Verified & Reviewed

Last updated on August 8, 2025 Written By Rachel Hand

Last updated on August 8, 2025 Written By Rachel Hand

Subscribe for More

Even though people are shopping in multiple ways (online, in store, through apps, etc.), they still expect everything to work smoothly together. As a result, businesses now need to make sure the shopping experience feels the same across all these options. To keep up with what customers want, it’s important for companies to use an omnichannel supply chain that connects everything.

In this post, we’ll walk through what an omnichannel supply chain is, how your business can benefit from it, common challenges, and how to upgrade your omnichannel supply chain to achieve sustainable growth.

What is an omnichannel supply chain?

An omnichannel supply chain refers to a single supply chain that coordinates producing, transporting, and delivering goods for all of a business’s sales channels.

Essentially, rather than having a separate supply chain for each sales channel a business uses (i.e., one for their ecommerce store, one for their retail business, one for their Amazon store, etc.), a business has one supply chain that manages all of its sourcing, production, and product distribution.

An omnichannel supply chain seamlessly integrates operations for different sales channels and ensures a smooth flow of goods between them for effective omnichannel fulfillment.

Key components of an omnichannel supply chain

There are several elements that are crucial for building an omnichannel supply chain.

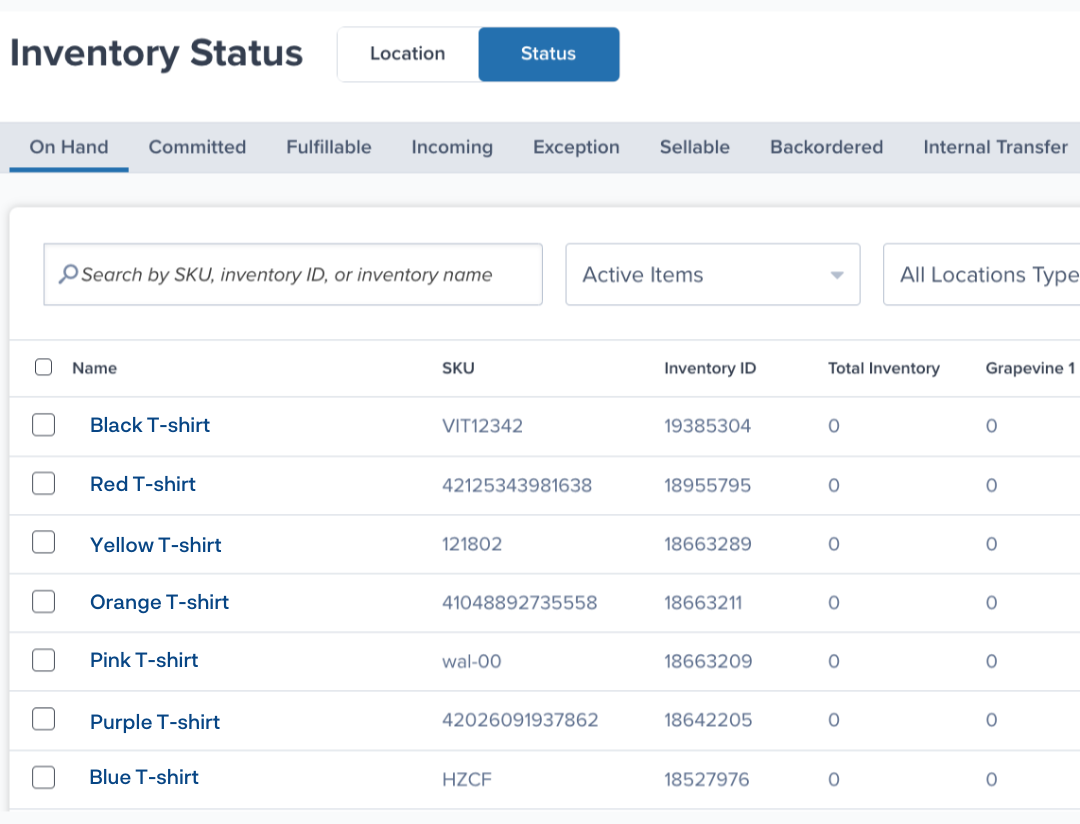

Unified inventory management

Inventory data is shared in real time across all digital and physical channels. This provides the business with real-time visibility into stock levels, and to sync inventory counts across channels using a single pool of inventory.

This lets customers view what’s in stock and purchase it through their preferred channel, without the business having to worry about accidentally selling stock they don’t have.

Automated order processing

Orders are processed automatically using a centralized order management system. This ensures that order information is automatically shared across relevant channels, which kickstarts the fulfillment process.

Personalized shopping experiences

An omnichannel supply chain lets you pass and share relevant data across various channels, which allows you to deliver personalized experiences for each customer.

For instance, you can tailor your business’s offers and ads to appeal to individual shoppers across various touchpoints and channels.

Cross-channel fulfillment

In an omnichannel supply chain, businesses can offer flexible multi-channel fulfillment options so that customers can choose how they’re like to receive their order. For example, shoppers could choose to buy online and pick up in-store (BOPIS), opt for curb-side pick-up, ship-from-store to get the order shipped to their doorstep, and more.

Streamlined logistics

With only one supply chain to manage, a business can greatly streamline their procurement and logistics operations. More importantly, information and tracking data are shared in real-time with relevant parties, which helps maintain visibility and address possible delays that could disrupt operations.

Benefits of adopting an omnichannel approach

Implementing an omnichannel approach to supply chain management benefits ecommerce businesses in a number of ways.

Consistent customer experience

An omnichannel retail supply chain ensures that your customers can enjoy a consistent shopping experience, no matter which channel they use to interact with your brand.

Whether they decide to browse online or visit your brick-and-mortar store, customers can pick up right where they left off on a different channel and enjoy an uninterrupted shopping experience. This significantly boosts customer satisfaction, which eventually contributes to better customer loyalty.

Increased sales opportunities

With an omnichannel supply chain, ecommerce stores can sell on more channels, more easily. This helps you meet customers where they are, and opens up more platforms for customers to browse and buy — no matter which channel they decide to use.

Not only does this lower the chances that a customer will go somewhere else to find the product they’re looking for, but it also creates more opportunities to generate sales and drive revenue for your business.

Enhanced supply chain efficiency

With the automation and real-time inventory syncing central to an omnichannel supply chain, you can significantly speed up various operational processes. As a result, you can reduce shipping and fulfillment times, allowing you to enjoy increased supply chain efficiency.

Understanding the difference between omnichannel and multichannel supply chains

At first glance, omnichannel and multichannel ecommerce strategies may seem similar enough — after all, both involve businesses maintaining a presence across different channels, so customers can interact with them through both online and offline channels.

The key distinction is that in omnichannel ecommerce, the channels are seamlessly connected to provide a unified experience. Meanwhile, in a multichannel supply chain, different sales channels typically function on their own, with siloed systems and minimal visibility.

Integration vs. independence in channel management

In omnichannel supply chains, the different channels are integrated to create a seamless shopping experience. That means customers can easily switch from one channel to the other without interrupting their buying journey. Pricing and support are consistent across these channels, allowing customers to enjoy a unified experience.

In a multichannel supply chain, on the other hand, different channels function independently. With less data exchange and synchronization, there’s a risk of disruptions and disconnect that could negatively influence the customer experience. For instance, inventory information may be out of sync, leading online stores to display items as available even when they’ve run out of stock in stores and distribution centers.

Customer engagement comparison

Due to various touchpoints being interconnected in an omnichannel supply chain, customers can seamlessly engage with the brand no matter which channel they use.

For instance, they can browse products online, check in-store availability, buy them online, and choose to pick them up from the store on the same day. They may also be able to use an app to locate products in-store or use AR technology to view the products in their homes.

Meanwhile, customer engagement across different touchpoints in a multichannel supply chain tends to be inconsistent and disconnected. For instance, customers may see lower prices online compared to in-store prices, or they may have no way to check if the product they’re viewing online is available at a nearby store.

Challenges in omnichannel supply chain management

Although an omnichannel supply chain ultimately improves your bottom line, managing one comes with a few complexities. These include:

- Data consistency: Without the right technology, businesses can struggle to maintain consistent product information and inventory data across various channels. This often leads to a disconnect between different channels, resulting in inaccurate data.

- Inventory discrepancy: Inventory systems may fail to sync in real-time across different channels (which is common for brands dealing with high order volumes and high in-store traffic with fast-moving products). As a result, there’s a higher risk of stockouts, overstocking, and miscommunications.

- Omnichannel fulfillment: it can be hard to efficiently fulfill orders across different channels — especially without a fulfillment partner. Businesses have to deal with logistics complexities to ensure that orders across every channel are fulfilled efficiently while keeping shipping times and costs low.

Integrating technology solutions

Some of the biggest challenges that come with omnichannel supply chains can be solved through integrating your technology.

When your various ecommerce platforms and technology solutions are seamlessly connected, order information and relevant inventory data are automatically shared. This removes a lot of the manual workload of managing multiple channels, and reduces the opportunity for human error.

For instance, ShipBob’s fulfillment platform integrates with leading ecommerce websites and other tools so that various sales channels are connected. This helps you maintain real-time inventory visibility by collecting data on your offline and online orders and updating inventory information across all your sales channels. It supports automated order processing and ensures that stock levels in your inventory platform are updated accordingly.

With this level of accuracy, you can access consistent inventory information across every sales channel and use it to inform other aspects of your operation, such as procurement and inventory planning. You’ll be able to accurately forecast demand, make timely replenishment orders, minimize backorders, and prevent the risk of stockouts.

Case studies of successful integration

Want to know what a real omnichannel supply chain looks like? Check out these top ecommerce brands to see how omnichannel logistics changed the game for them.

Our Place

ShipBob’s sophisticated technology and distributed fulfillment network played a crucial role in the omnichannel success of Our Place. With an API that’s agnostic to the merchant’s preferred backend solution, Our Place was able to seamlessly collect order data from various channels to unify their fulfillment operations.

The viral cookware brand also relied on ShipBob to handle both DTC and B2B orders, maintaining unified inventory across all channels. In addition to fulfilling DTC orders online, Our Place was able to seamlessly expand their presence through retail channels such as Nordstrom, Bloomingdales, Target, and Saks.

By managing all these orders through ShipBob’s warehouse network and expanding to four warehouses, the brand significantly reduced their freight costs. They’ve since been able to save $1.5 million in freight costs while reducing fulfillment speed by 50%.

“For us, technical prowess holds equal significance to operational excellence. Comparing ShipBob’s platform to other fulfillment providers, it’s challenging to find a match for its extensive technical capabilities.”

Ali Shahid, COO of Our Place

Taste Salud

For Taste Salud, selling through multiple channels was a major reason for their business going from $350k in sales in their first six months to $4 million sales in 2022, which then tripled in 2023. While the brand was already fulfilling their DTC orders through ShipBob, they were able to leverage ShipBob’s B2B fulfillment solutions to expand to other channels such as Walmart, Target, and Amazon.

With ShipBob serving as a single source of truth for all these sales channels, Taste Salud was able to access real-time inventory data to inform their decisions. The platform’s built-in reporting provides valuable data on inventory levels at various fulfillment centers, average fulfillment time, and cost of fulfillment to make data-backed decisions.

Additionally, as the brand was constantly experiencing stockouts during their first couple of years, they wanted to maintain optimal inventory levels at every location. The ShipBob Inventory Placement Program allowed them to strategically improve their inventory allocation and ensure inventory availability. As a result, customers have been able to receive their orders in just a couple of days.

“Running your own warehouse, you have to go out and hire very experienced people, invest in equipment, build in automation – and often, you’re wasting a lot of time, energy, resources, and human capital for a sub-par result. Why do that when a partner like ShipBob exists, and makes fulfillment so easy at a fair price?”

Tyler McCann, Co-Founder of Taste Salud

PetLab

For PetLab, being an omnichannel brand is critical to reach more pet lovers across different channels. ShipBob’s DTC and B2B fulfillment solutions have enabled them to keep up with customer demand from all the places where the brand maintains a presence. This includes fulfilling their DTC orders as well as managing fulfillment for other retail websites such as Chewy and Amazon.

The brand has also leveraged ShipBob’s Inventory Placement Program to strategically allocate their inventory across different warehouses to speed up fulfillment. With ShipBob handling all the complexities of their omnichannel logistics operations, PetLab Co. has been able to cut down their logistics team to two people while growing over $100 million in revenue.

“Being an omnichannel brand is critical for us, so we can reach more pet lovers from more places. We’re glad that ShipBob helps us keep up with demand from all the places we reach our customers.”

Stephanie Lee, COO at PetLab

How to upgrade your omnichannel supply chain

If you’re ready to build your own omnichannel supply chain, follow these best practices to enhance efficiency and cost-savings in the process.

Assess your current capabilities

Start with a thorough supply chain audit to get a better understanding of where you currently stand. How is your supply chain functioning right now, and what are you capable of? Which areas need to improve to allow every aspect of your supply chain to work seamlessly together?

Invest in advanced technology

Technology’s role in an omnichannel supply chain is critical. It’s important to invest in advanced technology solutions, such as inventory management software, that will integrate with each other and allow for real-time communication and supply chain visibility.

Optimize inventory placement and management

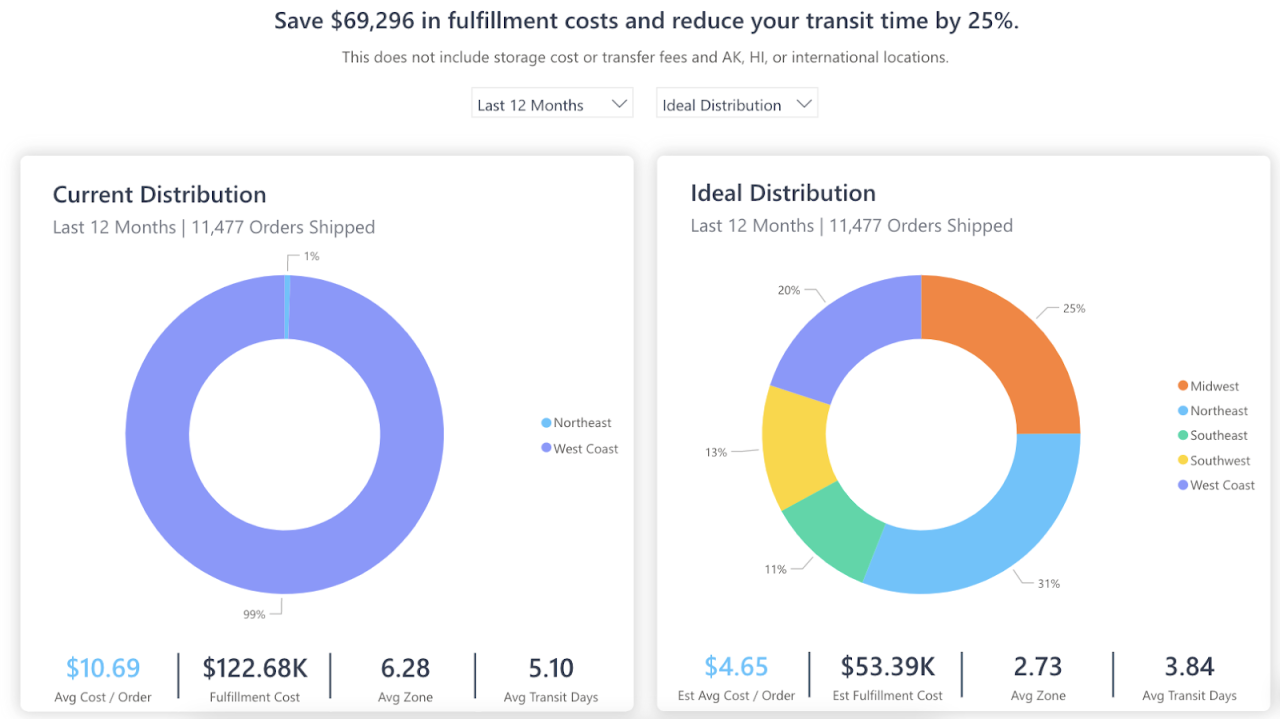

Your inventory placement strategy should be optimized to support an omnichannel supply chain. Distribute your inventory strategically across fulfillment centers and retail partners so you can reach more customers through various sales channels, and do so more quickly and cost-effectively.

Enhance customer experience

Make sure that customers get to enjoy a seamless, consistent experience across all the channels they use to interact with your brand. Consider each touchpoint and find a way to connect the customer experience regardless of the channel.

Improve order fulfillment processes

Optimize your fulfillment operations to improve speed and accuracy. Customers should be able to receive the right orders within the desired timeframe and through their preferred channels.

Build strong partnerships

Your supply chain partnerships play a vital role in the seamless functioning of your omnichannel supply chain. Make sure to find long-term partners who can scale with your business and provide real-time visibility and integrations to support your omnichannel efforts.

ShipBob powers omnichannel supply chains the world over

ShipBob offers flexible and scalable fulfillment solutions to support complex supply chain requirements. Here are just some of the ways that ShipBob can help you take your logistics omnichannel, easily.

Global fulfillment network

With a global network of fulfillment centers, ShipBob lets you store your inventory across various locations to optimize your fulfillment operations. You can leverage ShipBob’s locations to store your inventory closer to your customers and reduce transit time and shipping costs even for international customers.

This supports your omnichannel supply chain by enabling you to easily ship out online orders or restock inventory at brick-and-mortar locations from the nearest fulfillment center quickly and effectively.

“We’re constantly looking at expanding into different markets, so working with a global fulfillment partner was a factor in our decision. While we’re currently only fulfilling orders from the UK, we know that with ShipBob as our partner, we could seamlessly place inventory in new countries and keep everything within the ShipBob platform. If we wanted to start storing products in the US or mainland Europe, we would have a direct connection there because of ShipBob, while allowing us to keep everything within one ecosystem. This is really important as we scale our operations and supply chain.”

Connor Stewart, Head of Operations + Impact at ARTAH

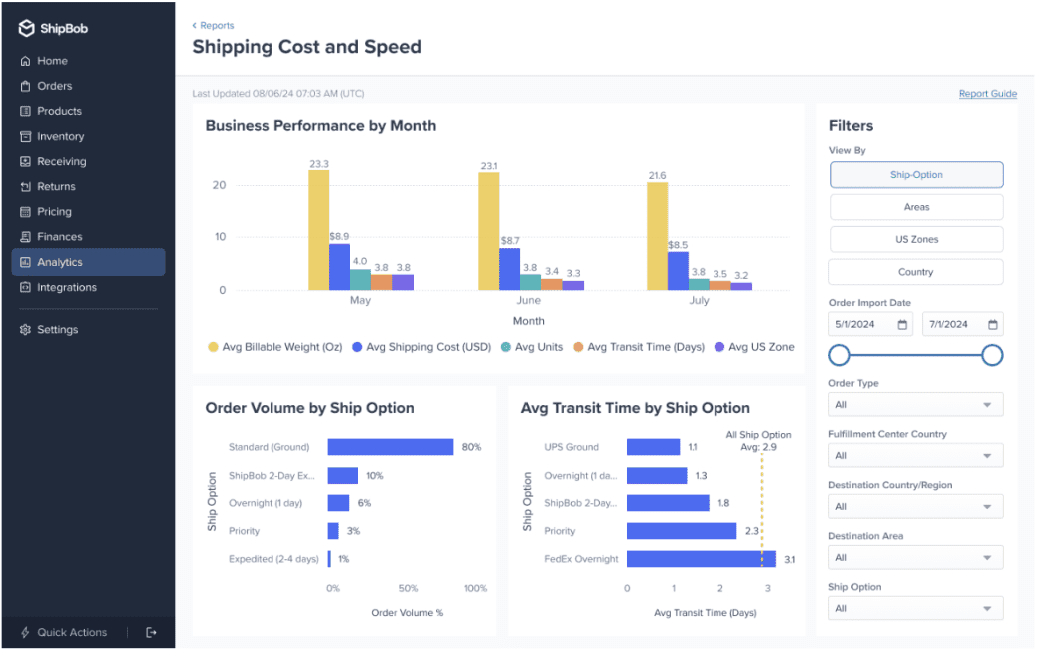

Real-time data and analytics

ShipBob’s powerful analytics and reporting give you a comprehensive look into your inventory and supply chain performance. You can use this tool to extract actionable insights that will inform your supply chain decisions and optimize operations.

In particular, ShipBob’s dashboard provides you with real-time insights into your inventory levels, so you can:

- Anticipate stockout dates.

- Make accurate predictions on your future inventory needs and stock up accordingly.

- See which sales channels are performing well and which you can optimize.

Seamless integration for omnichannel perfection

The ShipBob platform integrates with leading ecommerce platforms and existing merchant software. That way, you can maintain a unified dashboard to seamlessly process orders, share inventory data, and execute fulfillment tasks across various channels.

This allows you to enhance your omnichannel performance by ensuring that all your systems are communicating effortlessly, supporting your operations.

“Our 3 big channels are DTC, marketplaces like Amazon and TikTok, and B2B across the UK and across Europe. We work with over 50 B2B retailers, including ASOS, Boots, and Druni. ShipBob handles our freight, as well as DTC and B2B fulfillment. We have our entire logistics and fulfillment operation under one roof and not split up across different companies. Having a partner that can do it all has been really beneficial for our business.”

Callum Jones, Director of Operations & Marketplace, and Rachel Hicks, Operations Manager at Hairburst

Personalized fulfillment and custom packaging

ShipBob lets you personalize the fulfillment experience for your DTC orders with custom packaging options.

You can ship your products in branded packaging to boost brand recognition or use custom boxes that are perfectly suited for your product’s unique shape and size.

This solution can also optimize your B2B fulfillment process by ensuring that goods are sent to your retail partners in suitable packaging to reduce the risk of damage.

“Our business is complicated – we have a wide variety of products, and we do a lot of customization – but ShipBob’s team has done an amazing job at learning our business, and the technology that drives ShipBob’s packing process ensures that every order gets fulfilled to our particular specifications.”

Melissa Mosheim, Director of Aroma360

Automated inventory allocation and distribution

ShipBob’s network of fulfillment centers allows you to distribute your inventory strategically across various locations. Meanwhile, our proprietary algorithm leverages your business’s actual order data to determine the ideal allocation of inventory across our network to minimize costs and meet your needs.

That means you know exactly where to send more inventory to meet demand, which fulfillment centers are running out of stock, how to reallocate inventory from one location to the other, and more. This strategic distribution allows you to prevent stockouts and overstocking, helping you make the most of your inventory.

“On top of cost savings and fast shipping, we’ve been able to take a more hands-off approach to fulfillment and inventory distribution. We don’t have to be super involved in the day-to-day details and coordination, which is very helpful for our team. IPP works overwhelmingly well. It’s efficient, seamless, and super automated. When you combine that with the fast, personal customer support ShipBob provides us with, it allows us to have full confidence that things are running well.”

Lizzie Vance, Sales Director at P.F. Candle Co.

For more information on how ShipBob can help you build an omnichannel supply chain to help your business scale, click the button below to get in touch.

Omnichannel supply chain FAQs

Below are answers to the most commonly asked questions about omnichannel supply chains.

What are the first steps to transitioning to an omnichannel supply chain?

The first step to transitioning to an omnichannel supply chain is auditing your current supply chain to check your capabilities and assess your needs. Next, invest in advanced software to integrate various channels in your supply chain.

How can small businesses benefit from omnichannel supply chains?

Small businesses can leverage omnichannel supply chains to reach more customers, take advantage of sales opportunities, and enhance the customer experience.

What is the difference between multichannel and omnichannel supply chains?

A multichannel supply chain involves a supply chain network that uses multiple online and offline channels that aren’t necessarily interconnected. Meanwhile, an omnichannel supply chain ensures that all these channels are integrated, so that the customer experience is unified and uninterrupted.