocking ecommerce success. It serves as an all-in-one platform to give you better control over everything from warehouse and inventory management to order and transportation management.

ShipBob offers best-in-class implementation services and dedicated support, including:

- Virtual or on-site implementation with zero down time, led by operations experts

- Complimentary warehouse efficiency and change management consultations

- Dedicated Account Manager for one-on-one support and quick troubleshooting

- Ongoing strategic planning, product education, and operational optimization

To learn more about ShipBob WMS and our implementation process, click the button below to get in touch.

WMS implementation FAQs

Below are answers to the most commonly asked questions about WMS implementations.

What’s the typical timeline for a WMS implementation?

The timeline for a WMS implementation varies depending on factors like the level of customization and the complexity or size of your operations. Implementation timelines typically range between 3 and 12 months.

How do I integrate a WMS with my ecommerce platform or ERP system?

Many WMS platforms like ShipBob come with pre-built integrations for leading ecommerce platforms or ERP systems, so you don’t have to complete a manual WMS integration process. Alternatively, you may also use API capabilities to support the integration process.

Why is change management vital for successful WMS implementation?

Effective change management is vital for minimizing resistance during a WMS implementation. It also drives user adoption, improves understanding, and ensures a successful transition to the new system.

Should I hire an external consultant for my WMS project?

Hiring an external consultant for your WMS project is usually recommended if you lack internal expertise to oversee successful deployment. Complex projects also require an external consultant. You may also want to consider working with a consultant if you lack the time and resources to manage it in-house.

How do I measure ROI after WMS implementation?

You can set benchmarks and monitor certain warehouse KPIs to measure the ROI of your WMS implementation project. This will involve important performance metrics across various warehouse operations, including order fulfillment, picking, packing, and receiving.

Can ShipBob’s WMS handle advanced workflows like kitting or subscription boxes?

ShipBob’s powerful WMS can support advanced workflows, such as kitting and subscription boxes. The platform comes with a customization suite to meet your unique fulfillment needs, including branded packaging and even customizable gift notes.